A circulating water cleaning device for corroded aluminum foil

A cleaning device and a technology for corroding aluminum foil, which is applied to measuring devices, test water, cleaning methods and utensils, etc., can solve the problems of pure water waste, reduced cleaning effect, and easy contamination of pure water, so as to improve cleaning effect and save water volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

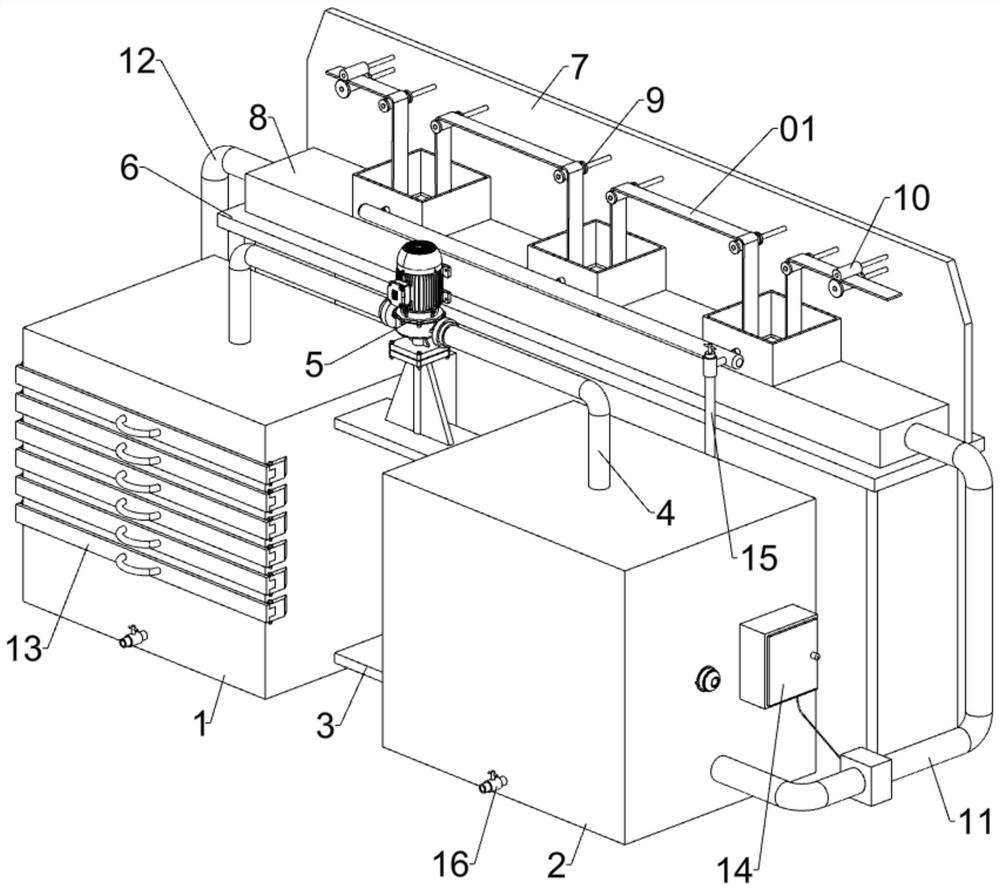

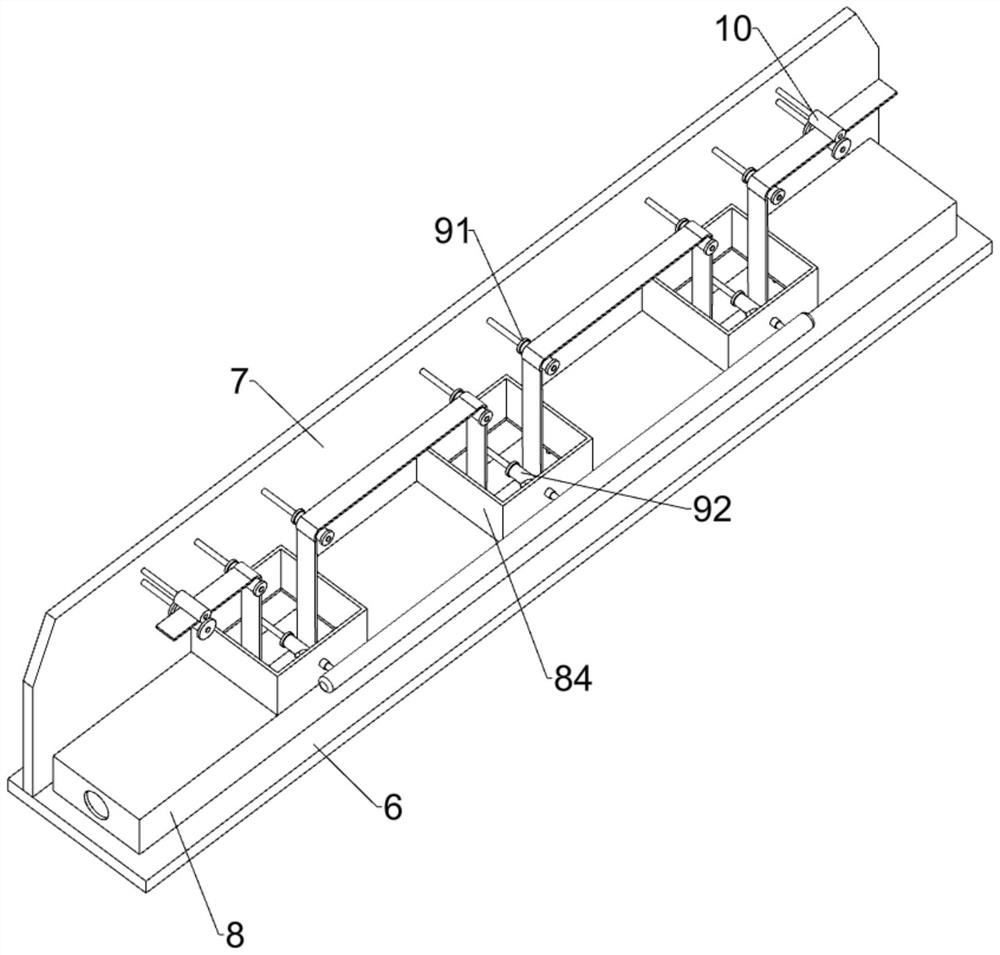

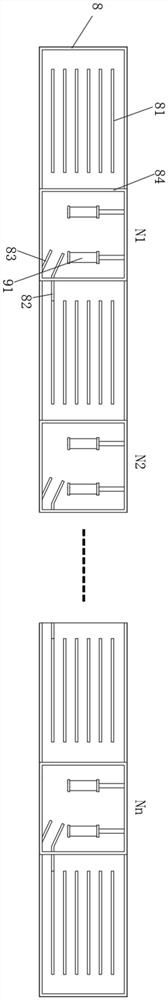

[0031] Such as Figure 1-6 As shown, a corroded aluminum foil circulating water cleaning device includes a filter box 1 and a water storage tank 2 arranged side by side and at the same level and at the same height. There are two upper and lower pieces between the filter box 1 and the water storage tank 2 for connecting the two Connecting plate 3, a first communication pipe 4 is arranged between the filter box 1 and the upper side of the water storage tank 2, one end of the first communication pipe 4 communicates with the filter box 1, and the other end of the first communication pipe 4 communicates with the water storage tank 2 , the middle part of the first communication pipe 4 is provided with a water delivery pump 5, the water delivery pump 5 is fixedly arranged on the upper connecting plate 3, and the side parallel to the filter box 1 and the water storage tank 2 is provided with a bracket 6, and the bracket 6 is far away from the filter Side plate 7 is arranged on the sid...

Embodiment 2

