A ±535kv ultra-high voltage flexible DC insulated power cable

A flexible DC and power cable technology, applied in the direction of insulated cables, power cables with shielding/conductive layers, insulators, etc., can solve the problems of increasing the weight of cables, difficult to remove cross-linked by-products, and difficult to recycle and reuse. Achieve the effect of reducing the number of shutdowns for cleaning, continuous production without joints, and reducing the overall consumption of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

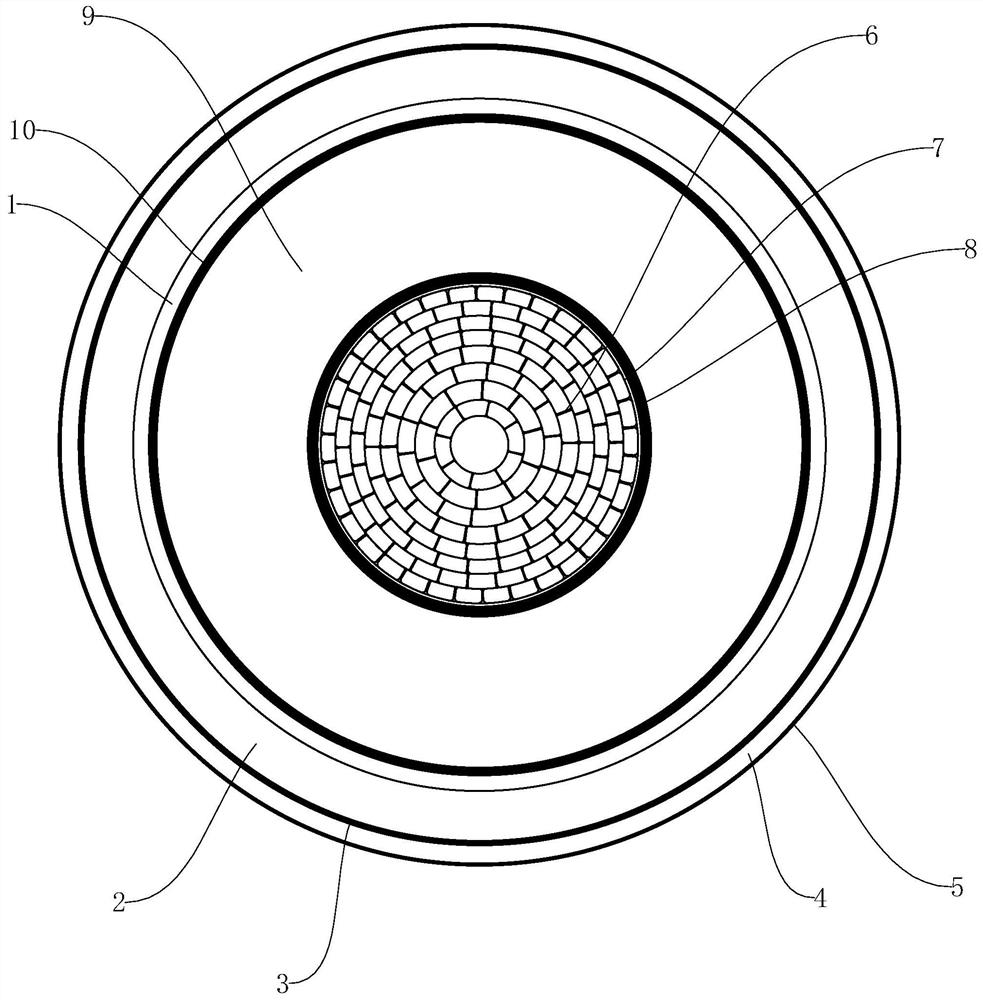

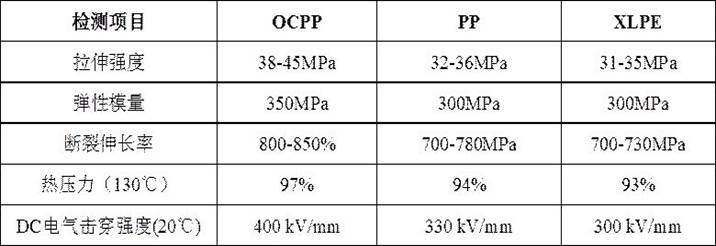

[0020] Embodiment one: if figure 1 As shown, a ±535kV ultra-high voltage flexible direct current lightweight polypropylene insulated power cable includes a direct current unit, a semiconductive resistance water layer 1 is arranged outside the direct current unit, a metal armor layer 2 is arranged outside the semiconductive resistance water layer 1, and a metal armor layer 2 is arranged outside the semiconductive resistance water layer 1. The armor layer 2 is provided with an anti-corrosion layer 3, the anti-corrosion layer 3 is provided with an outer sheath 4, the outer sheath 4 is provided with a semi-conductive layer 5, and the DC unit includes a water-blocking conductor layer 6, which is sequentially arranged from the inside to the outside. The material of the semi-conductive Tedron tape 7, the inner shielding layer 8, the insulating layer 9 and the insulating shielding layer 10 is modified polypropylene, and the material of the inner shielding layer 8 and the insulating shi...

Embodiment 2

[0025] Embodiment two: other is identical with embodiment one, and its difference is:

[0026] In this specific example, the modified polypropylene (OCPP) is made of the following raw materials in parts by mass: polypropylene 85, nanometer organically modified montmorillonite 1.2, calcium hardate 13, acetophenone (AP) 0.5, Sodium hydroxymethyl cellulose 12, rutile nano silica 0.9, wood fiber 1.1, shrinkage uniform additive 0.4, synergistic antioxidant 0.3, nano reinforcement 1.0.

[0027] In this specific example, the synergistic antioxidant includes a primary antioxidant and an auxiliary antioxidant, the primary antioxidant is 4,4'-thiobis(6-tert-butyl-3-methylphenol), and the auxiliary The antioxidants are tris[2.4-di-tert-butylphenyl]phosphite and dolin aromatics, and the weight ratio of the main antioxidant to the auxiliary antioxidant is 1:0.6.

[0028] In this specific example, the nano-reinforcing agent is polyhedral oligomeric silsesquioxane (POSS) with a particle siz...

Embodiment 3

[0030] Embodiment three: other is the same as embodiment one, and its difference is: polypropylene is made of the raw material of following mass parts: polypropylene 105, nano organically modified montmorillonite 1.5, calcium hardate 15, acetophenone 0.8, hydroxymethylcellulose sodium 16, rutile nano-silica 1.0, wood fiber 1.2, shrinkage uniform additive 0.6, synergistic antioxidant 0.5, nano-reinforcing agent 1.2.

[0031] In this specific example, the synergistic antioxidant includes a primary antioxidant and an auxiliary antioxidant, the primary antioxidant is 4,4'-thiobis(6-tert-butyl-3-methylphenol), and the auxiliary Antioxidant is three [2.4-di-tert-butylphenyl] phosphite, dolin arene, and the weight ratio of main antioxidant and auxiliary antioxidant is 1: 1.1.

[0032] In this specific example, the nano-reinforcing agent is polyhedral oligomeric silsesquioxane (POSS) with a particle size of 1.6 nm.

[0033] In this specific embodiment, the uniform shrinkage additive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com