A kind of trapezoidal silicone resin reinforced silicone pressure-sensitive adhesive and preparation method thereof

A technology of silicone pressure-sensitive adhesive and silicone resin, which is applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., and can solve the problem of poor uniformity, compatibility and dispersion of MQ silicone resin dispersion reinforcement effect and other problems, to achieve the effect of improving product transparency, improving reinforcement effect, and good reaction specificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

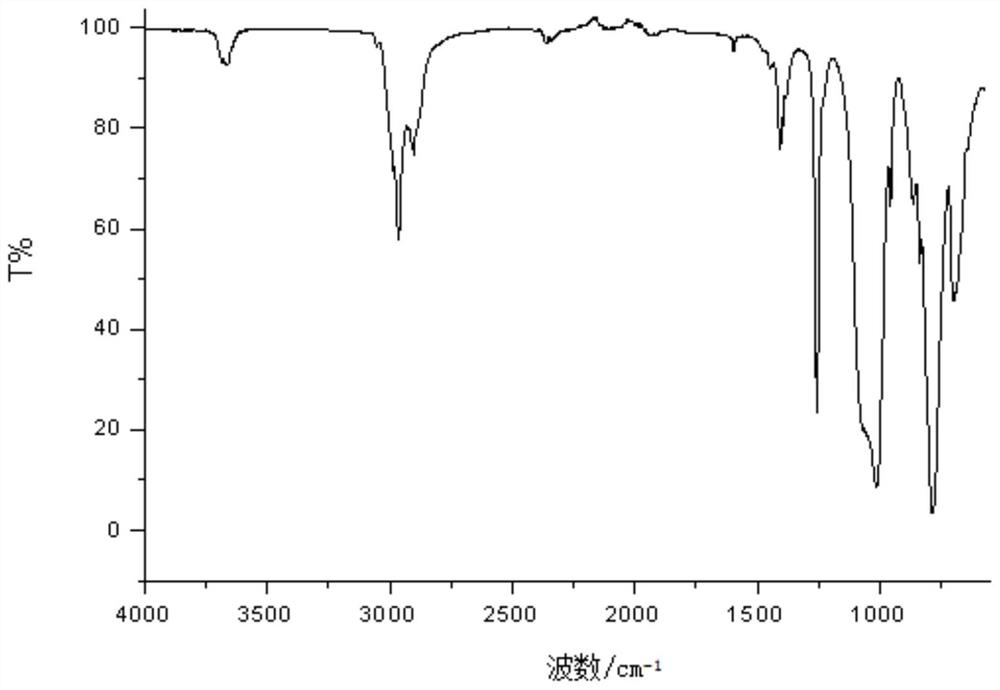

Embodiment 1

[0054] A trapezoidal silicone resin-reinforced silicone pressure-sensitive adhesive of the present embodiment consists of the following components in parts by weight:

[0055] 100 parts of methyl vinyl silicone rubber (number average molecular weight of 500,000, vinyl content of 0.75%), 100 parts of MQ silicone resin (molecular weight of 3000 to 4000, M / Q=0.75 to 0.8), 10 parts of trapezoidal reinforced silicone resin , 10 parts of hydrogen-containing silicone oil (viscosity is 50mPa s, hydrogen content is 0.3%), 1 part of inhibitor silylated alkynol, platinum catalyst 1,3-divinyl-1,1,3,3-tetramethyl Disiloxane platinum (0), (10 ppm in terms of platinum content), 200 parts of dilution solvent toluene.

[0056] The trapezoidal reinforced silicone resin is prepared by the following method:

[0057] (1) Preparation of Methylpolysiloxane Ladder Prepolymer:

[0058] In a four-necked flask equipped with a constant-pressure dropping funnel, a reflux condenser, a thermometer and an ...

