Tensile shear strength test device

A tensile shear strength and testing device technology, applied in the field of testing devices, can solve problems such as large error in testing results, invalid testing results, and damage to test pieces, and achieve the effects of avoiding deviation, simple and convenient operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

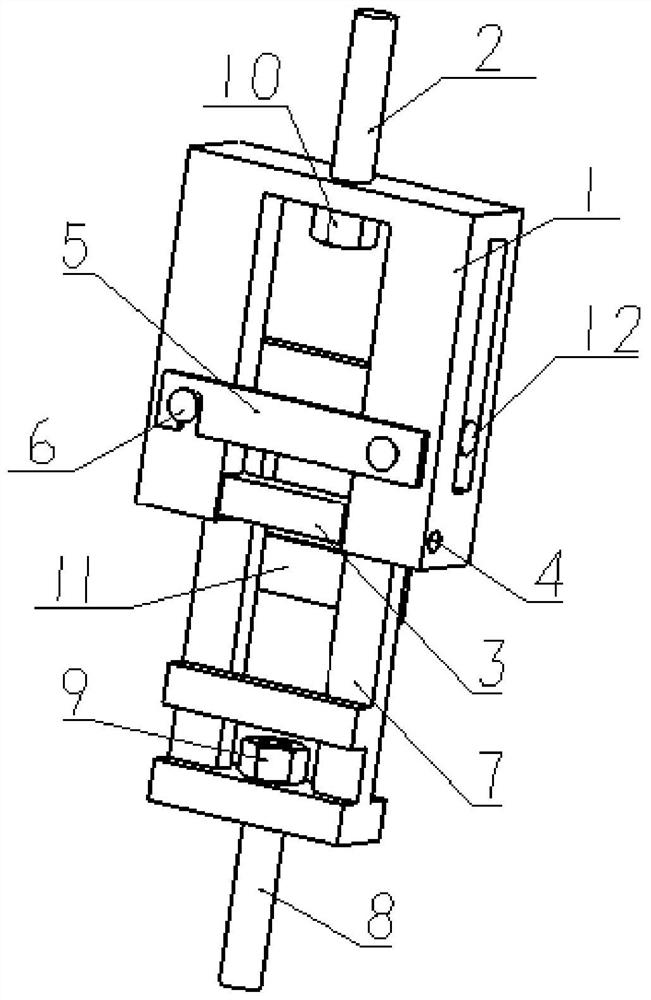

[0036] A tensile shear strength testing device, such as figure 2 As shown, the material is alloy structural steel. The device includes: sample fixing upper frame 1, upper clamping rod 2, upper loading surface of sample 3, fixing pin 4 of upper loading surface, upper baffle plate 5, screw 6, sample Fix the lower frame 7, the lower clamping rod 8, the first nut 9, the second nut 10, the lower baffle plate 11, and the fixing pin 12 of the lower loading surface.

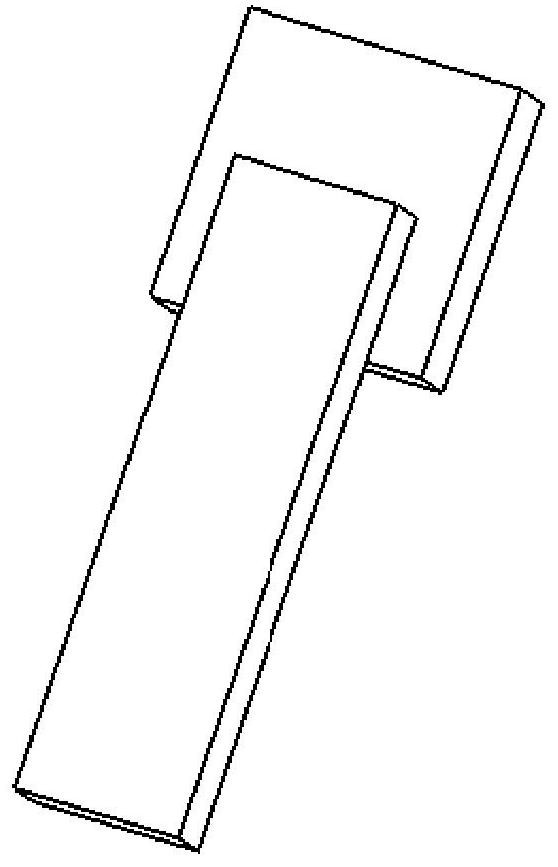

[0037] The upper frame is a rectangular frame without a bottom beam, such as image 3 Shown; There are chute in the left and right side walls of the upper frame;

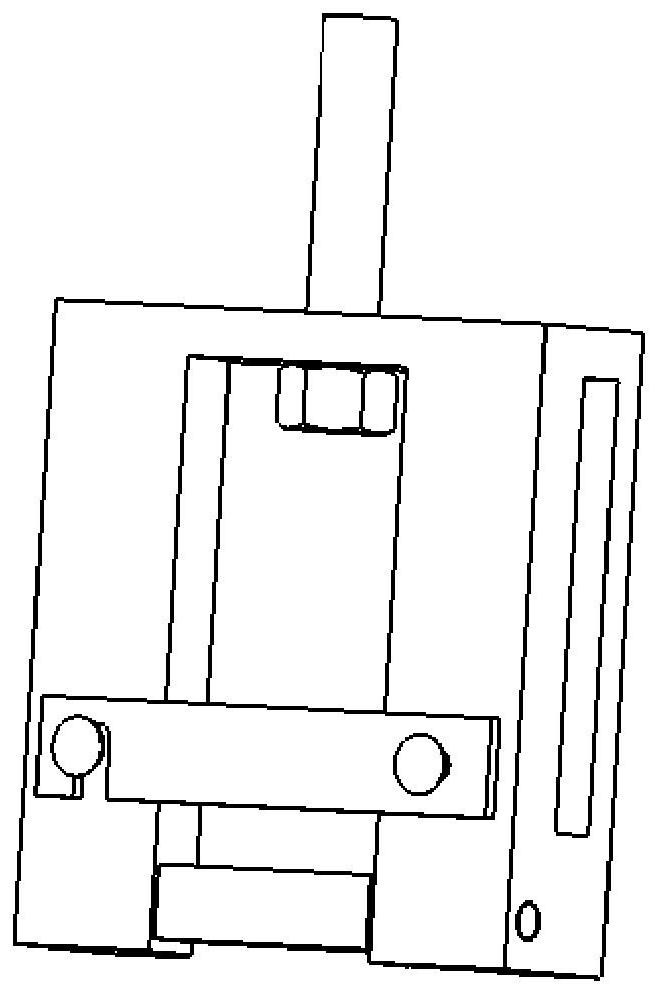

[0038] The lower frame is a rectangular frame, such as Figure 4 As shown; the lower frame is arranged between the left and right side walls of the upper frame; the left and right ends of the top beam of the lower frame are provided with first threaded holes;

[0039] One end of the fixing pin on the lower loading surface is processed with external thread,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com