Pearlescent printing material and method for preparing pearlescent printing material

A technology of printing materials and pearlescent pigments, which is applied in the direction of copying/marking methods, printing, paper coating, etc., and can solve the problems that pearlescent printing materials need to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

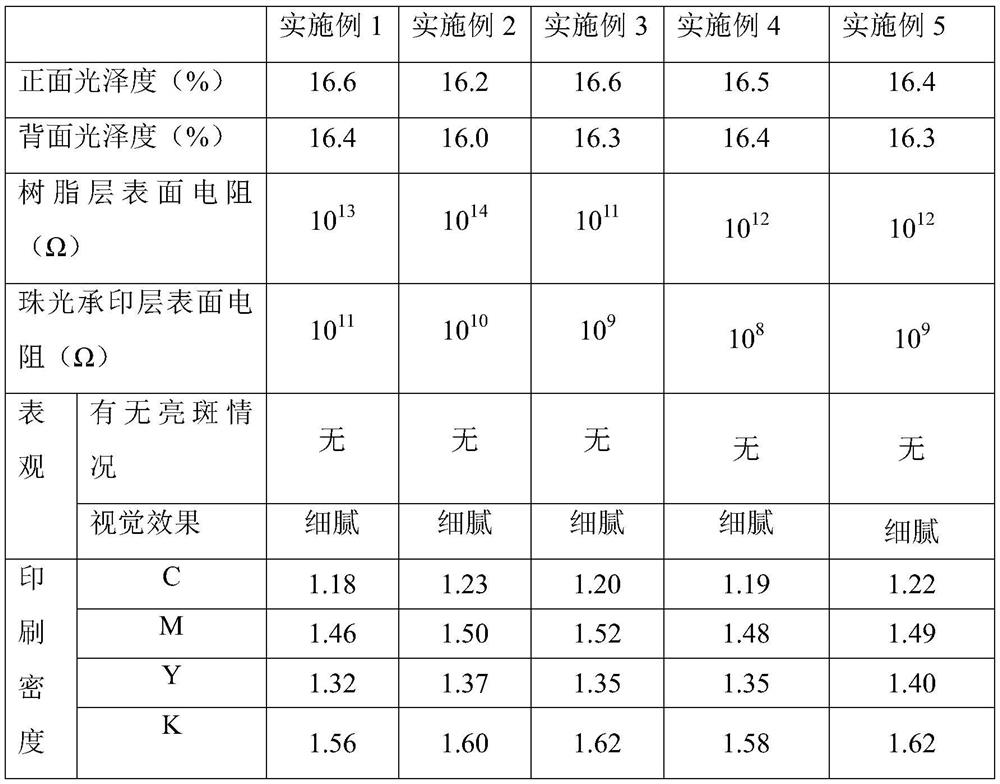

Embodiment 1

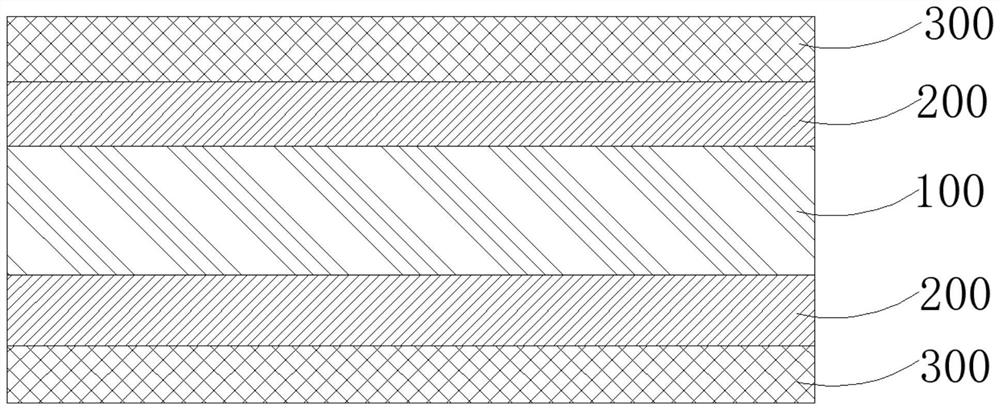

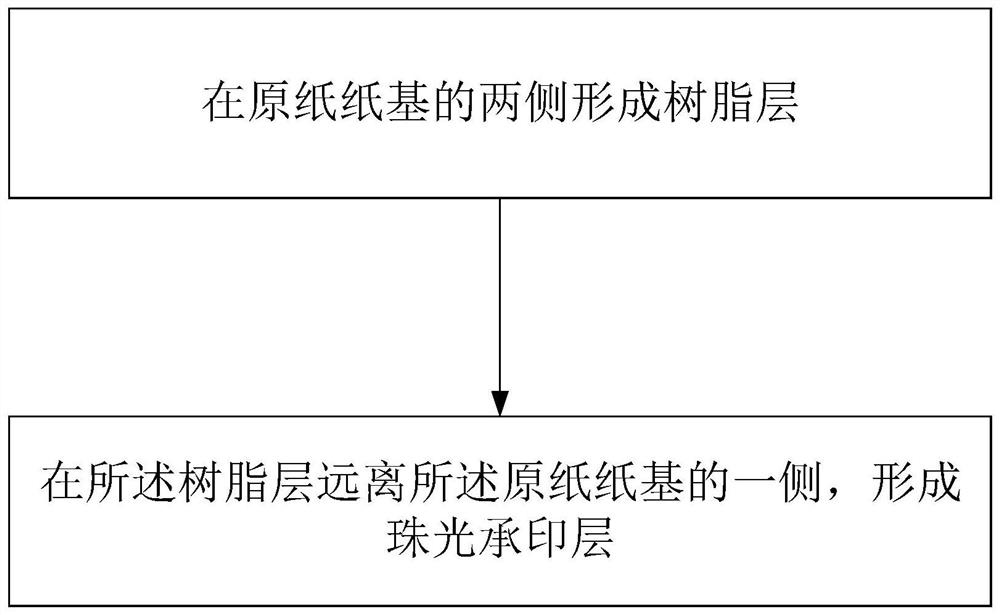

[0046] (1) Mix 70g PE and 0.1g polyether ester amide evenly, melt the particles, extrude with a single-screw screw extruder, and cold roll cold press to form resin layers on both sides of the base paper base. By controlling the temperature of the cold roll The degree of concavo-convexity is such that the surface roughness Ra of the obtained resin layer is 0.5.

[0047] (2) 15g of pearlescent pigments with a particle size of 5 microns, 15g of ethanol, 5g of surfactant, 5g of quaternary ammonium base acrylic acid copolymer emulsion, and 40g of polyvinyl alcohol solution (mass fraction is 10%) are added to the container and stirred evenly , to prepare pearlescent coating solution. Apply the above-mentioned pearlescent coating solution to the side of the resin layer obtained in step (1) away from the base paper base using a coating bar, and dry at a temperature of 100° C. for 3 minutes to obtain a pearlescent printing material.

Embodiment 2

[0049] (1) Mix 90g PP and 5g methyl methacrylate evenly, melt the particles, extrude with a single-screw extruder, and cold roll cold press to form resin layers on both sides of the base paper base. By controlling the temperature of the cold roll The degree of unevenness was such that the surface roughness Ra of the obtained resin layer was 2.0.

