Alloy copper pipe annealing device and alloy copper pipe annealing treatment method

A copper tube and annealing technology, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problem of inability to detect the effectiveness of coiled copper tube purging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

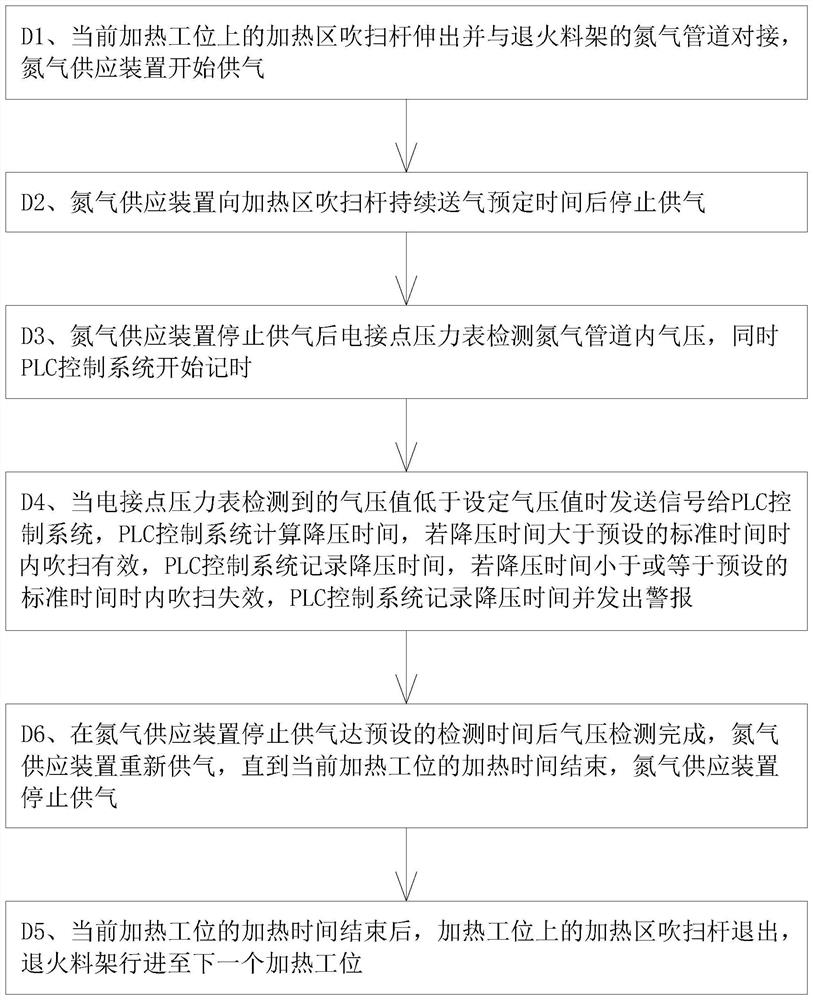

[0034] This embodiment provides an alloy copper tube annealing device, including an annealing furnace, stacker, annealing rack, vacuum device, nitrogen supply device and PLC control system, and the annealing furnace is provided with a vacuum chamber, a transition zone, and a heating zone and cooling zone, the annealing furnace is equipped with conveying roller table and heating device, the annealing material frame moves in the annealing furnace along the conveying roller table, and the annealing material frame is provided with a number of accommodation positions for placing coiled copper pipes, each Nitrogen pipelines are provided on the storage positions, and the feature is that: there are several heating stations in the heating zone, each heating station is equipped with a heating zone purge rod, and the gas inlet of the heating zone purge rod is connected to the nitrogen supply. The device is connected, the gas outlet of the purge rod in the heating area is set opposite to t...

