Freeze dryer for vacuum deicing and defrosting

A freeze-drying machine and ice-thawing technology, applied in the field of freeze-drying machines, can solve the problems of long time and low efficiency, and achieve the effects of increasing melting speed, improving production efficiency, and saving defrosting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

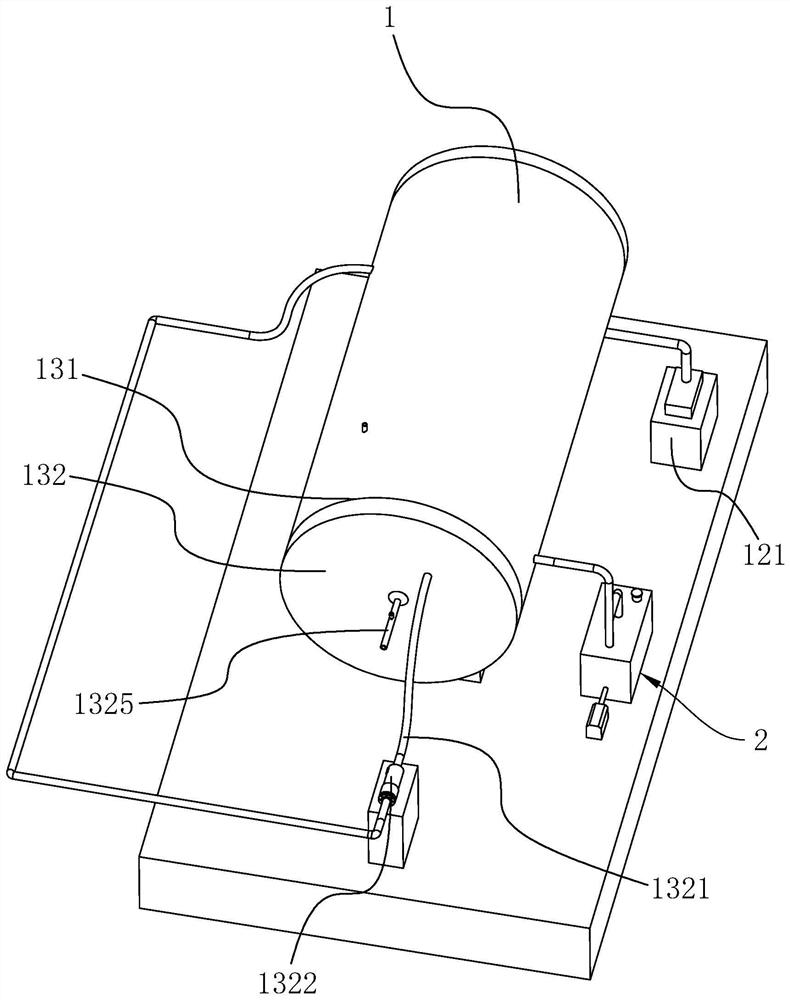

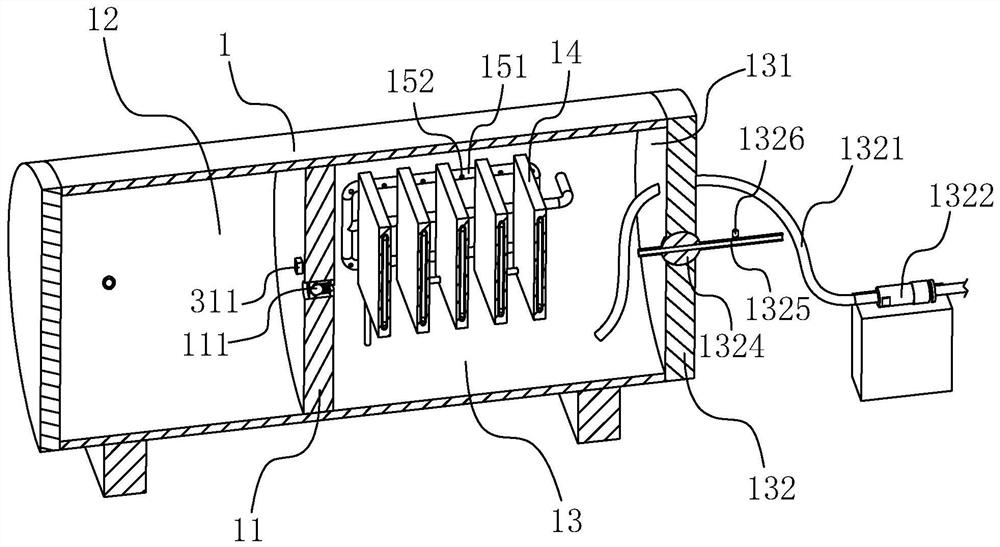

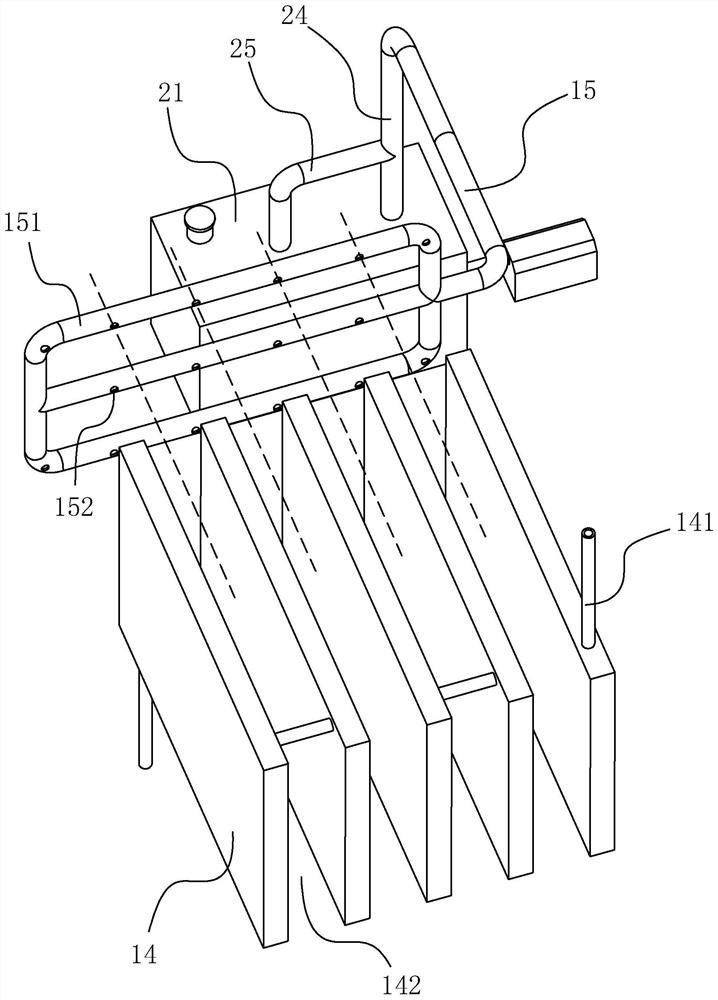

[0042] Embodiment: a kind of lyophilizer of vacuum deicing and defrosting, as figure 1 and figure 2 As shown, a freeze-drying chamber 1 is included, and a partition plate 11 is fixed in the middle of the freeze-drying chamber 1. The partition plate 11 divides the interior of the freeze-drying chamber 1 into a freeze-drying chamber 12 and a defrosting chamber 13. A vacuum pump 121 is fixedly connected to the position of the freeze-drying chamber 1 corresponding to the freeze-drying chamber 12 , and the vacuum pump 121 communicates with the freeze-drying chamber 12 . The partition plate 11 is fixed with an opening and closing valve 111 , and gas can enter the defrosting chamber 13 from the freeze-drying chamber 12 through the opening and closing valve 111 . The vacuum pump 121 vacuumizes the inside of the freeze-drying chamber 12, and is used for the freeze-drying machine to vacuum freeze-dry fruits and vegetables. A large amount of steam is generated during the freeze-drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com