[0050] (2) 5g of pearlescent pigments with a particle size of 60 microns, 25g of ethanol, 3g of surfactant, 7g of polyvinylbenzyltrimethylammonium, and 20g of hydroxyethyl cellulose solution (mass fraction is 10%) are added to the container and stirred Evenly, prepare pearlescent coating solution. Apply the above-mentioned pearlescent coating solution to the side of the resin layer obtained in step (1) away from the base paper base using a coating bar, and dry at a temperature of 100° C. for 3 minutes to obtain a pearlescent printing material.

Embodiment 3

[0052] (1) Mix 98g PVA, 1g polyether amide imide and 2g polypyrrole evenly, melt, extrude from a single-bar screw extruder, cold roll cold press, form a resin layer on both sides of the base paper base respectively, pass The concavo-convex degree of the cold roll was controlled so that the surface roughness Ra of the obtained resin layer was 3.0.

[0053] (2) 25g of pearlescent pigments with a particle size of 30 microns, 35g of ethanol, 0.5g of surfactant, 2g of aminoalkyl polyglycol ether, 8g of polyvinylbenzyltrimethylammonium, and 60g of acrylic acid copolymer emulsion are added to the container in sequence Stir evenly in medium to prepare pearlescent coating solution. Use a coating rod to apply the above-mentioned pearlescent coating solution on the side of the resin layer obtained in step (1) away from the base paper base, and dry at a temperature of 100° C. for 3 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com