Forging equipment capable of automatically clearing debris and applicable to metal processing

An automatic cleaning and metal processing technology, applied in the field of forging, can solve the problems of metal debris splashing everywhere, affecting the normal use of staff, affecting the normal use of forging rods, etc., to achieve a safe working environment and convenient forging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

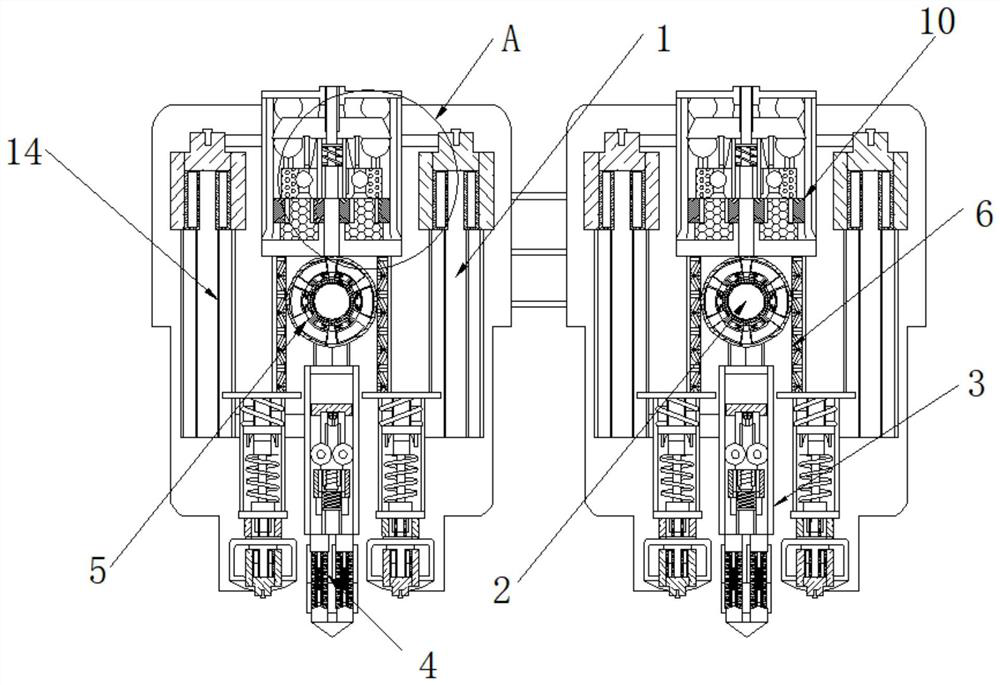

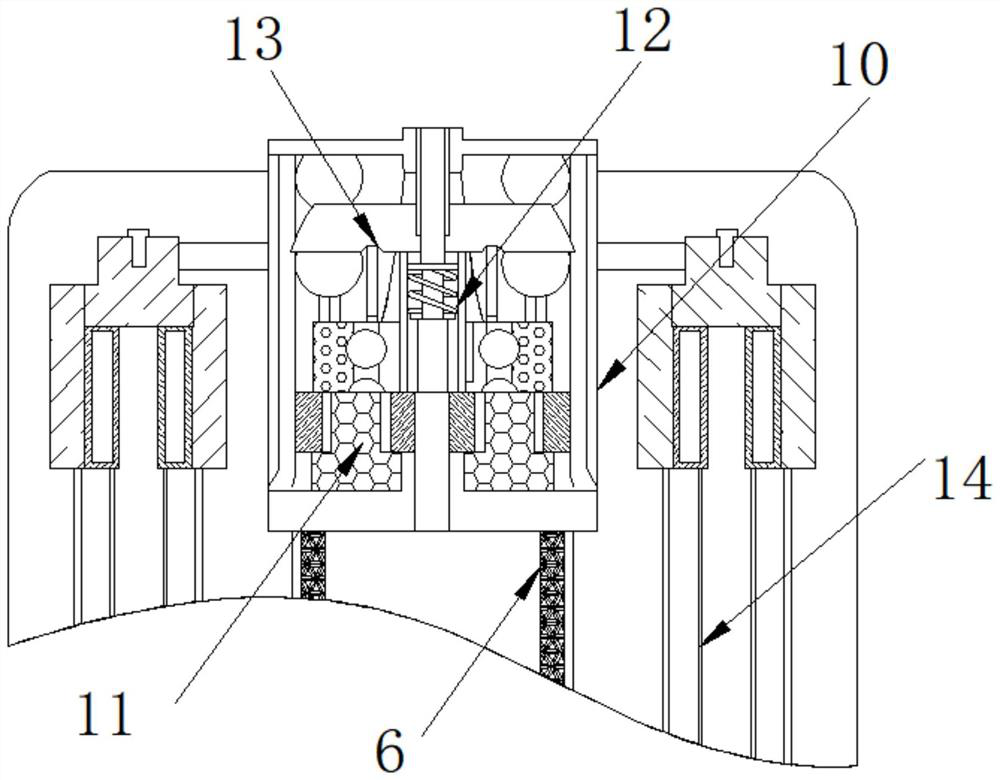

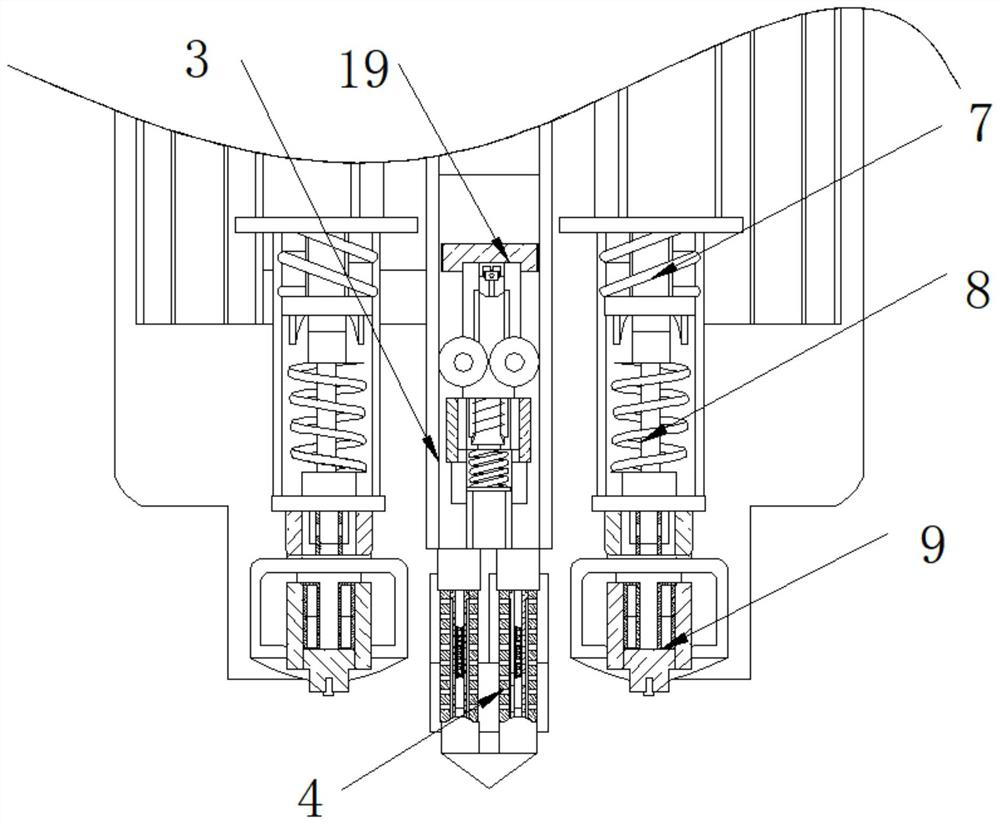

[0020] The present invention will be further described below in conjunction with accompanying drawing:

[0021] as attached figure 1 to attach Figure 5 Shown:

[0022] The present invention provides a forging equipment for metal processing that can automatically clean up debris, comprising a forging seat 1, a movable seat 2 is movably connected to the inside of the forging seat 1, a support seat 3 is movably connected to the side surface of the movable seat 2, and the forging seat 1 The inner rotating connection of the movable seat 2 is connected with a rotating shaft, the diameter of the winding shaft 5 is larger than that of the movable seat 2, the side surface of the holding seat 3 is movably connected with a forged rod 4, and the outer surface of the movable seat 2 is movably connected with a winding Shaft 5, the outer surface of the winding shaft 5 is sleeved with a connecting rope 6, one end of the connecting rope 6 is movably connected with a top holding rod 7, the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com