Lighting module with heat exchange device with closed-cell metal foam

A heat exchange device and lighting module technology, applied in the field of vehicles, can solve the problems of high cost, weight, and high energy efficiency, and achieve the effects of low weight, reduced manufacturing costs, and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

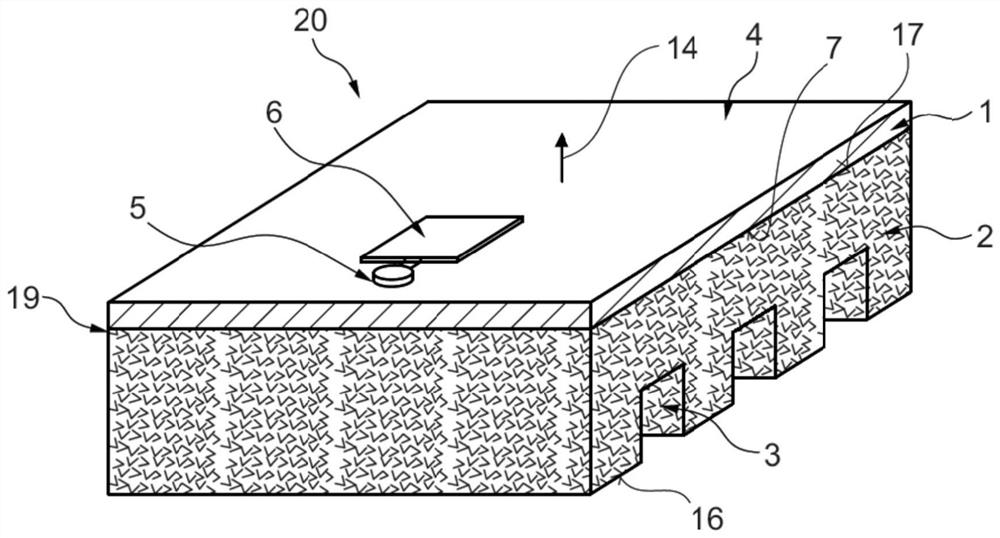

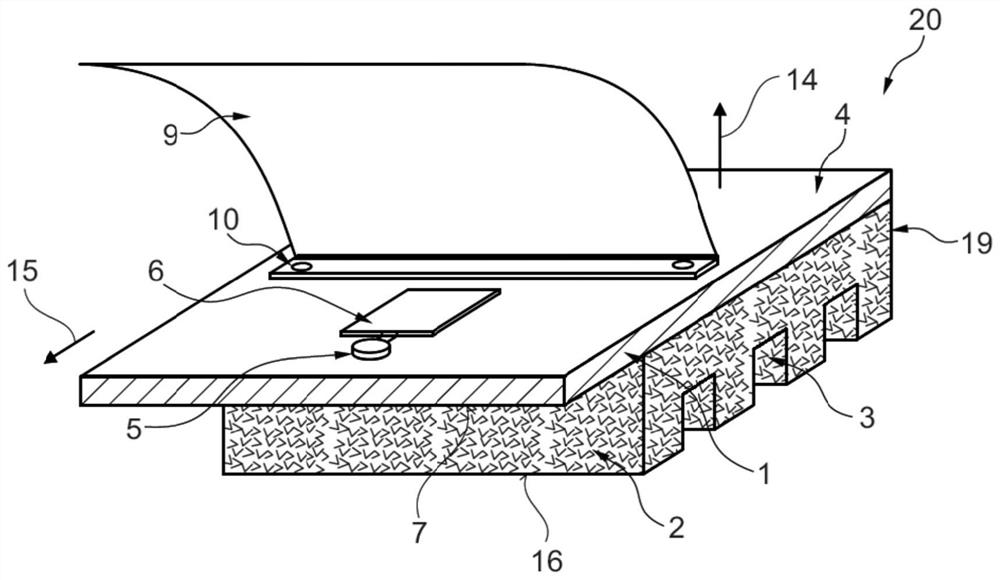

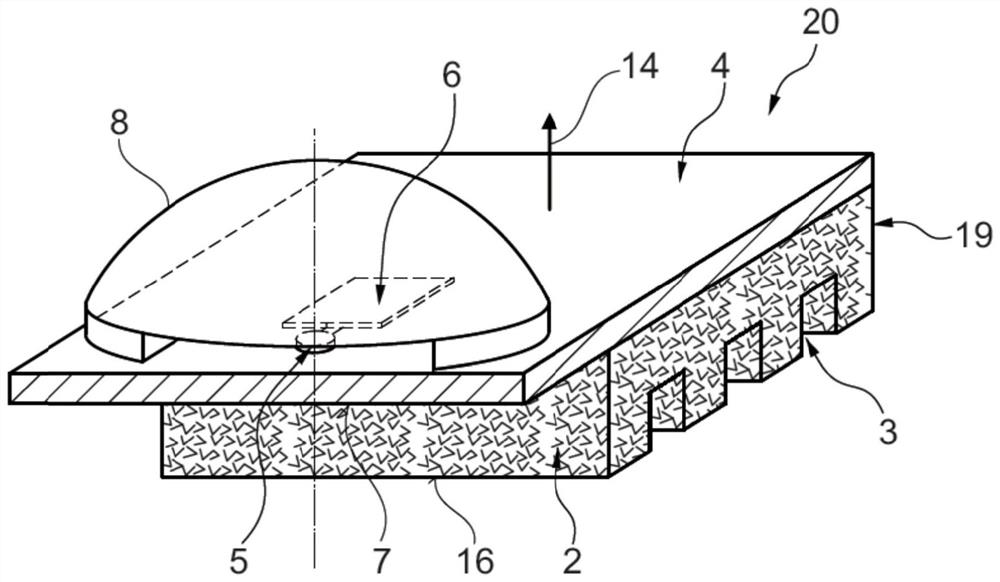

[0032] figure 1A perspective view and a partial sectional view of the lighting module 20 according to the invention are schematically shown. The lighting module 20 comprises a heat exchange device 19 and at least one semiconductor light source 5 (eg LED). The heat exchange device 19 comprises a first metal plate 1 which is directly connected, in particular metallurgically, to the closed-cell metal foam 2 . In particular direct connections for metallurgical connections are best produced by powder metallurgy processes. In this way, a one-piece heat exchange device is made from metal plate 1 and metal foam 2 . The metal plate 1 has an upper side 4 with a surface normal 14 . The metal foam 2 is arranged on the underside 7 of the metal plate 1 . In the variant shown, the semiconductor light sources 5 and the printed circuit board 6 are arranged on the top 4 of the metal plate 1 . The semiconductor light sources 5 will be cooled by heat exchange means 19 . In principle, furthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com