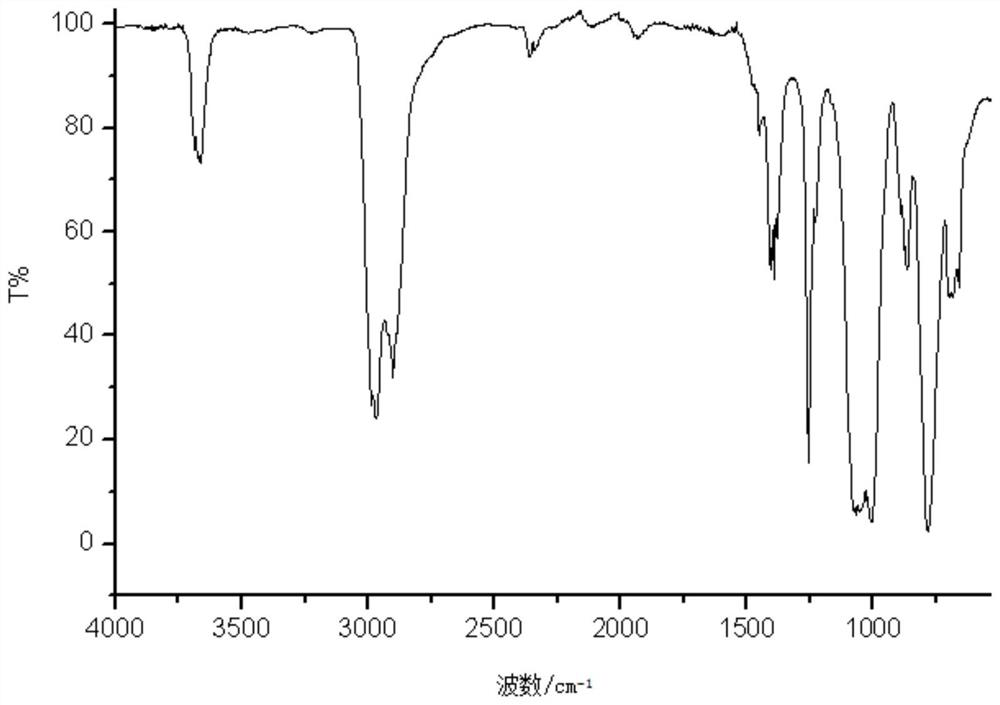

Embodiment 2

[0077] A trapezoidal silicone resin-reinforced silicone pressure-sensitive adhesive of the present embodiment consists of the following components in parts by weight:

[0078] 100 parts of hydroxyl terminated silicone rubber (average molecular weight 600,000), 100 parts of MQ silicone resin (molecular weight 3000-4000, M / Q=0.75-0.8), 10 parts of trapezoidal reinforced silicone resin, 1.6 parts of organic peroxide catalyst BOP, 200 parts of dilution solvent toluene.

[0079] The trapezoidal reinforced silicone resin is prepared by the following method:

[0080] (1) Preparation of Methylpolysiloxane Ladder Prepolymer:

[0081] In a four-necked flask equipped with a constant-pressure dropping funnel, a reflux condenser, a thermometer and an electric mixer, add vinyl-terminated tetramethyldisiloxane (vinyl double-capped head, a=0, M n =186)) and isopropanol solvent, stirring and dissolving evenly, heating and warming up to 80 ℃ under nitrogen protection, adding the chloroplatini...

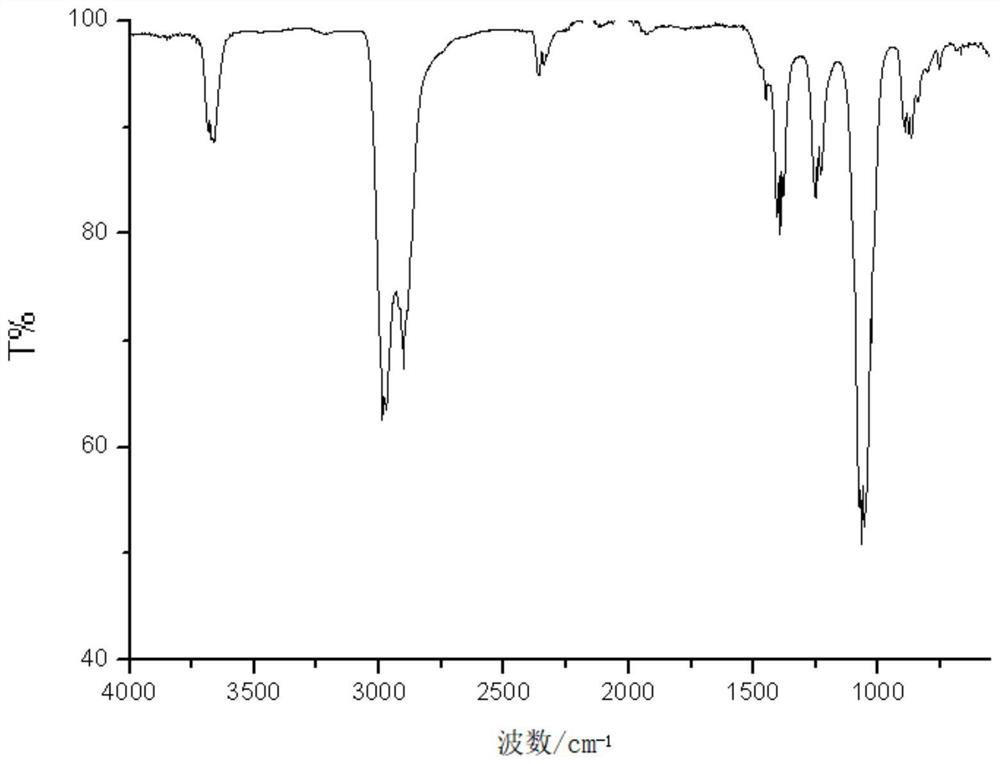

Embodiment 3

[0090] A trapezoidal silicone resin-reinforced silicone pressure-sensitive adhesive of the present embodiment consists of the following components in parts by weight:

[0091] 100 parts of hydroxyl terminated silicone rubber (average molecular weight 600,000), 100 parts of MQ silicone resin (molecular weight 3000-4000, M / Q=0.75-0.8), 10 parts of trapezoidal reinforced silicone resin, 1.6 parts of organic peroxide catalyst BOP, 200 parts of dilution solvent toluene.

[0092] The trapezoidal reinforced silicone resin is prepared by the following method:

[0093] (1) Preparation of Methylpolysiloxane Ladder Prepolymer:

[0094] In a four-necked flask equipped with a constant-pressure dropping funnel, a reflux condenser, a thermometer and an electric mixer, add vinyl-terminated polydimethylsiloxane (a=8, average molecular weight M n 800) and ethylene glycol monoethyl ether solvent, stir and dissolve evenly, heat up to 80°C under nitrogen protection, add the calculated amount of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com