Storage device for anti-dry glue for shoes

A technology for storage devices and shoes, which is applied to mixers with rotary stirring devices, transportation, packaging, dissolving and other directions, can solve the problems of no glue storage device, waste of glue, etc., to improve the quality of glue, improve the effect of stirring, The effect of improving mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

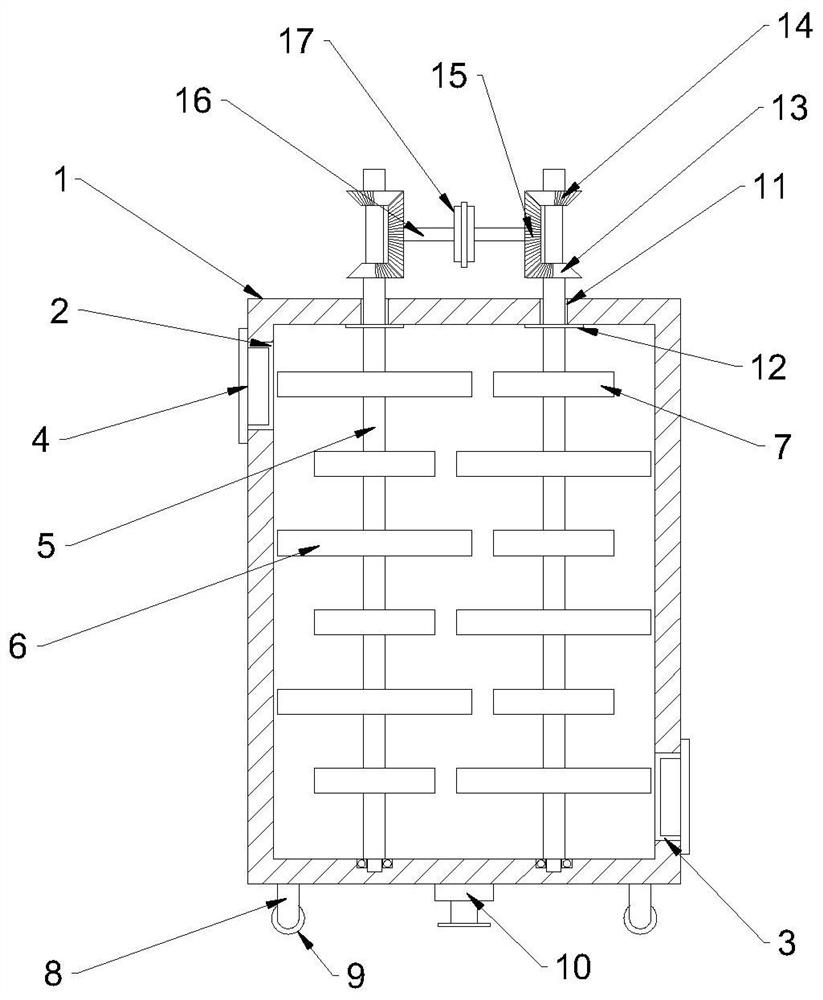

[0018] see figure 1 and figure 2 , an anti-drying glue storage device for shoes, comprising a body 1, a feed port 2, a discharge port 3, a cover plate 4, a stirring shaft 5 and a first blade 6, and a feed port is provided on the left side wall of the body 1 2. The lower part of the right side wall of the main body 1 is provided with a discharge port 3, the cover plate 4 is detachably installed on the feed port 2 and the discharge port 3, and the stirring shaft 5 is arranged inside the main body 1, and the stirring shaft 5 is welded and fixed with a second One blade 6; the quantity of the first blade 6 is greater than one, and the second blade 7 is also welded and fixed on the stirring shaft 5. By interlacing the first blade 6 and the second blade 7, the stirring efficiency can be effectively improved, and at the same time, The technical effect of improving the quality of the glue is reached; the lower end surface of the main body 1 is bolted with a wheel frame 8, and the uni...

