Magnetic floater production equipment and production method thereof

A technology for production equipment and magnetic floats, applied in the manufacture of inductors/transformers/magnets, conveyor objects, packaging/dipping, etc., can solve the problems of low efficiency of floats and low product consistency, and achieve ingenious design and high yield , the effect of high quality float

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

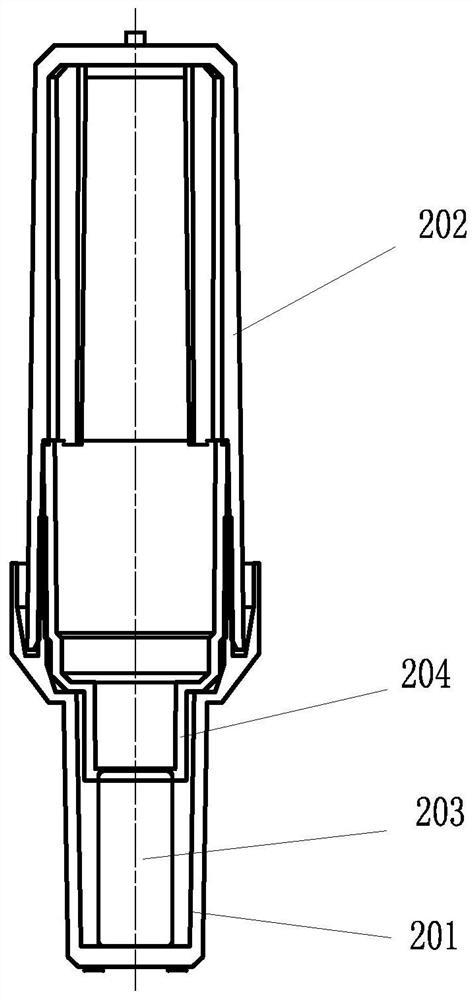

[0033] Please check image 3 , the float includes a bottom cover, a top cover, a magnet and a middle cover. The top cover and the bottom cover are connected to form a accommodating space. The magnet and the middle cover are placed in the accommodating space. The magnet is placed in the bottom cover, and the middle cover is placed in the magnet. Between the top cover and the top cover and both ends abut the top cover and the magnet, under the fixed cover pressure of the top cover and the bottom cover, the middle cover tightly fixes the magnet in the bottom cover and cannot make it move.

