Supporting device for foundation pit construction

A technology for supporting devices and foundation pits, which is used in infrastructure engineering, excavation, construction, etc., can solve the problems of reduced practicability, low supporting strength, and reduced practicability of supporting devices, so as to prevent inward collapse and increase stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

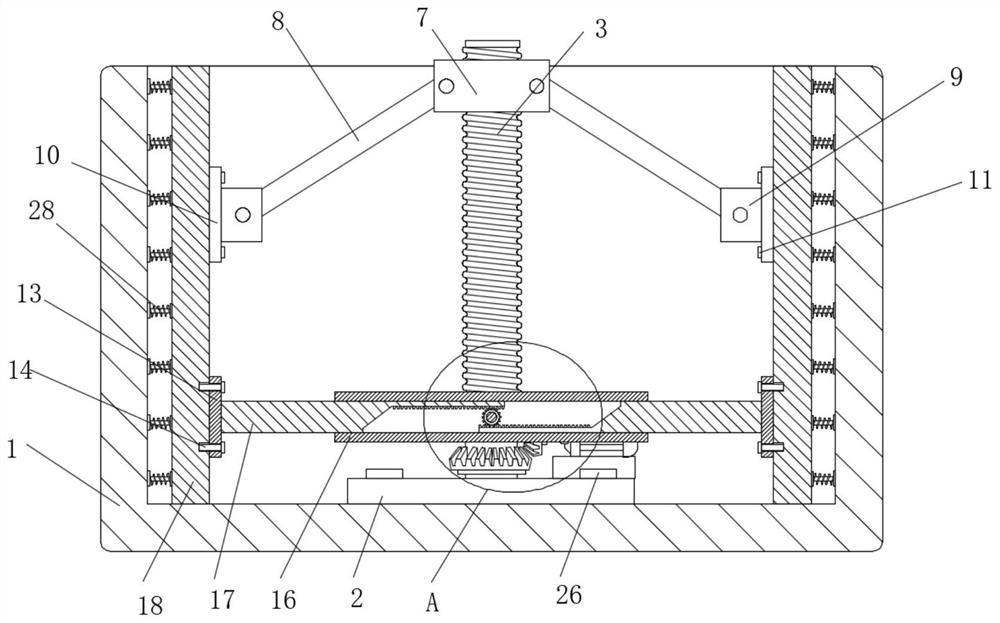

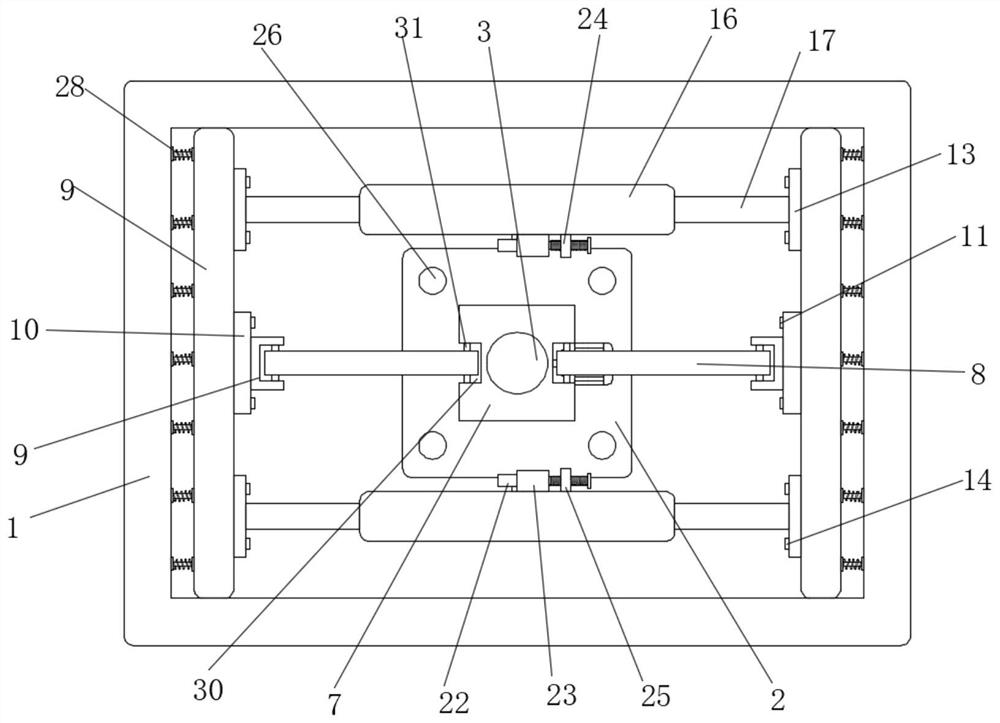

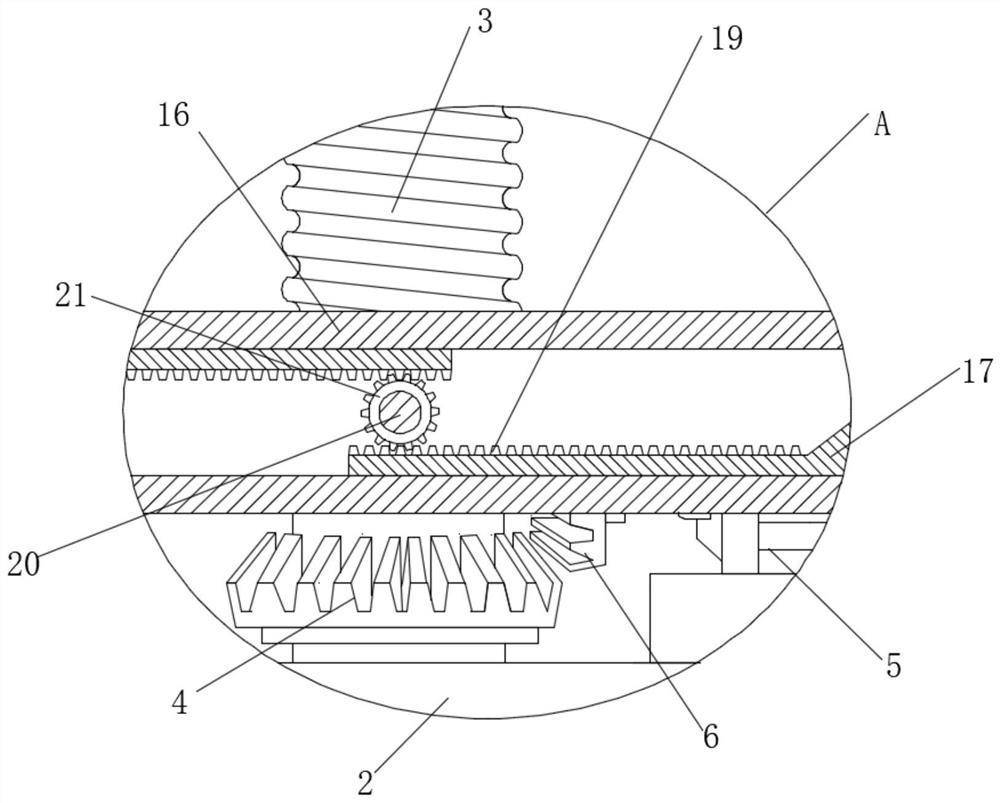

[0031] refer to Figure 1-7 , a support device for foundation pit construction, comprising a foundation pit 1, a fixed base plate 2 is fixedly connected to the inner wall of the bottom of the foundation pit 1, and a screw 3 is connected to the top of the fixed base plate 2 in rotation, and the inner walls on both sides of the foundation pit 1 are tightly connected. A support plate 18 is bonded, and the top of the fixed bottom plate 2 is provided with a driving assembly for supporting the support plate 18. Two symmetrical second fixed plates 13 are fixedly connected to the sides where the two support plates 18 are close to each other. The two support plates 18 are provided with a plurality of second threaded holes 15 on the approaching side, and the side of the second fixed plate 13 away from the support plate 18 is equidistantly arranged with a plurality of second bolts 14, and the plurality of second bolts 14 all pass through the second fixing plate 13 and extend into the sec...

Embodiment 2

[0033]This embodiment is improved on the basis of Embodiment 1: the driving assembly includes a rotating motor 5 fixedly connected to the top of the fixed bottom plate 2, the output shaft of the rotating motor 5 is fixedly connected with a driving bevel gear 6, and the outer wall of the screw 3 is fixedly sleeved. There is a driven bevel gear 4, and the driven bevel gear 4 and the driving bevel gear 6 are meshed. The outer wall of the lead screw 3 is threaded with a lead screw nut 7, and both sides of the lead screw nut 7 are provided with rotating grooves 30, and the two rotating Both sides inner walls of groove 30 are all rotatably connected with rotating rod 31, and the outer walls of two rotating rods 31 are fixedly connected with connecting rod 8, and the ends of two connecting rods 8 away from leading screw nut 7 are all rotatably connected with fixed block 9, fixed The side of the block 9 away from the lead screw nut 7 is fixedly connected with a first fixed plate 10, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com