Embodiment 2

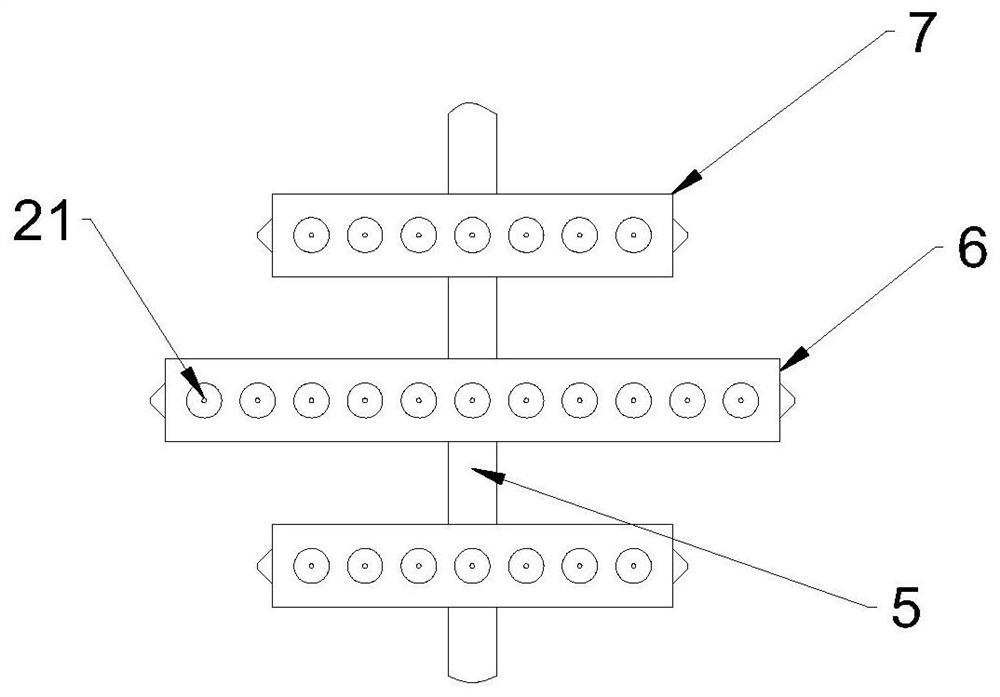

[0020] see image 3 The second blade 7 is 2-4cm shorter than the first blade 6, and the first blade 6 and the second blade 7 are welded and fixed with stirring teeth 21, which can further improve the stirring effect of the device.

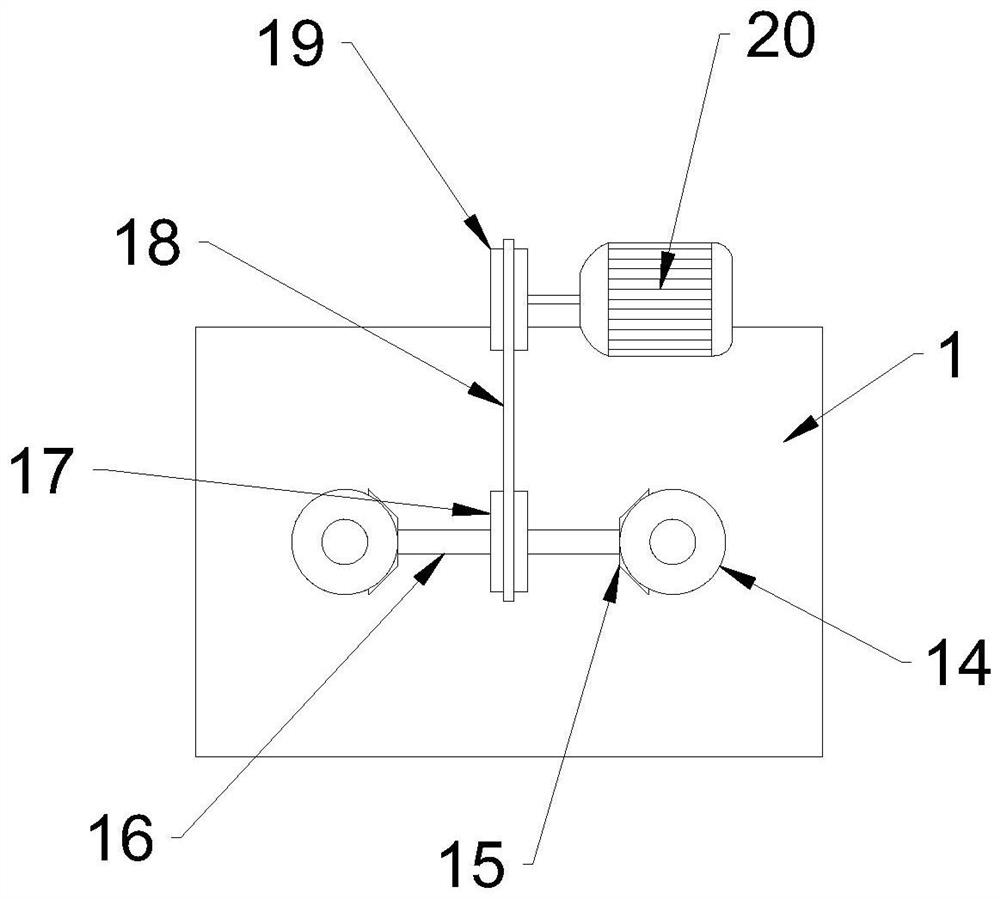

[0021] The working principle of the present invention is: during the stirring process, glue is loaded into the feed port 2, then the feed port 2 is sealed by the cover plate 4, and then the motor 20 is started, and the motor 20 sequentially drives the driving pulley 19, the transmission pulley 17, the transmission The shaft 16 and the transmission bevel gear 15 rotate, and the rotation of the transmission bevel gear 15 makes the driving half bevel gear 13 and the driven half bevel gear 14 rotate sequentially, which drives the stirring shaft 5 to reciprocate, which greatly improves the stirring effect. A first blade 6 and a second blade 7 with different lengths are welded and fixed on the shaft 5, and stirring teeth 21 are also welded and fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com