Embodiment 2

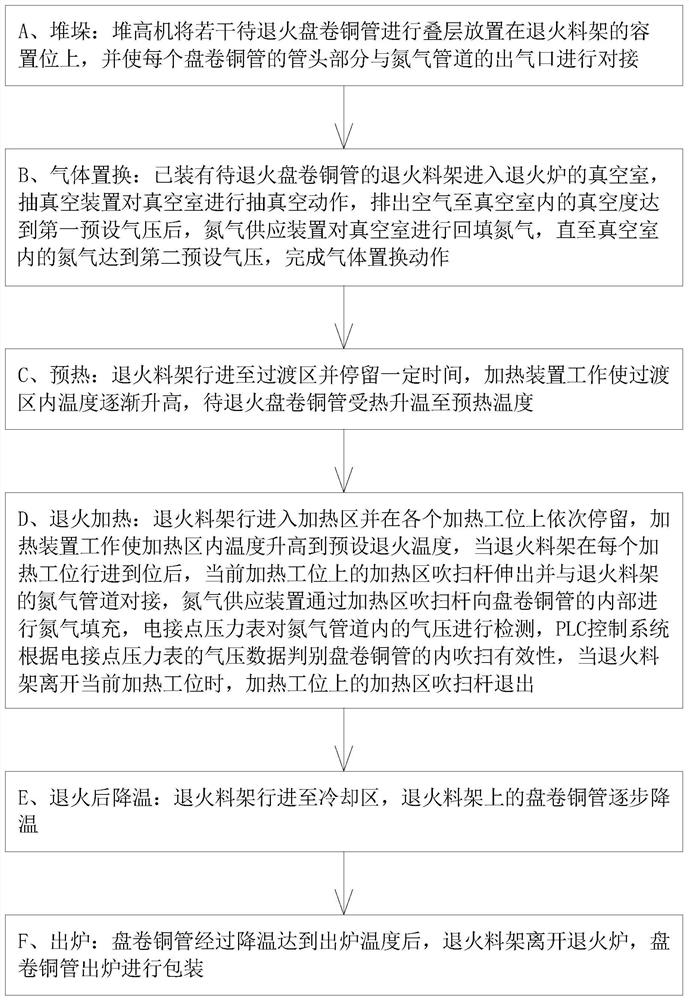

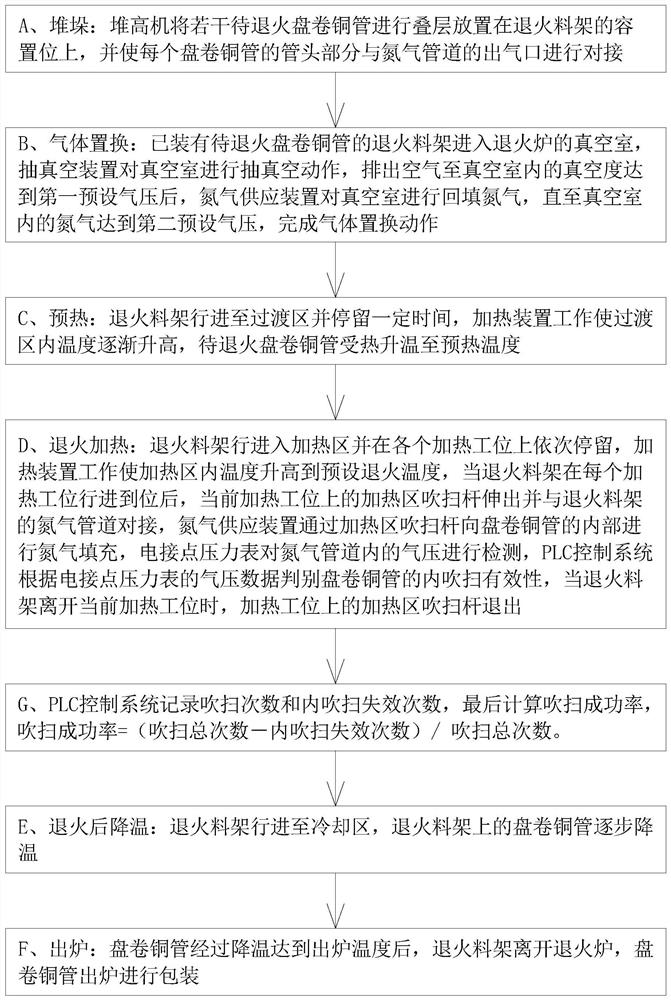

[0039] Such as figure 1 As shown, what this embodiment provides is a method for annealing an alloy copper tube, which is characterized in that it includes the following steps:

[0040] A. Stacking: The stacker stacks a number of coiled copper tubes to be annealed and places them on the storage position of the annealing rack, and makes the tube head of each coiled copper tube dock with the gas outlet of the nitrogen pipeline ;

[0041] B. Gas replacement: the annealing material rack equipped with coiled copper tubes to be annealed enters the vacuum chamber of the annealing furnace, and the vacuuming device performs vacuuming action on the vacuum chamber, and the air is exhausted until the vacuum degree in the vacuum chamber reaches the first preset air pressure , the nitrogen supply device backfills the vacuum chamber with nitrogen until the nitrogen in the vacuum chamber reaches the second preset pressure to complete the gas replacement action;

[0042] In this embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com