Percussion drill cast-in-place pile construction device and construction method thereof

A construction device and cast-in-place pile technology, applied in percussion drilling, drilling equipment and methods, sheet pile walls, etc., can solve pile hole inclination, affect pile foundation construction quality, and cannot continuously monitor the deflection state of casing, etc. problem, to achieve the effect of reducing convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

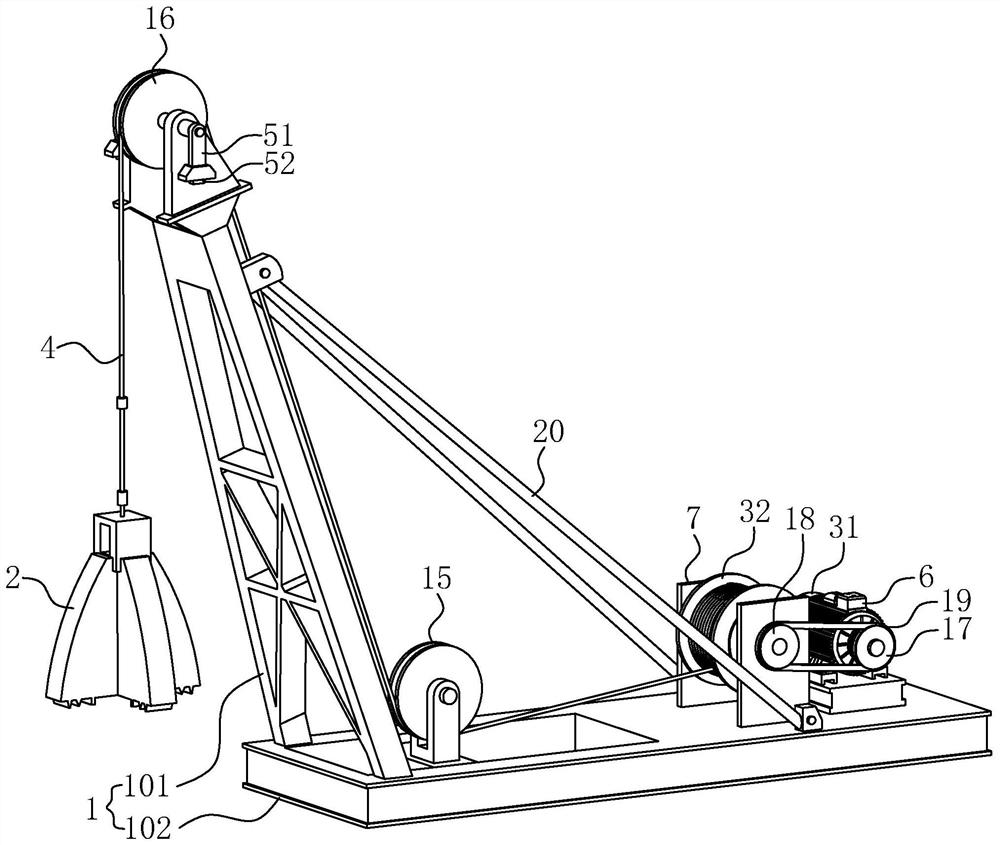

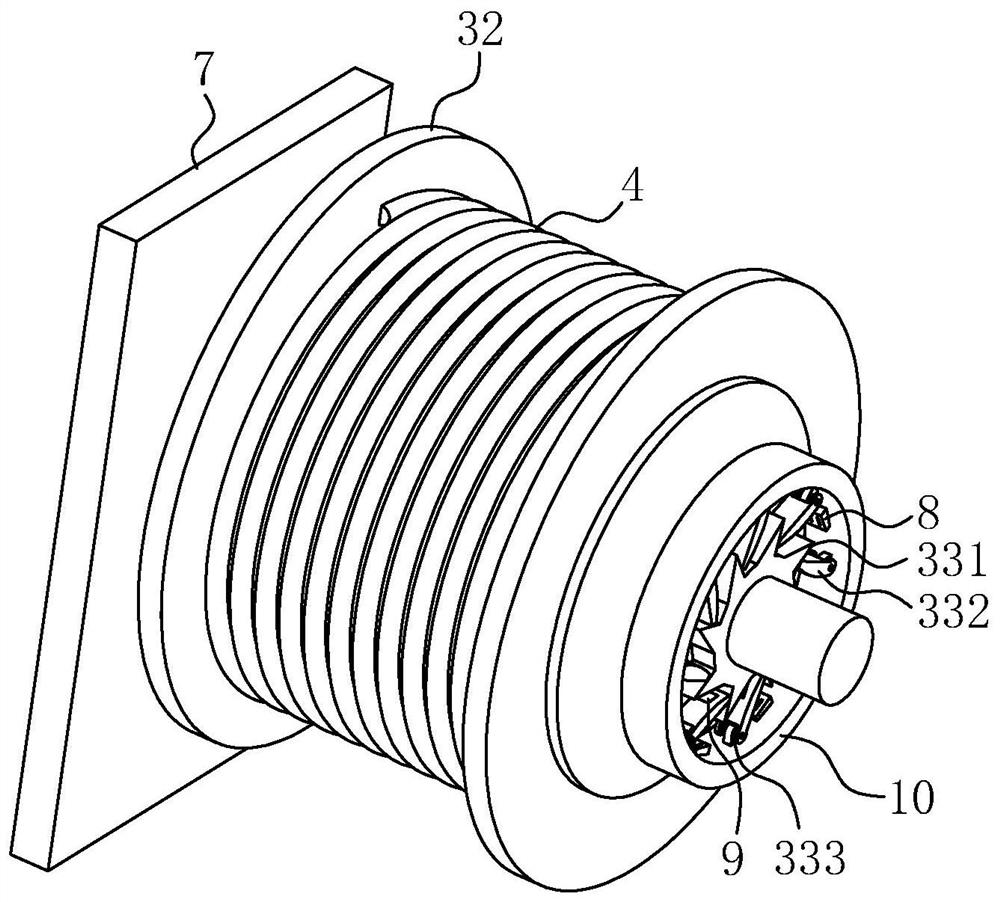

[0047] refer to figure 1 with figure 2 , a percussion drilling cast-in-situ pile construction device, comprising a frame 1, a drill hammer 2, a driving mechanism and a pull rope 4, wherein the frame 1 includes a base 101 and a support 102, and the bottom end of the support 102 is welded and fixed on the base 101, and the angle between the support 102 and the base 101 is an obtuse angle. Two connecting rods 20 are welded and fixed between the upper part of the support 102 and the base 101, so that a triangle is formed between the base 101, the support 102 and the connecting rods 20, so that the structure of the frame 1 is more stable. In other applications, the bottom end of the support 102 is rotatably connected to the base 101, and the upper part of the