Building steel cutting machine

A cutting machine and steel technology, applied in the direction of grinding machine parts, grinding machines, grinding/polishing equipment, etc., can solve the problems of rolling accidents of building materials, affecting the operation of workers, and generating a large number of sparks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

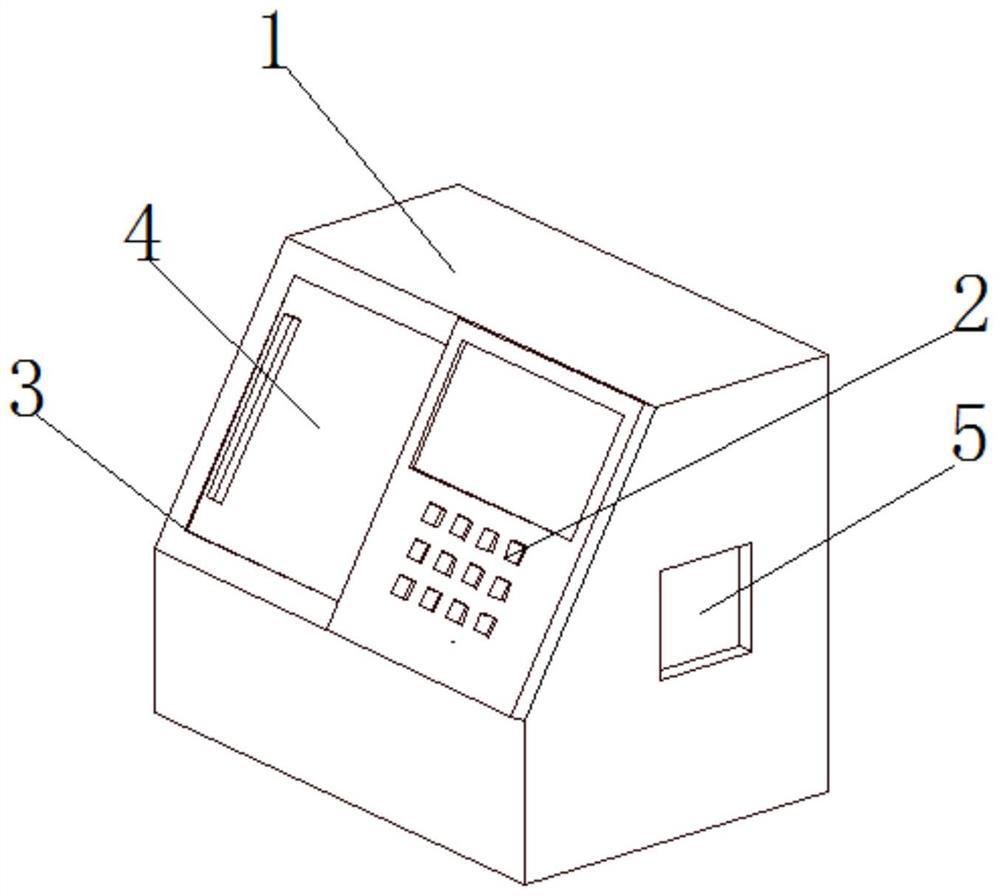

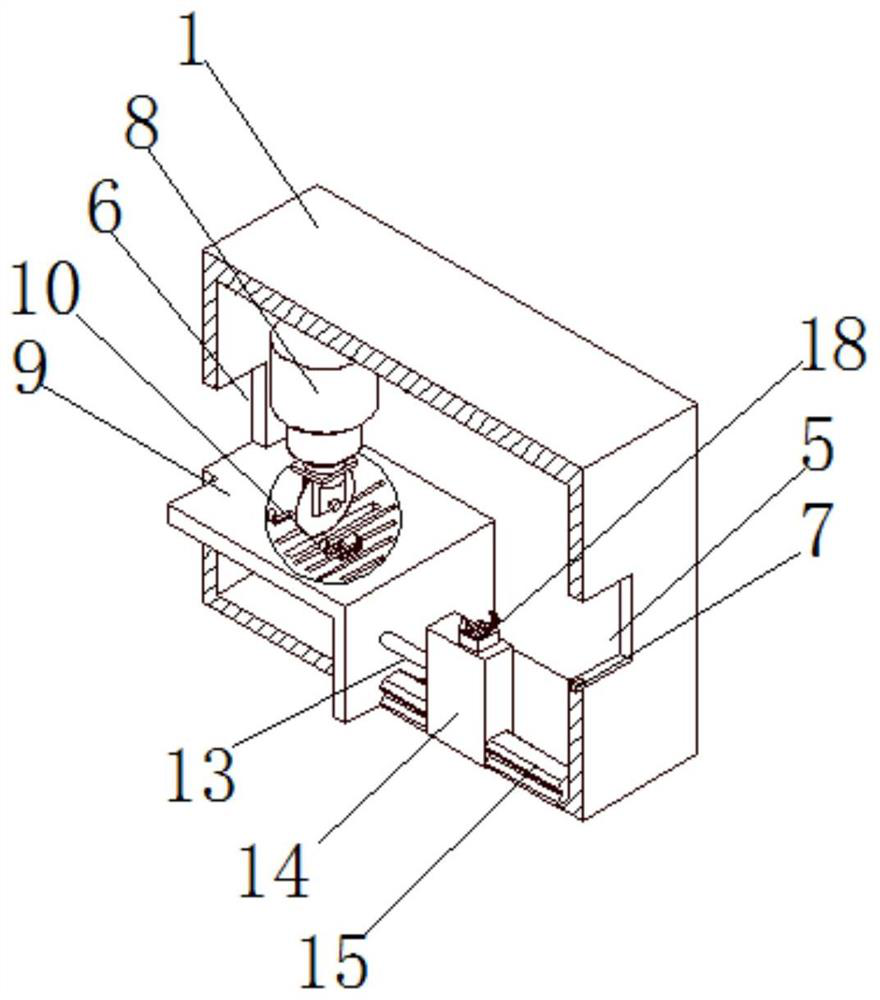

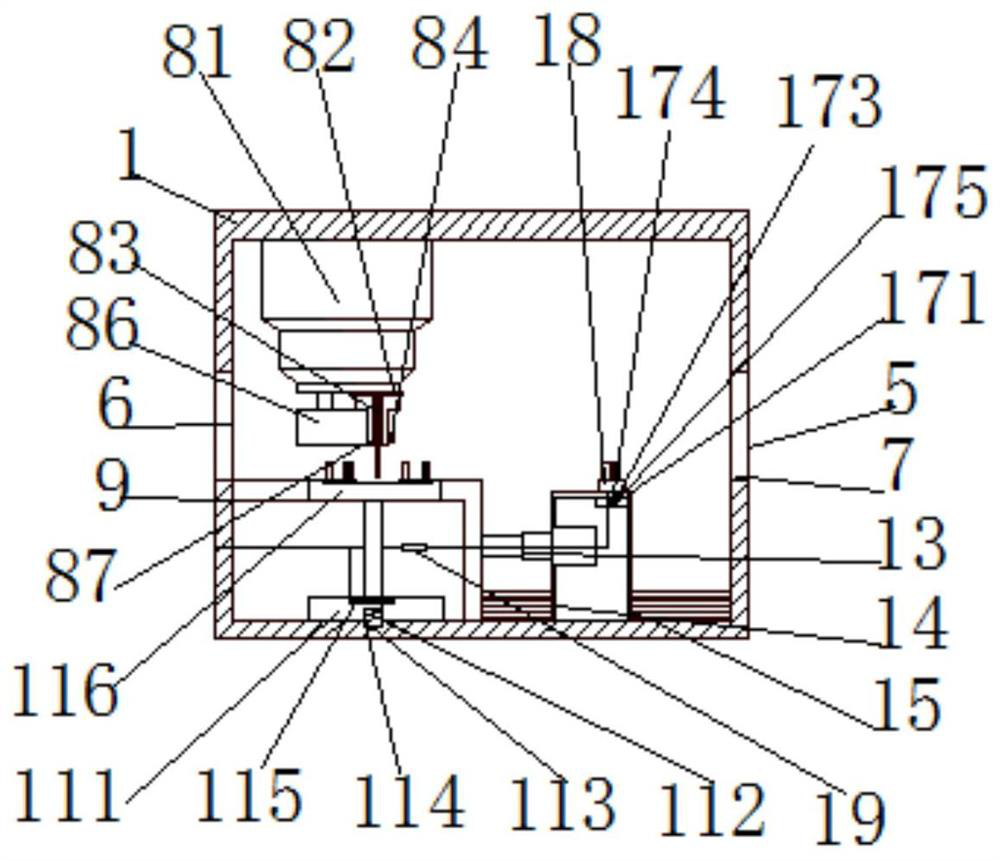

[0035] see Figure 1-3 , the present invention provides a technical solution: a construction steel cutting machine, including a casing 1, a controller 2 is fixedly connected to one side of the casing 1, and a first through slot is opened on the side of the casing 1 close to the controller 2 3. A transparent acrylic plate 4 is slidably connected to one side of the first through groove 3. The first feeding port 5 and the second feeding port 6 are respectively opened on both sides of the casing 1. One side of the first feeding port 6 is provided with a second feeding port. A solenoid valve starts the switch 7, the top of the inner wall of the casing 1 is fixedly connected with a cutting mechanism 8, the bottom of the inner wall of the casing 1 is fixedly connected with a support plate 9, and the top of the support plate 9 is provided with a second through groove 10, the second through groove The inner wall of 10 is rotatably connected with a first rotating mechanism 11, one side ...

Embodiment 2

[0037] see Figure 1-4 On the basis of Embodiment 1, the present invention provides a technical solution: a construction steel cutting machine, the first rotating mechanism 11 includes a first rotating disk 111, and the bottom of the first rotating disk 111 is provided