FBG-based full-sea-depth self-adaptive high-precision full-flow penetration spherical probe

A spherical probe and self-adaptive technology, applied in the application of optical methods for fluid pressure measurement, fluid pressure measurement, pressure difference measurement between multiple valves, etc., can solve the problem of sensor explosion range, lack of deep sea environment, and seabed sediment intensity The lack of sufficient understanding of the distribution and change rules of the distribution and change, to achieve the effect of self-adjustment of the range and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

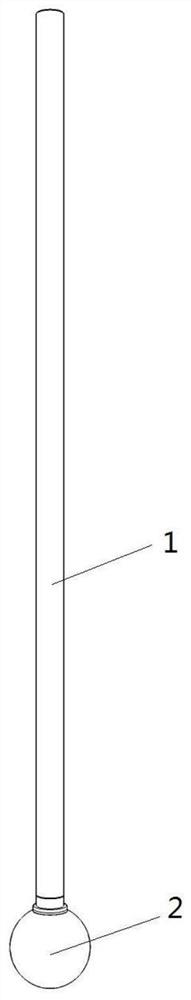

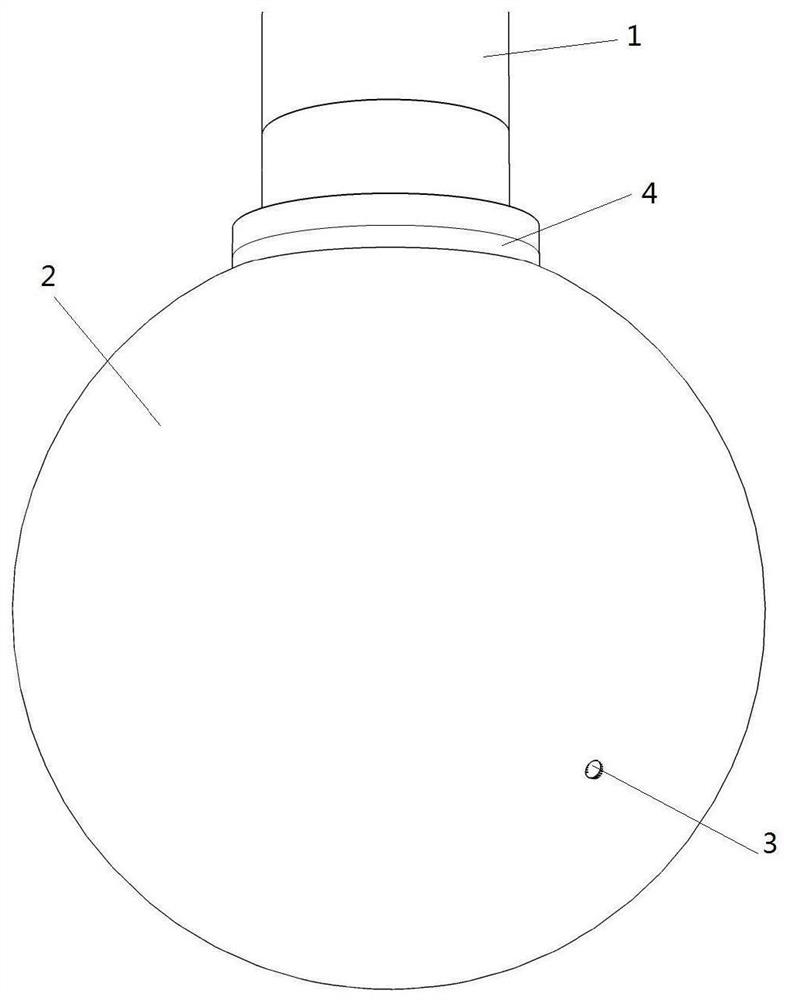

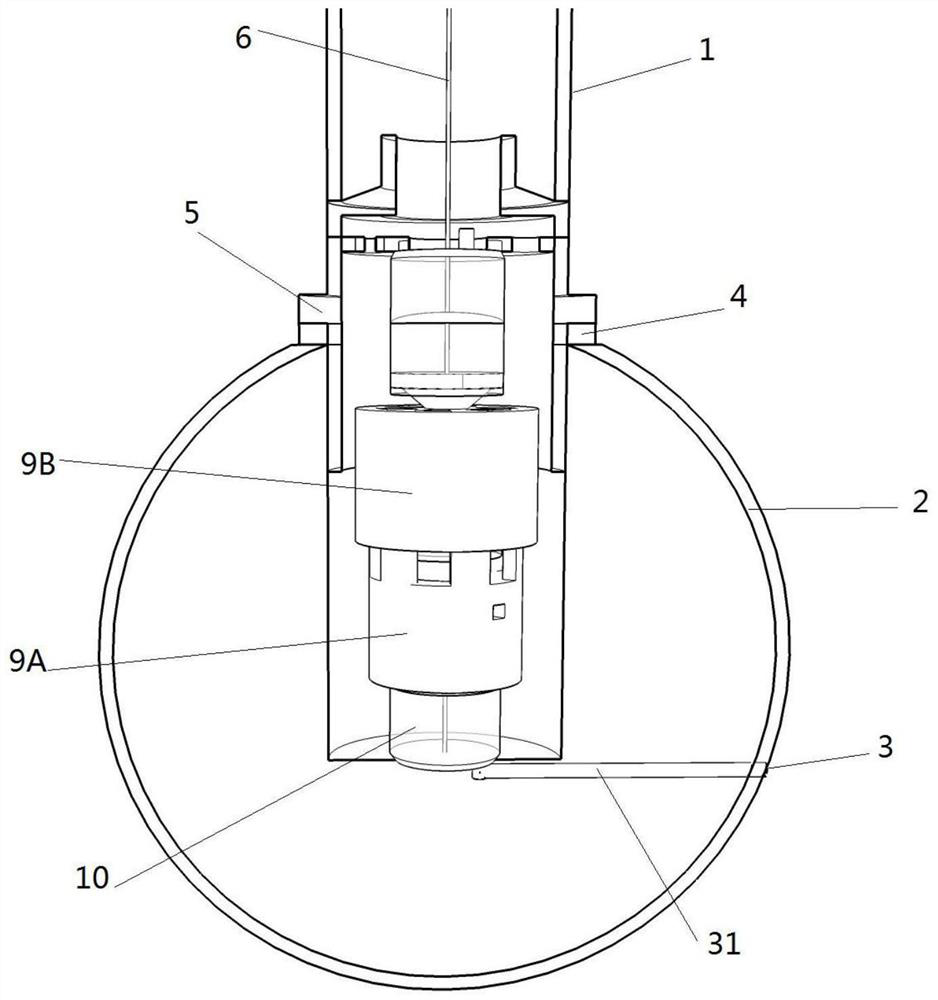

[0027] Embodiment, a full-depth self-adaptive high-precision full-flow penetration spherical probe based on FBG, such as Figure 1-2 As shown, including probe rod 1 and spherical CPT probe 2, probe rod 1 and spherical CPT probe 2 are connected through probe rod connector 5, and buffer glue is also provided between the spherical CPT probe 2 and probe rod connector 5 Pad 4; the spherical CPT probe is also provided with an ultra-porous pressure sensor 10, the spherical CPT probe is provided with a pore-pressure measuring hole 3 and a permeable stone, and the pore-pressure measuring hole 3 and the lower cavity pore-pressure passage of the ultra-porous pressure sensor 10 pass the measurement The channel 31 is connected;

[0028] The spherical CPT probe 2 is provided with a first-order differential pressure sensor (lowest range), a second-order differential pressure sensor (second-lowest range), ... range) and the nth order differential pressure sensor (highest range), where n≥2, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com