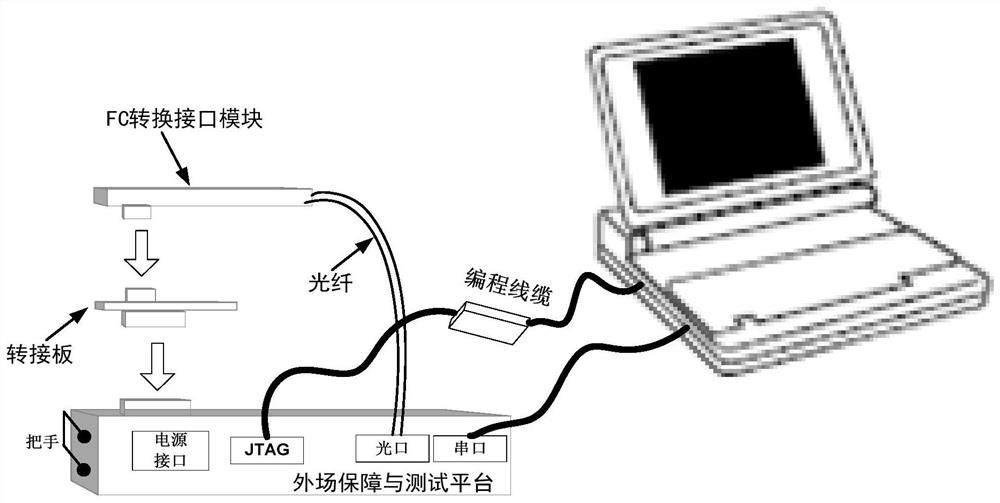

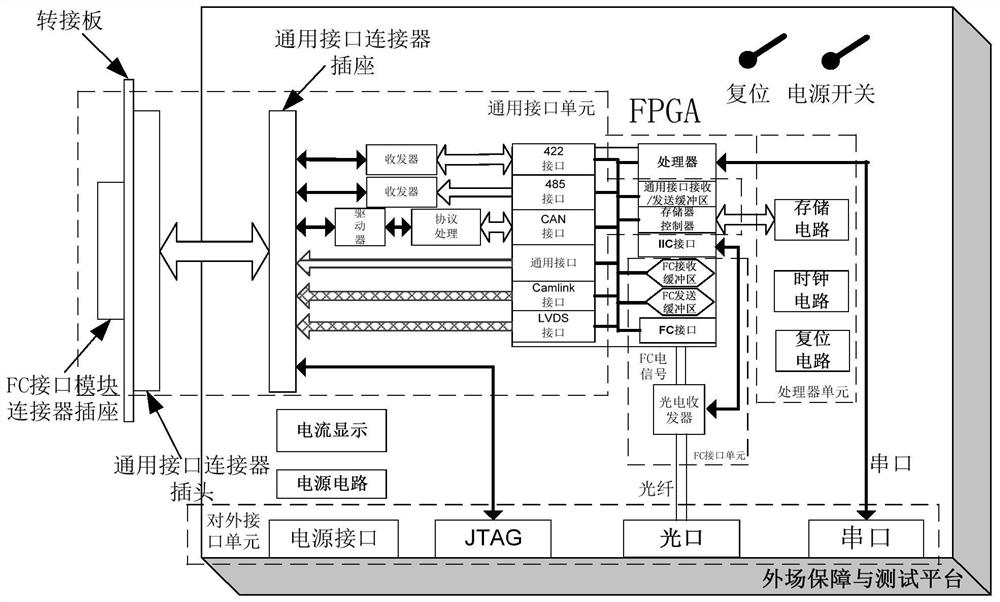

External field guarantee and test platform for universal FC conversion interface module

A technology of converting interface and general interface, applied in the field of field support and test platform, can solve the problems of inability to meet product upgrade and test function requirements, single function of field support platform, no related test methods, etc., to achieve convenient operation and good scalability , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to make the purpose, technical solution and advantages of the present invention more clear, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

[0057] Aiming at the problems of the offline upgrade method of FC conversion interface module products in the background technology, that is, the field support platform has a single function, no relevant test means, and cannot meet the requirements of product upgrades and test functions in the field, a general-purpose method is innovatively proposed. The field support and test platform of the FC conversion interface module, the field support and test platform supports various types of FC conversion interface module products with common interfaces such as Camlink, LVDS, CAN, RS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com