support 102 is rotatably connected to a connecting rod 20, and the end of the connecting rod 20 away from the support 102 can be fixed on the base 101 by bolts; When installing the frame 1, the free end of the support 102 c...

Embodiment 2

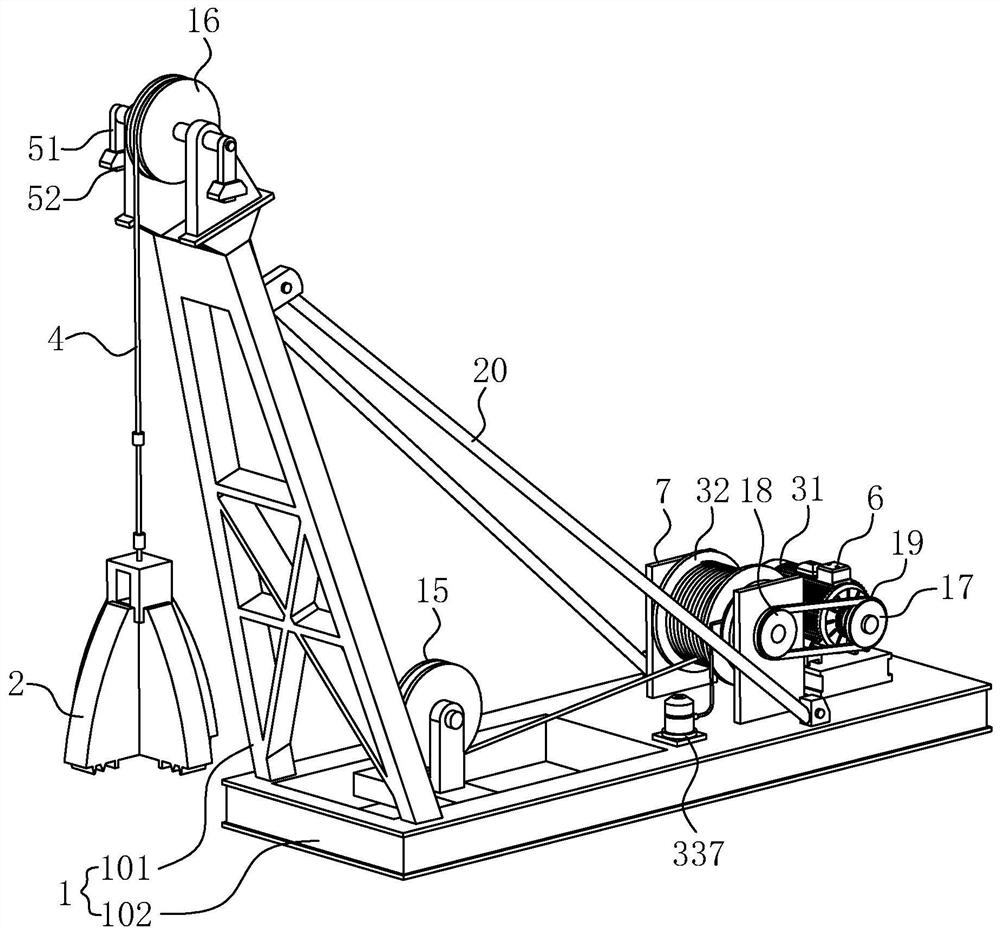

[0056] refer to image 3 with Figure 4 , The difference between this embodiment and Embodiment 1 is that the blocking assembly includes a gear 334, a blocking bar 335, an air bag 336 and an air pump 337, and the side of the support frame 7 is welded with a guide ring 11 and a restricting ring 12, and the restricting ring 12 Located outside the guide ring 11, wherein the air bag 336 is annular, and the air bag 336 is located between the guide ring 11 and the restriction ring 12, that is, the restriction cavity for the air bag 336 is formed between the guide ring 11, the restriction ring 12 and the support frame 7. The air pump 337 is fixed on the base 101 by bolts, the air outlet of the air pump 337 communicates with the air bag 336 through a hose, and the air bag 336 can be inflated and deflated by the air pump 337 .

[0057] The gear 334 is fixed on the rotating shaft of the reel 32 by bolts. The guide ring 11 is provided with a plurality of sliding holes 13 , and the plura...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com