with a first circular groove 112, The top of the inner wall of the first circular groove 112 is rotatably connected with a first fixed rod 113 through a bearing, and the end of the first fixed rod 113 away from the first rotating disk 111 is fixedly connected with a first compression spring 114, and the first compression spring 114 is away from the first fixed rod 113. One end of the rod 113 is fixedly connected with the first rotating disk 111, the inside of the first rotating disk 111 is provided with a first arc-shaped groove 115, and the top of the first rotating disk 111 is fixedly connected with a cutting plate 116 through a connecting rod, and the cutting plate 116 is away from One side of the first rotat...

Embodiment 3

[0039] see Figure 5-7 On the basis of Embodiment 2, the present invention provides a technical solution: a construction steel cutting machine, the clamping mechanism 18 includes a fixed housing 181, and a second motor 182 is fixedly connected to one side of the inner wall of the fixed housing 181, the second The drive shaft of the second motor 182 is fixedly connected with a clamp 183. The clamp 183 includes a clamp shell 1831. One side of the clamp shell 1831 is provided with a fourth through groove 1832. The inside of the clamp shell 1831 is provided with a third arc-shaped groove 1833. One side of the groove 1833 is fixedly connected with an air cushion 1834, and one side of the air cushion 1834 communicates with the air pump 12 through a soft air tube and the second electromagnetic valve 20, and the side of the air cushion 1834 away from the third arc-shaped groove 1832 is fixedly connected with a linkage block 1835, and the linkage One end of the block 1835 away from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com