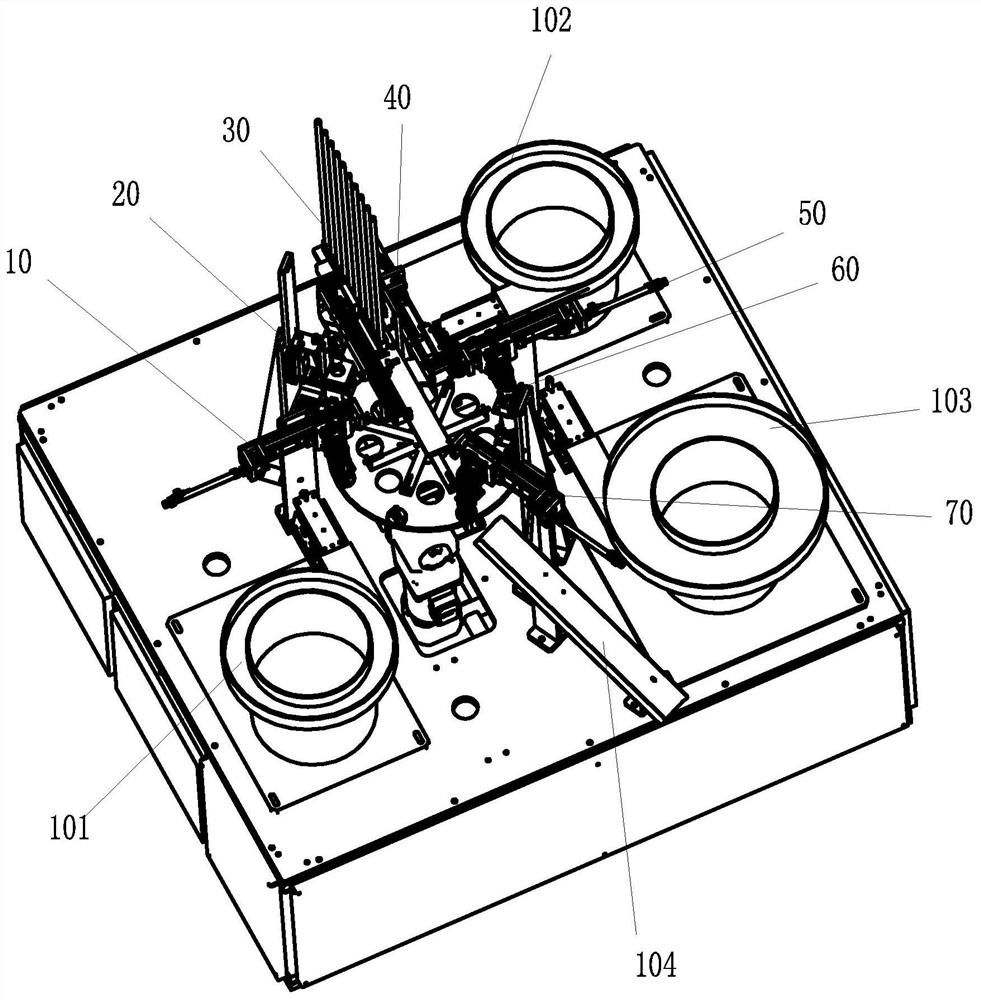

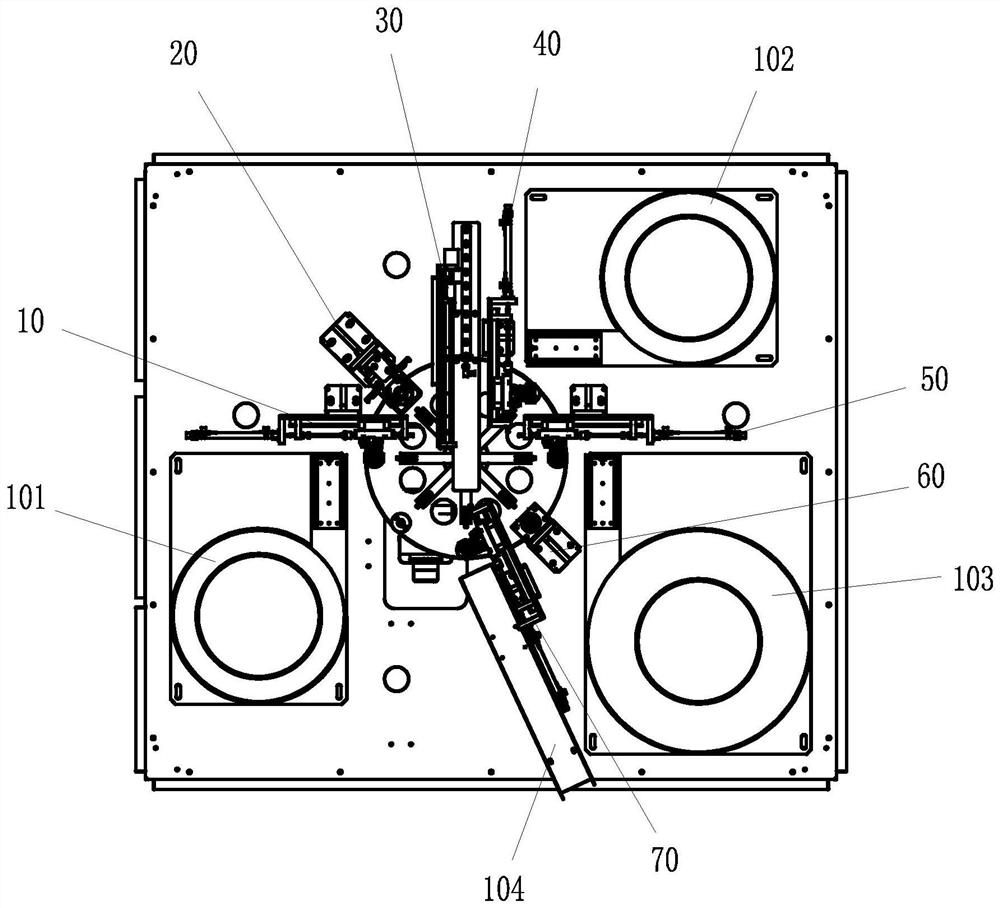

[0034] Please check figure 1 and figure 2 , a magnetic float production equipment, which includes a turntable 100, a bottom cover incoming vibration plate 101, a bottom cover grabbing mechanism 10, a dispensing mechanism 20, a magnet placement mechanism 30, a middle cover incoming material vibrating plate 102, and a middle cover grabbing mechanism The mechanism 40, the top cover incoming vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com