System and method for changing gear ranges of an electric vehicle

A technology of power train and axle, applied in the field of systems and methods for changing the gear range of electric vehicles, can solve problems such as time-consuming and inefficiency, and achieve the effect of reducing possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

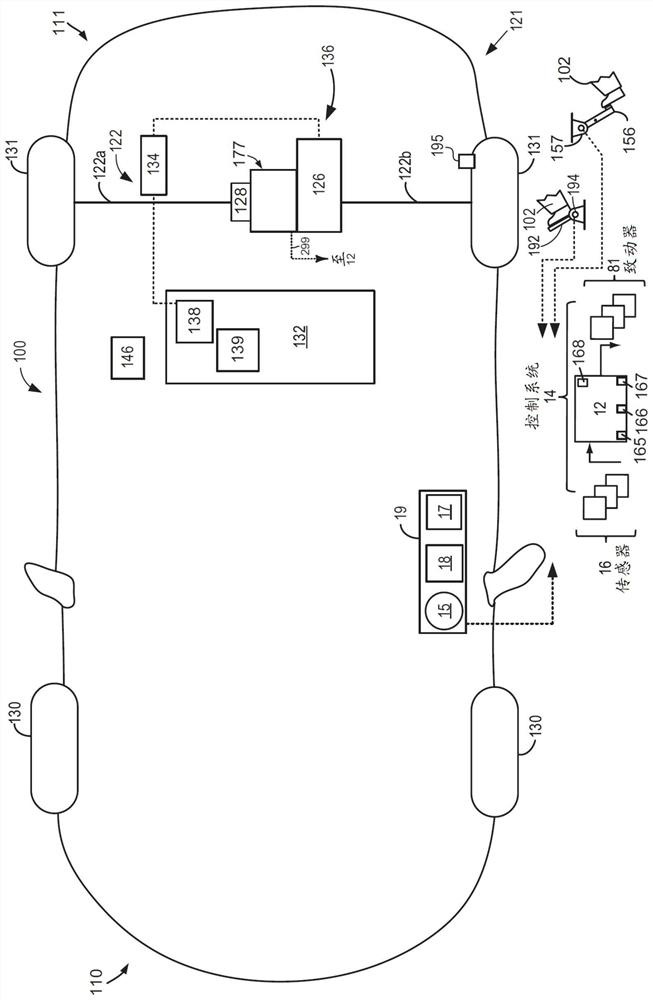

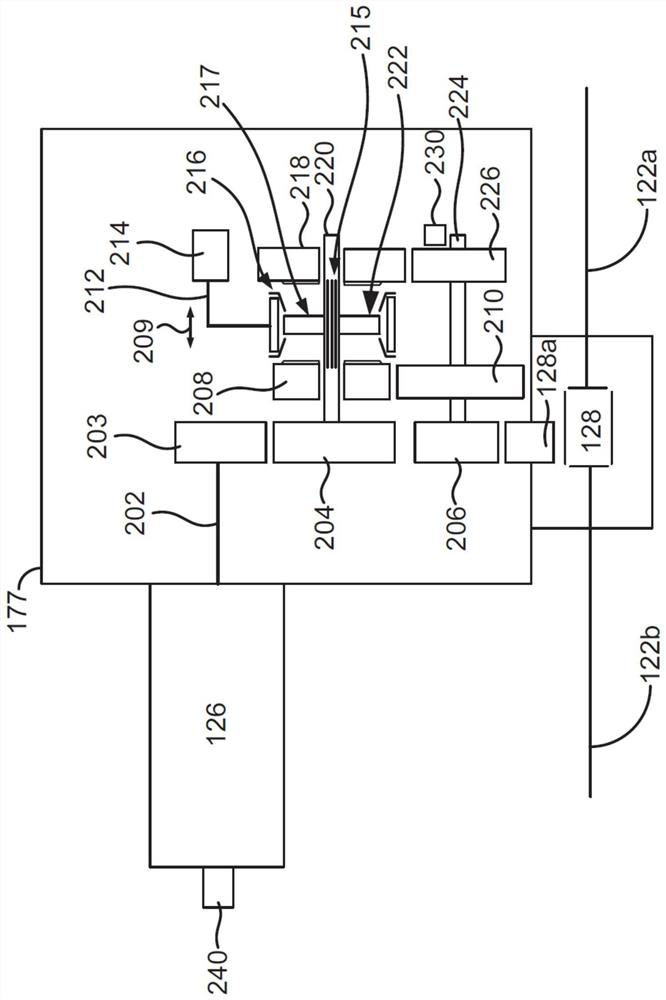

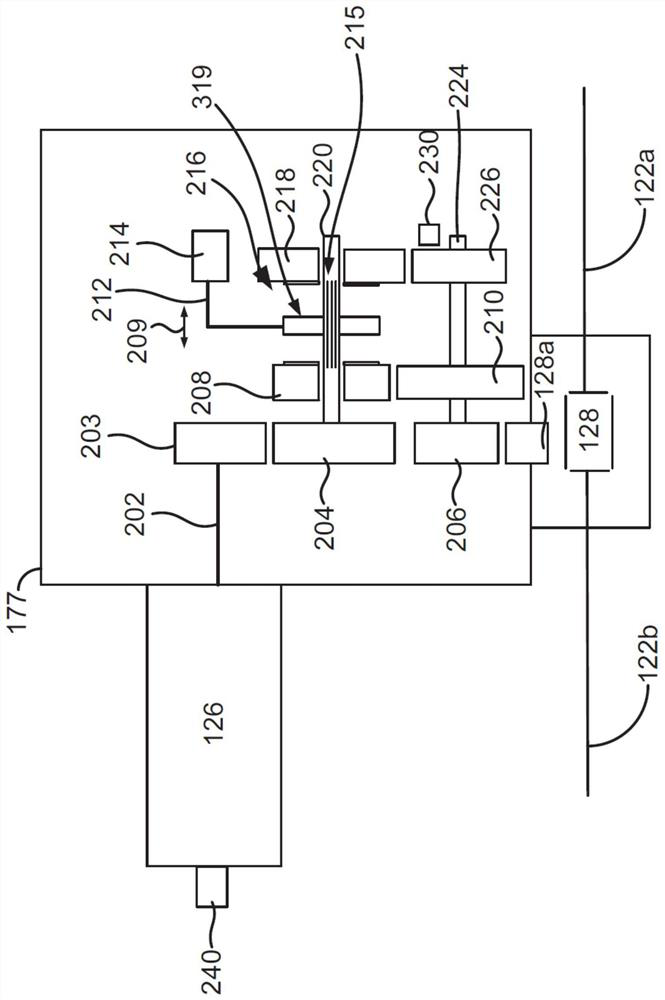

[0011] The following description relates to systems and methods for operating an axle gearbox of a vehicle. The vehicle may be an electric vehicle, and the electric vehicle may include an electric machine coupled to an axle gearbox. The axle gearboxes may be coupled to the differential gear sets of the axles. An axle gearbox may include no friction clutches, but the axle gearbox may include two or more gear ratios. Additionally, the axle gearbox may or may not include a synchronizer for coupling the gears to the shaft of the axle gearbox. Exemplary vehicles and drivelines or powertrains may be figure 1 type shown in . The powertrain may include axles including gearboxes such as figure 2 and image 3 shown. The gearbox can be as Figure 4 to Figure 6 Shown based on Figure 7 and Figure 8 method to operate.

[0012] figure 1 An exemplary vehicle propulsion system 100 is shown for a vehicle 121 . The front of vehicle 121 is indicated at 110 and the rear of vehicle 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com