A photoelectric angle sensor based on a two-dimensional material light-absorbing structure array

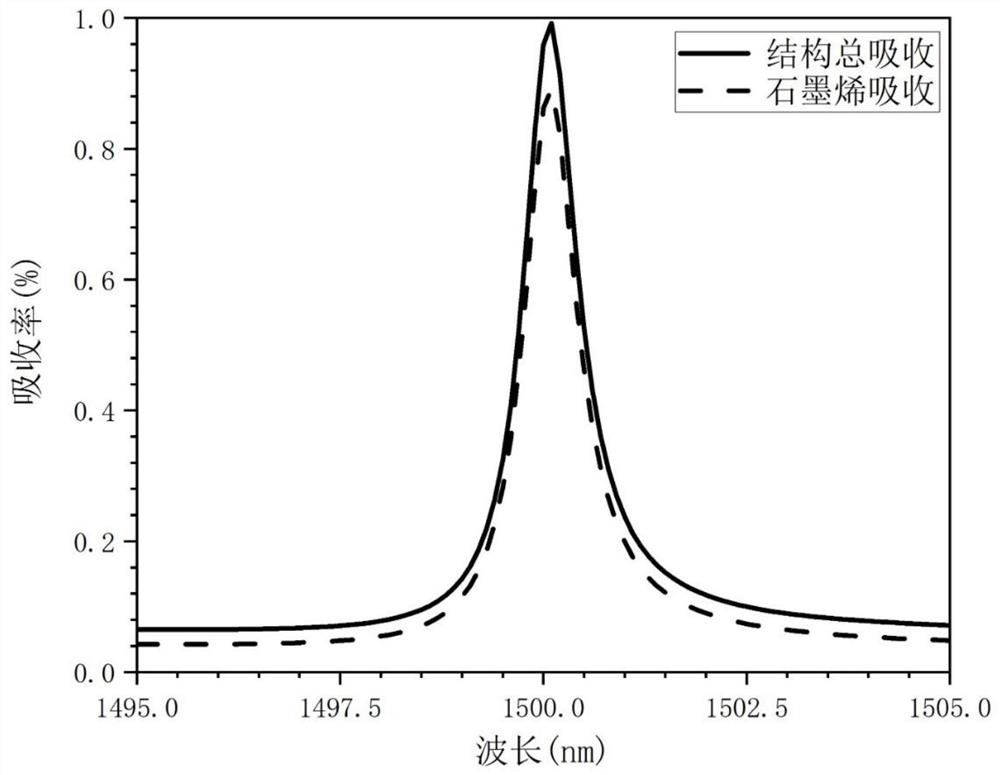

An angle sensor and two-dimensional material technology, applied in the direction of instruments, optical devices, measuring devices, etc., can solve the problems of no public documents, etc., and achieve the effect of increasing quality factor, improving sensitivity and reducing leakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The content of the present invention will be further explained and illustrated in detail below in conjunction with the accompanying drawings. However, the following drawings are only schematic diagrams of idealized implementation cases of the present invention. In order to clearly show the physical structure of the device of the present invention, the schematic diagrams should not be regarded as strictly reflecting the proportional relationship of geometric dimensions. Of course, the illustrated embodiments of the present invention should not be considered limited to the specific shapes of the regions shown in the drawings. In short, the drawings are schematic and should not be considered as limiting the scope of the invention.

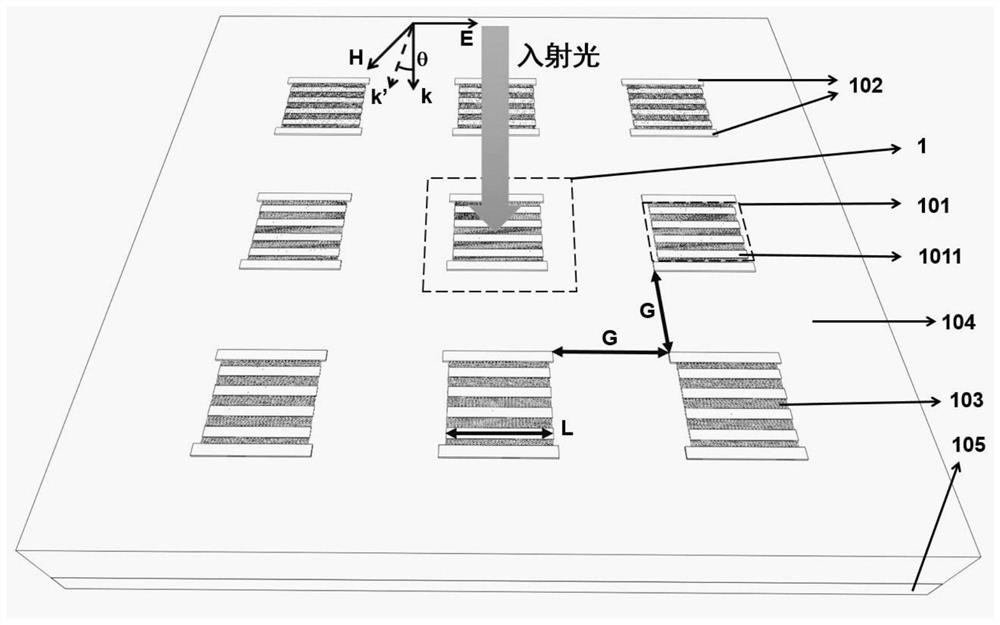

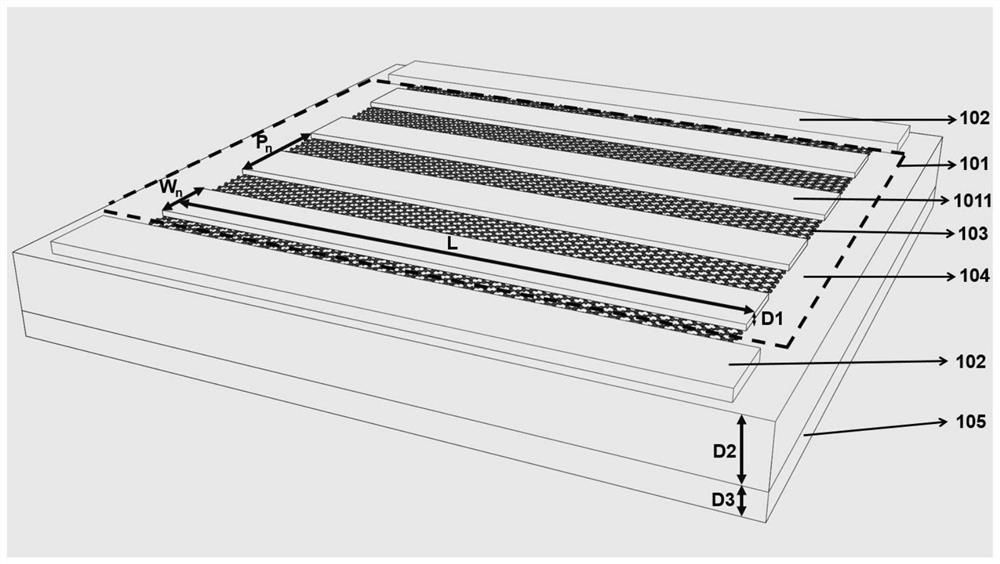

[0032] figure 1 It is a schematic diagram of the overall three-dimensional structure of Embodiment 1 of the present invention. The implementation of the present invention is based on a two-dimensional material light-absorbing structure array....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com