[0040] Such as Figure 7 and Figure 8 As shown, the difference from Embodiment 1 is that it also includes an automatic chloride ion control system 14 for monitoring the chloride ion content in the water filtered by the filter box 1, and the automatic chloride ion control system 14 includes a set on the outer wall of the water storage tank 2 A circuit box 1401, a central control unit 1405 located in the circuit box 1401 and electrically connected to the water delivery pump 5, and a chloride ion detector 1402 arranged on the water outlet pipe 11 for detecting the content of chloride ions, the chloride ion detector 1402 passes through the wire 1403 is electrically connected to the central control unit 1405 . An alarm 1404 is arranged on the outer wall of the water storage tank 2, and the alarm 1404 is electrically connected with the central control unit 1405.

[0041] When the chloride ion content of the pure water coming out of the water storage tank 2 exceeds a predetermined...

Embodiment 3

[0043] Such as Figure 9 As shown, the difference from Embodiment 2 is that it also includes a spraying mechanism 15 for further cleaning the chloride ions on the upper surface of the aluminum foil 01. The nozzle 1501 on the side of the water shield 84 away from the side plate 7, the height of the water outlet of the nozzle 1501 is higher than the upper surface of the aluminum foil 01, and the side of the nozzle 1501 connected to the water port is connected with the second connecting pipe 1502. The pipe 1502 communicates with the bottom of the water storage tank 2 through a conduit 1503, and a water stop valve 1504 is arranged on the conduit 1503.

[0044] In order to further wash away the chloride ion content on the upper surface of the aluminum foil 01, the staff unscrews the water stop valve 1504 so that the pure water in the water storage tank 2 enters the second connecting pipe 1502 through the conduit 1503, and then passes through each nozzle 1501 for cleaning The upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com