Large-scale motor rotor shaft turning-over hoisting tool

A technology of large motors and lifting tools, which is applied in the direction of load hanging components, transportation and packaging, etc. It can solve the problems of motors not working normally without any protection and protection measures, affecting motor assembly, etc., to achieve high hoisting efficiency and structure Simplicity and effect of equipment cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

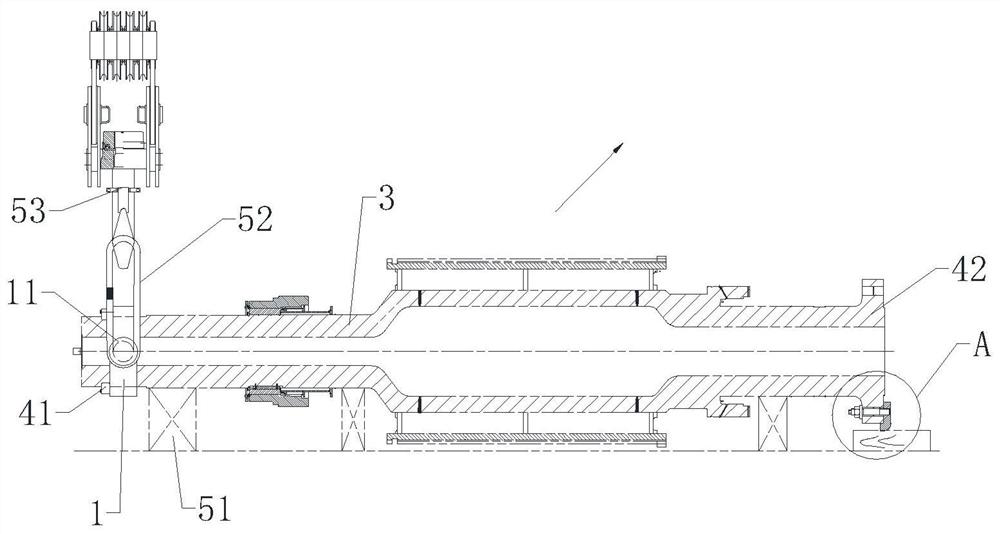

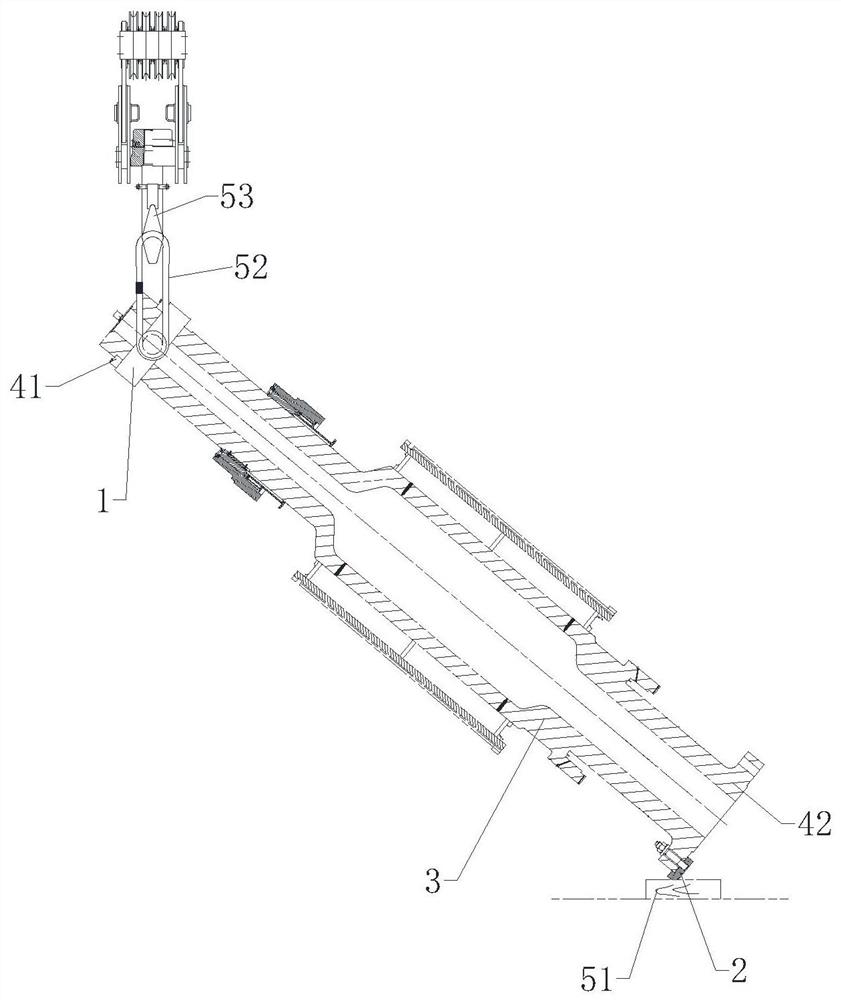

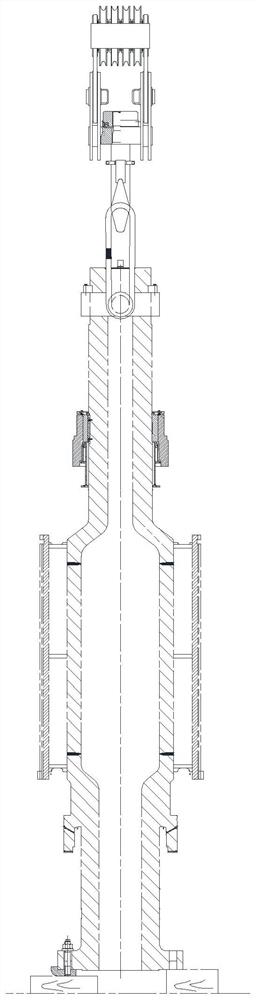

[0024] like Figure 1-7 As shown, the lifting tool for turning over the rotor shaft of a large motor includes a snap ring 1 installed on the neck of the rotor shaft 3 and a turning shoe 2 installed on the grounding side of the bottom end of the rotor shaft 3. The neck of the rotor shaft 3 is provided with a first flange 41 The bottom end of the rotor shaft 3 is provided with a second flange 42, the outer peripheral surface of the snap ring 1 is symmetrically provided with lifting lugs 11, and the top surface of the snap ring 1 is connected with the first flange 41; The bottom surface of the two flanges 42 is connected to the plane part 21, and the bottom end of the plane part 21 is provided with a bent part 22 covering the outer arc surface of the second flange 42, and the bent part 22 is in contact with the outer arc surface of the second flange. Matching, the inward bend between the bent part 22 and the flat part 21 is a right-angle transition area 23 that fits the corner of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap