Coal pillar test piece coring and sampling method under strong brine soaking effect

A technology of concentrated brine and coal pillar, applied in the field of coal mining, can solve problems such as coal pillar damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

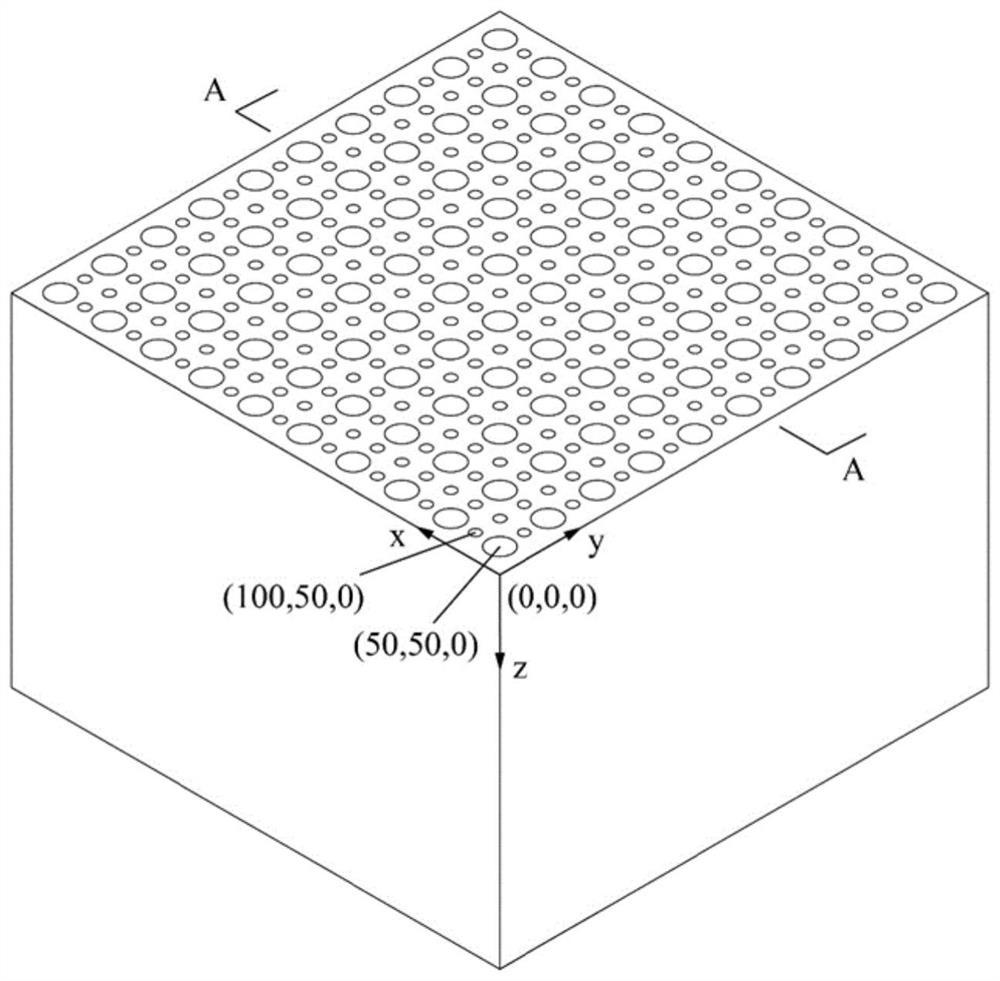

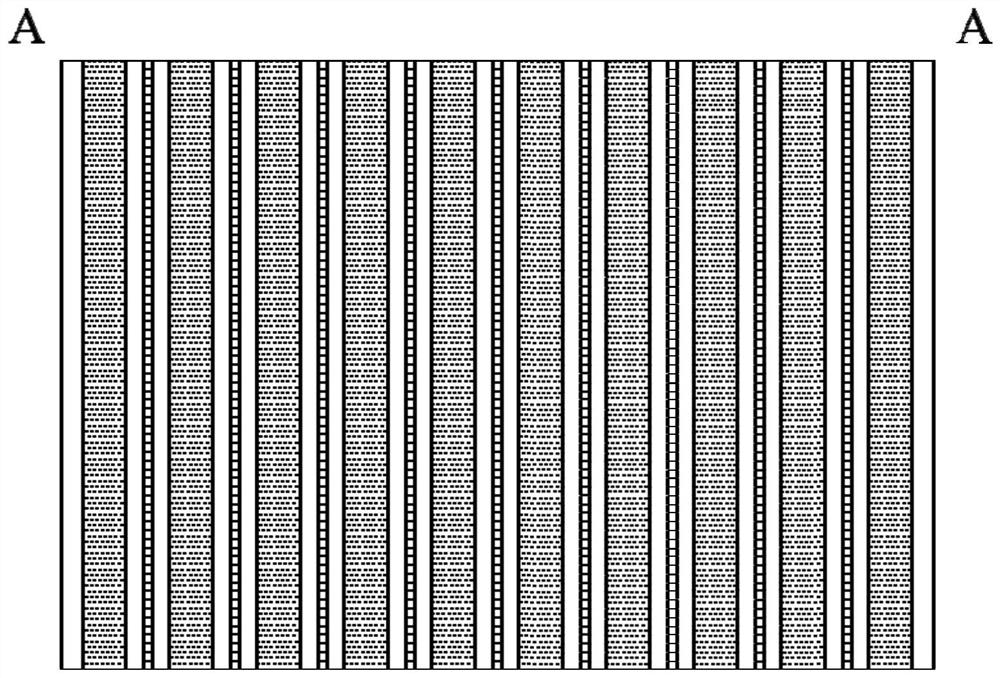

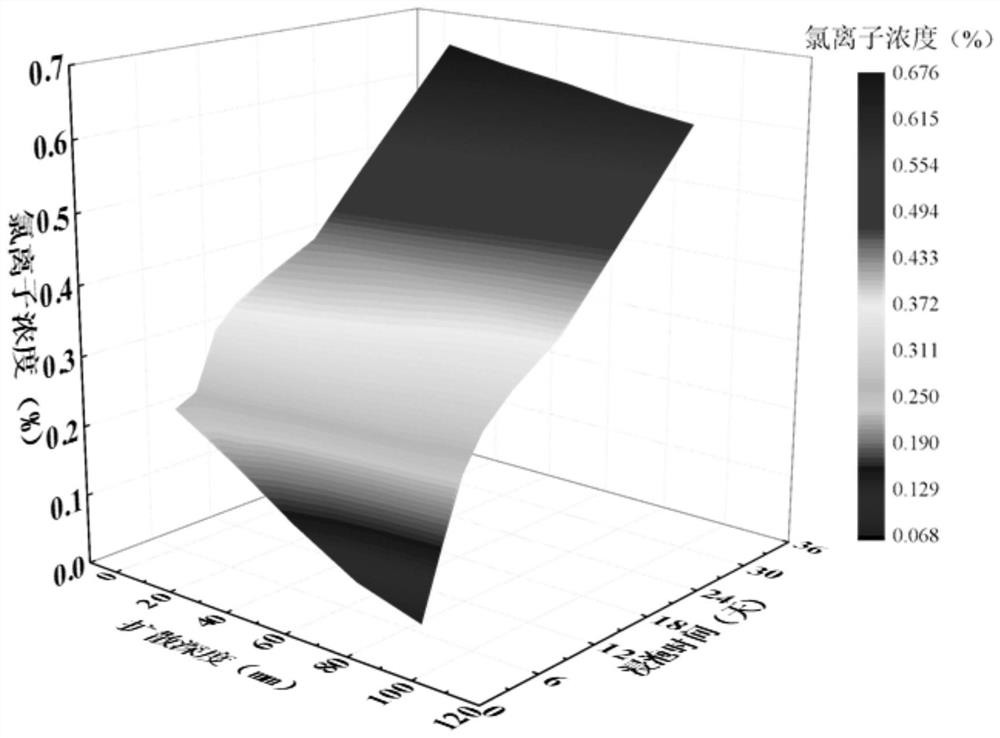

[0032] This example is a specific example of a coal column test piece under a concentrated salt water soaking action, including the following steps:

[0033] (1) Removal salt water soaking coal column test: Remove intact coal blocks that are not submerged from concentrated salt water from the project site, the coal block cutting is machined into a cube coal column test piece with a size of 1000 mm × 1000 mm × 700 mm, after processing The top surface, bottom surface and two non-adjacent sides are applied to the top surface, the bottom surface and the two non-adjacent sides, retain two opposing side as the free surface, and completely soak the coal column test piece in the preformed concentrated salt solution ( In NaCl solution in concentration of 0.1 mol / L, keep indoor constant temperature, simulated natural environment soaking, soaking test period is 180 days;

[0034] (2) Sampling point mark: After the soaking test period is reached, the coal column test piece is removed from t...

Embodiment 2

[0040] This example is a specific example of a coal column test piece under a concentrated salt water soaking action, including the following steps:

[0041] (1) Removal salt water soaking coal column test: Remove intact coal blocks that are not submerged from concentrated salt water from the project site, the coal block cutting is machined into a cube coal column test piece with a size of 1000 mm × 1000 mm × 700 mm, after processing The top surface, bottom surface and two non-adjacent side surfaces are applied to the epoxy resin seal, retain two opposing side as a free surface, and completely soak the coal column test in the preformed concentrated salt solution. Keep indoors constant temperature, soaking out after 3 days, then naturally dried for 3 days, this is a cycle, then soaking it for 3 days after drying for 3 days, so recycled the soaking environment of the simulated dry and wet cycle, soaking the test period of 90 days ;

[0042] (2) Sampling point mark: After the soaking...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com