A chemical reaction kettle

A reaction kettle and chemical technology, applied in the field of chemical reaction kettle, can solve problems such as single direction of action, general mixing effect, and reduced relative speed, and achieve the effect of increasing the swing range, improving the mixing effect, and good liquid-draining effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

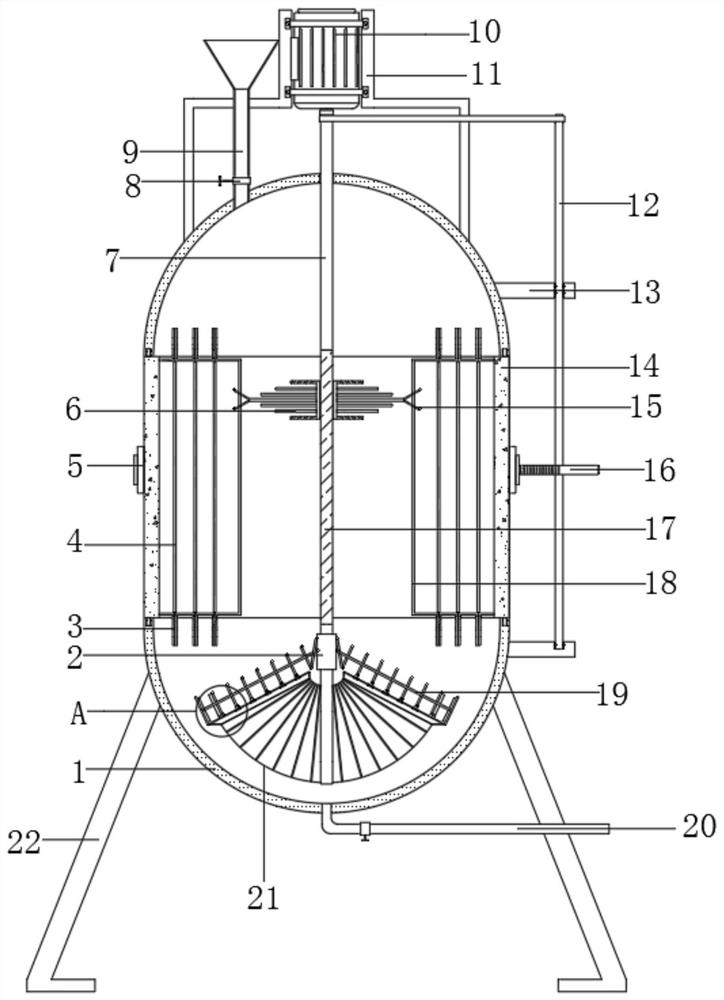

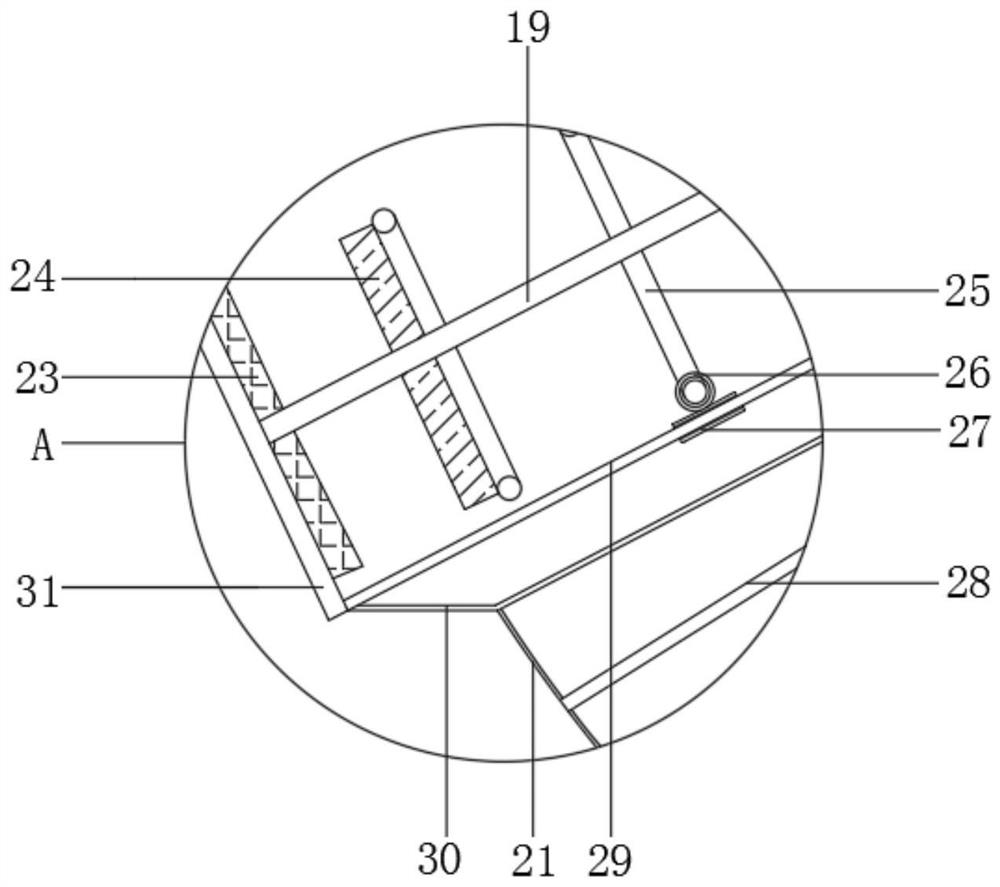

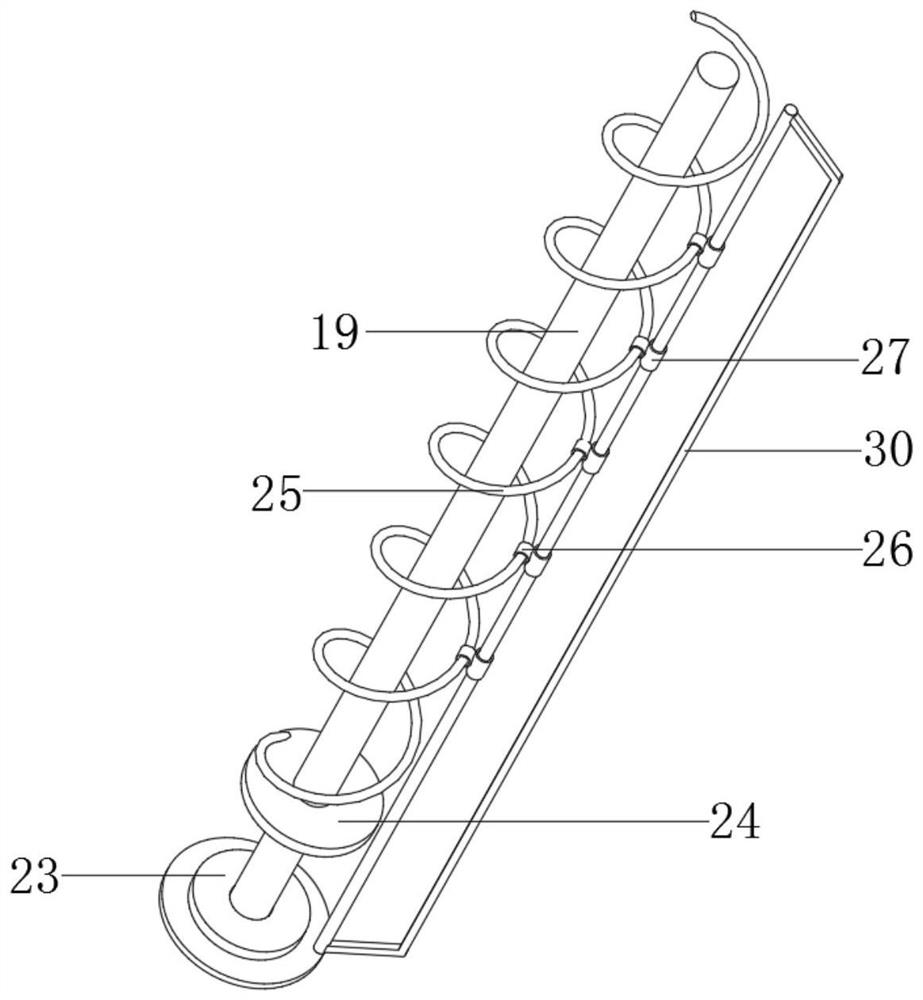

[0031] refer to Figure 1-6 , a reaction kettle for chemical industry, comprising a kettle body 1 with legs 22 welded at the four corners of the outer wall of the bottom, the middle end of the kettle body 1 is rotatably connected with a rotating end 14 through a sealed bearing, and the inner wall of the rotating end 14 is welded with equidistant distribution frame rod 18, and the frame rod 18 is connected to the equidistantly distributed rotating rod 4 through bearing rotation, and the both sides of the end of the rotating rod 4 are connected with the swing paddle 3 through the hinge, and the specifications of the swing paddle 3 on both sides Different, the opposite side of the swing paddle 3 is welded with a vibrating spring 32, one side of the swing paddle 3 is welded with a side wing 33, and the outer wall of the middle end of the rotating rod 4 is welded with a liquid dial 34, and the top of the kettle body 1 is welded There is an installation top frame 11, and the install...

Embodiment 2

[0042] refer to Figure 7 , a reaction kettle for chemical industry. Compared with Embodiment 1, this embodiment also includes that the laminate 6 is fixedly installed with inserts 37 distributed equidistantly, and the two ends of the insert 37 are respectively fixedly equipped with upper half-ring pieces 36 and The lower half-ring sheet 38, the opening direction of the upper half-ring sheet 36 and the lower half-ring sheet 38 are opposite; during the rotation process of the laminate 6 itself, the inserting sheet 37 is used to mix the liquid well in the horizontal direction; and the setting The upper half-ring piece 36 and the lower half-ring piece 38 at both ends of the insertion piece 37 and whose opening directions are opposite, during the rotation process with the insertion piece 37, the upper half-ring piece 36 can play a stirring effect on the liquid, and the lower half-ring piece 36 can move the liquid. Sheet 38 can play the broken flow effect.

[0043] When the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com