Gantry crane prefabricated foundation and mounting method thereof

A gantry crane and foundation technology, which is applied in basic structure engineering, transportation and packaging, load hanging components, etc., can solve the problems of many processes, the in-situ foundation cannot be reused, and the construction period of the in-situ foundation is long. The effect of saving time in pouring-in-place and curing cycles and reducing foundation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

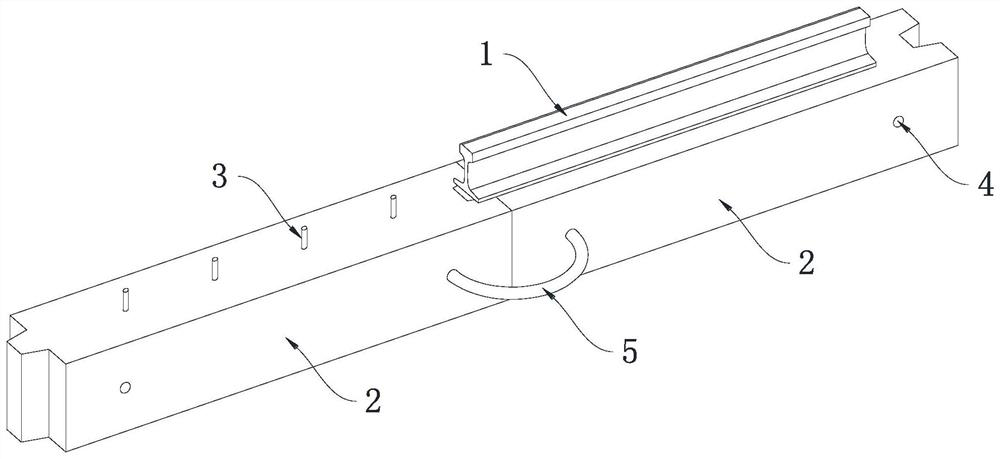

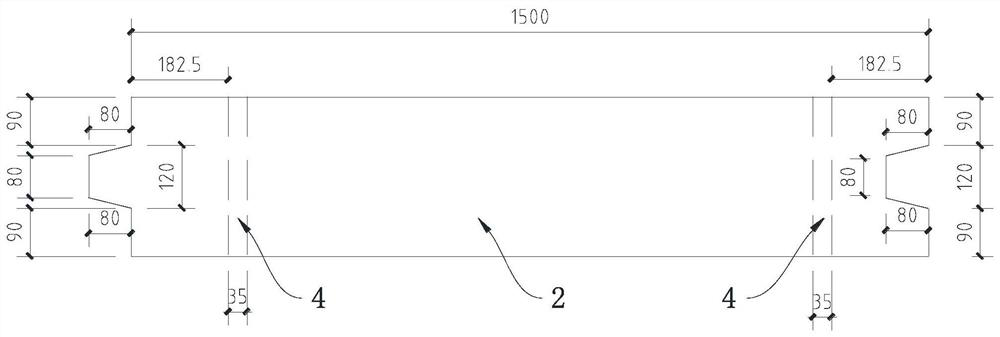

[0026] Such as figure 1 As shown, the present invention includes a gantry crane prefabricated foundation, including a track 1 and a strip-shaped prefabricated foundation. The prefabricated foundation is formed by at least two prefabricated sections 2 spliced in series, and the series splicing refers to the end-to-end splicing of the two ends of the prefabricated section 2 , in series. The prefabricated section 2 is a reinforced concrete structure, the top of the precast section 2 is flat, and the connecting rib 3 is buried in the precast section 2, and the connecting rib 2 is buried in the reinforced concrete of the precast section 2, and the connecting rib 2 can be connected with the structure of the precast section 2 Or not connected, one end of the connecting rib 3 passes through the top surface of the prefabricated section 2. There are multiple connecting ribs 3, pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com