PCCS production data collection method

A technology of production data and data, which is applied in data processing applications, electrical digital data processing, redundant data error detection in calculations, etc., can solve the problems of poor standardization and difficult search of manually collected production data, and achieve perfect production model, the effect of improving management efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

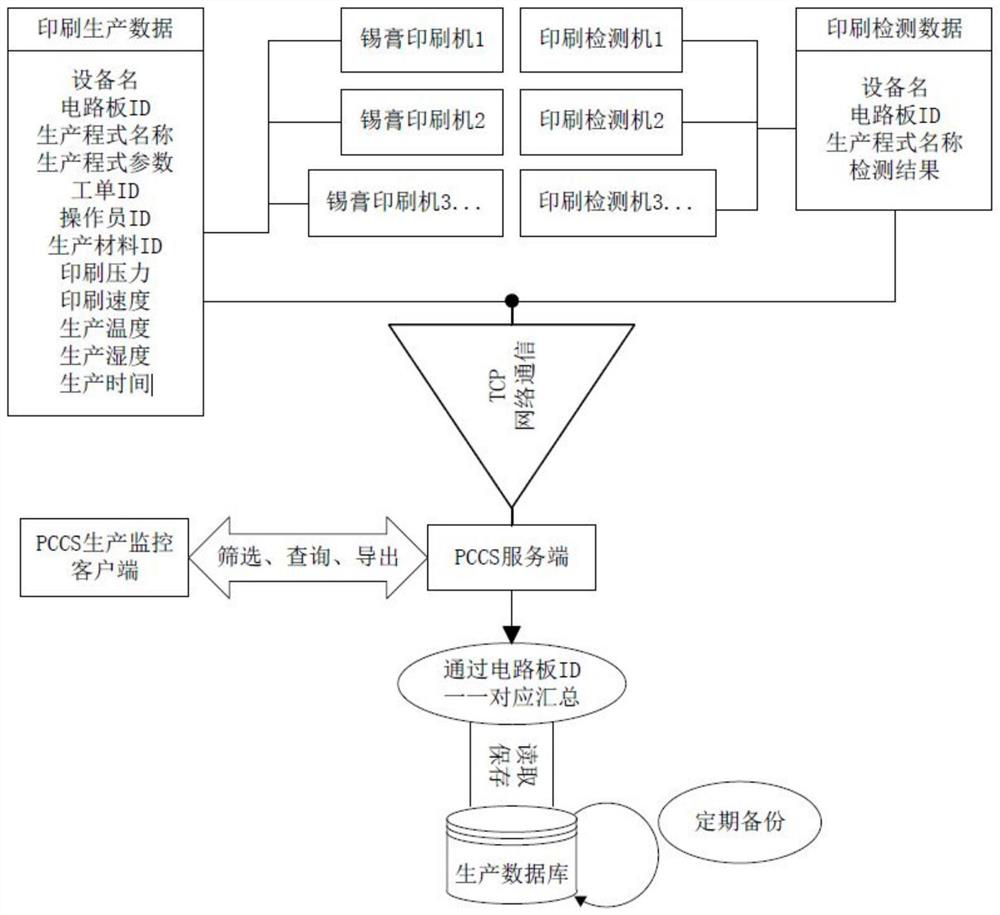

[0032] Such as figure 1 Shown, the present invention provides a kind of PCCS production data collection method, comprises the steps:

[0033] (1) Every time a piece of product is produced by each solder paste printing machine in the production workshop, the printing production data of this piece of product will be sent to the PCCS server;

[0034] Each printing inspection equipment in the production workshop will send the inspection data of this piece of product to the PCCS server after each piece of product is inspected;

[0035] (2) The PCCS ser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com