Green tea refining and rolling device

A rolling device and technology of green tea leaves, which are applied in the field of green tea refining and rolling devices, can solve the problems of reducing the quality of tea rolling, incomplete rolling, and different degrees of rolling, so as to avoid the increase of tea powder, improve rolling efficiency, and avoid The effect of overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

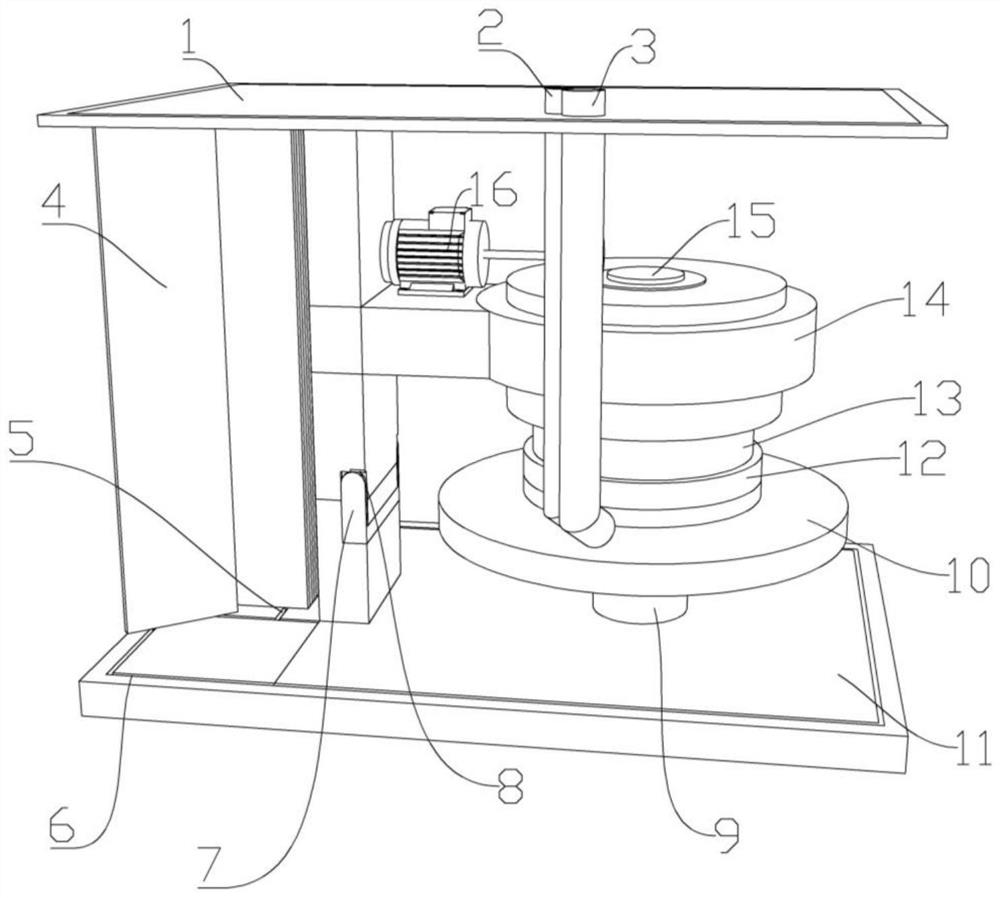

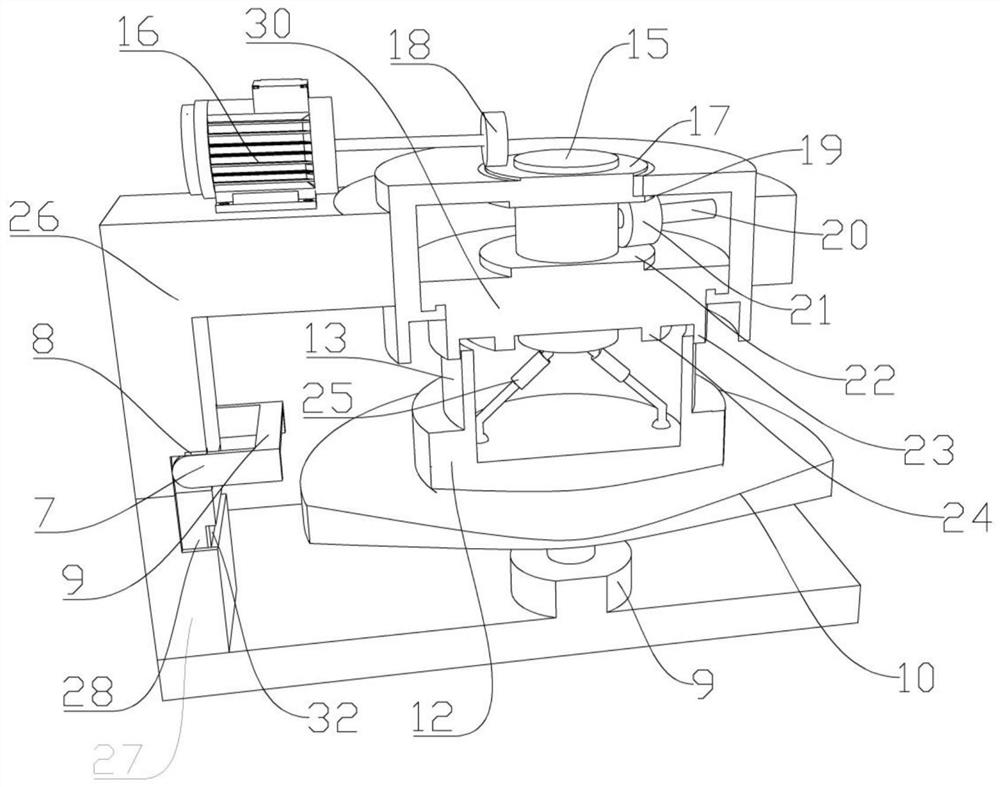

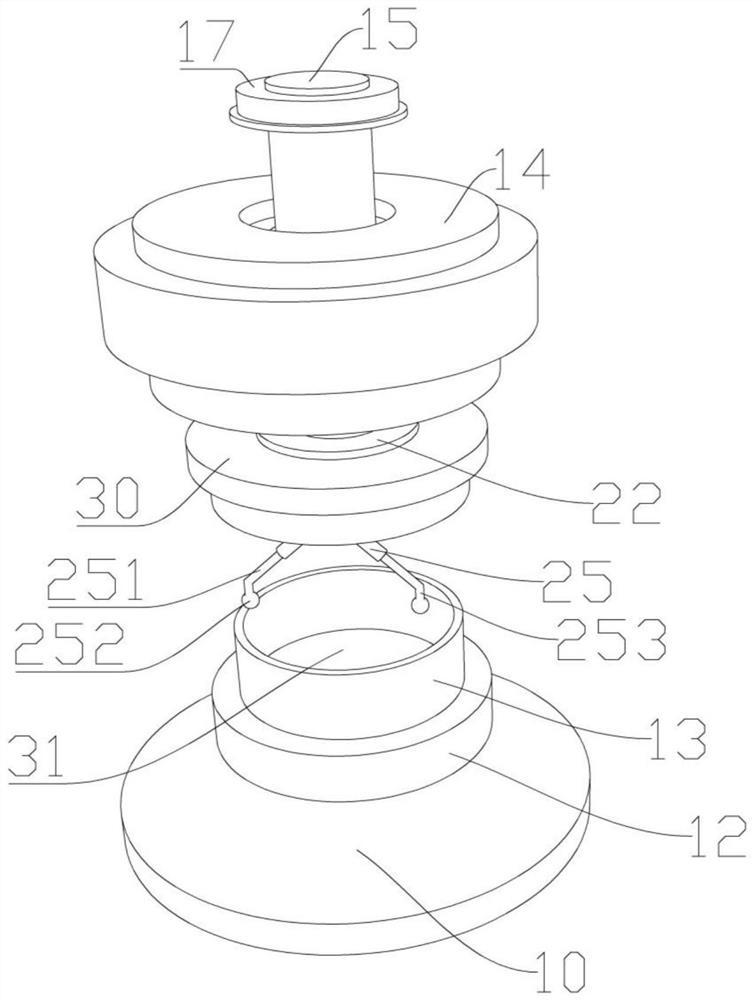

[0035] like Figure 1-4 Shown, a kind of green tea tealeaves refining kneading device comprises base 11, frame, lower kneading plate 10 and upper kneading device, described base 11 top is fixed with telescopic device 9 and frame, and described telescopic device 9 is fixed with lower Kneading disc 10, the upper part of the lower kneading disc 10 is a concave arc surface;

[0036] The upper part of the frame is fixed with a motor 16 and an upper kneading device, and the upper kneading device includes an upper housing 14, and the upper part of the upper housing 14 is provided with a central rotating shaft 15 mounting openings, and the upper housing 14 is provided with a hollow Cavity and annular groove 29, said annular groove 29 is slidably connected with a connecting portion 30, the middle part of said connecting portion 30 is provided with a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com