Defect detection method and device for suspension spring and valve spring and storage medium

A valve spring and suspension spring technology, applied in the field of spring detection, can solve the problems of high cost and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

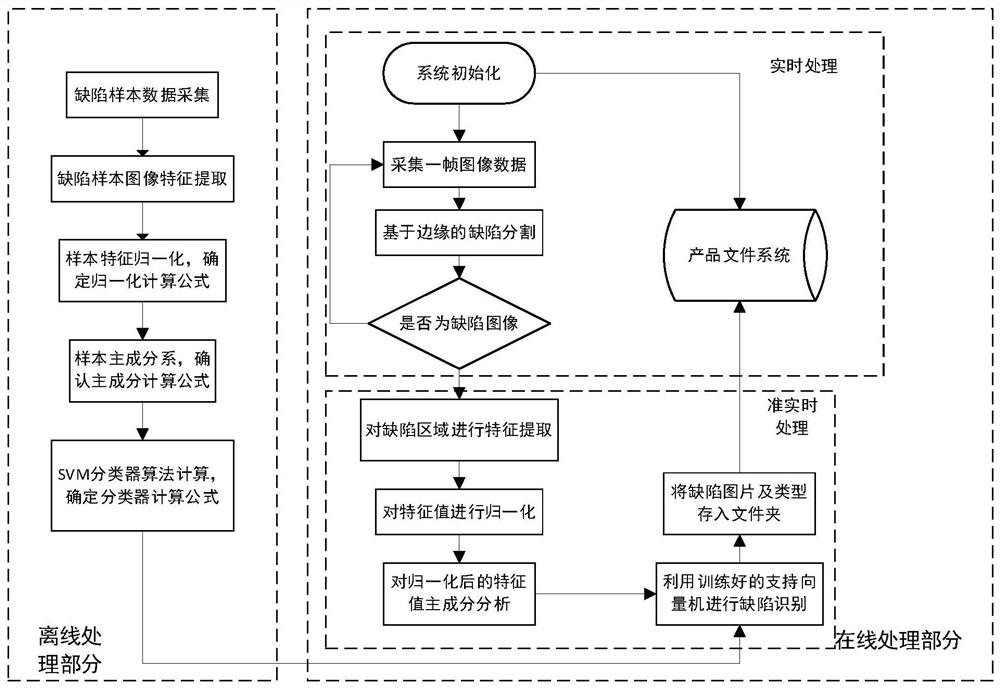

[0106] The present embodiment provides the defect detection method of suspension spring and valve spring, and before it detects, trains a spring defect classifier earlier, as figure 1 As shown, the specific training process is as follows:

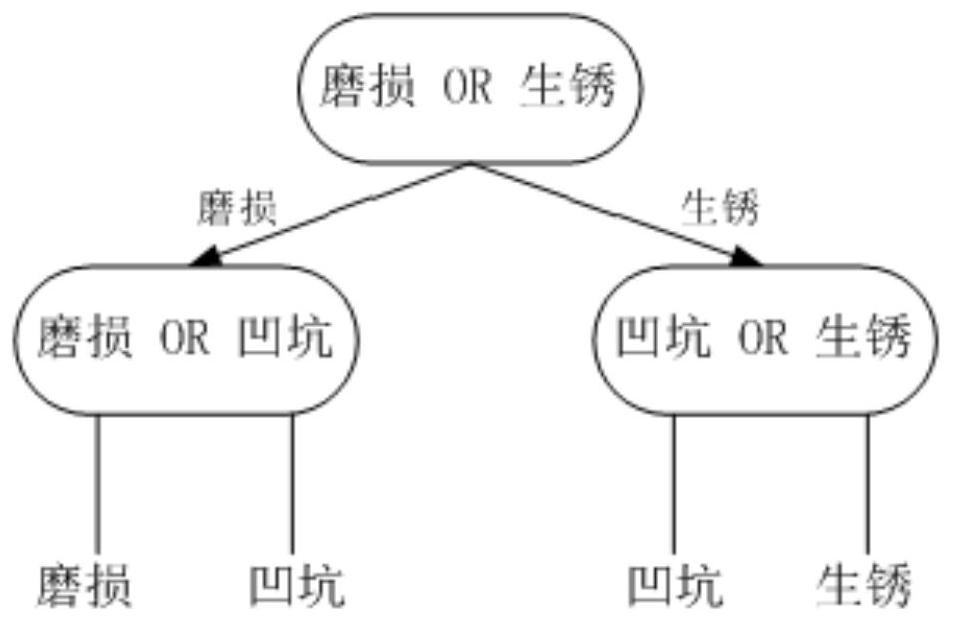

[0107] Step 1: Obtain a number of spring images with defects, including pits, wear, and rust; among the three types of defects, pits are non-background destructive non-pattern background defects, and wear and rust are destructive non-pattern backgrounds defect. When acquiring images, the strip light of the red light source is used, and the low-angle lighting method is selected. The light source is direct light without frosted glass, and the light is illuminated along the axis. This lighting method can convert pit defects into contrasting non-pattern contrasting defects, which is convenient for detection and facilitates the subsequent detection of three types of defects through one algorithm.

[0108] Step 2: adopt sobel operator to carry ...

Embodiment 2

[0197] Such as Figure 7-12 As shown, this embodiment provides a spring defect detection device, including a two-dimensional translation platform 2, a spring installation mechanism 1, a rotation mechanism 3, a camera 5, and an industrial computer 4;

[0198] The spring installation mechanism 1 is installed on the two-dimensional translation platform 2, the rotation mechanism 3 is installed on the spring installation mechanism 1, and the camera 5 is installed above the two-dimensional translation platform 2;

[0199] The two-dimensional translation platform 2, the rotation mechanism 3, and the camera 5 are all electrically connected to the industrial computer 4;

[0200] The spring installation mechanism 1 is used to install and fix the spring 8 to be detected; the two-dimensional translation platform 2 is used to control the spring installation mechanism 1 to reciprocate; the rotating mechanism 3 is used to drive the installed spring 8 to be detected Rotate; the camera 5 is u...

Embodiment 3

[0213] This embodiment provides a computer-readable storage medium, which stores a computer program, and the computer program is suitable for being loaded by a processor and executing the defect detection method for suspension springs and valve springs as described in Embodiment 1.

[0214] Those skilled in the art should understand that the embodiments of the present application may be provided as methods, systems, or computer program products. Accordingly, the present application may take the form of an entirely hardware embodiment, an entirely software embodiment, or an embodiment combining software and hardware aspects. Furthermore, the present application may take the form of a computer program product embodied on one or more computer-usable storage media (including but not limited to disk storage, CD-ROM, optical storage, etc.) having computer-usable program code embodied therein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com