Single-shaft winding machine

A technology of winding machine and winding mechanism, which is applied in coil manufacturing, electrical components, inductance/transformer/magnet manufacturing, etc. It can solve the problems of reducing production efficiency and product quality, failing to achieve a high degree of automation, and difficult to accurately grasp the position. , to achieve the effect of improving yield rate, facilitating welding operation and high spot welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

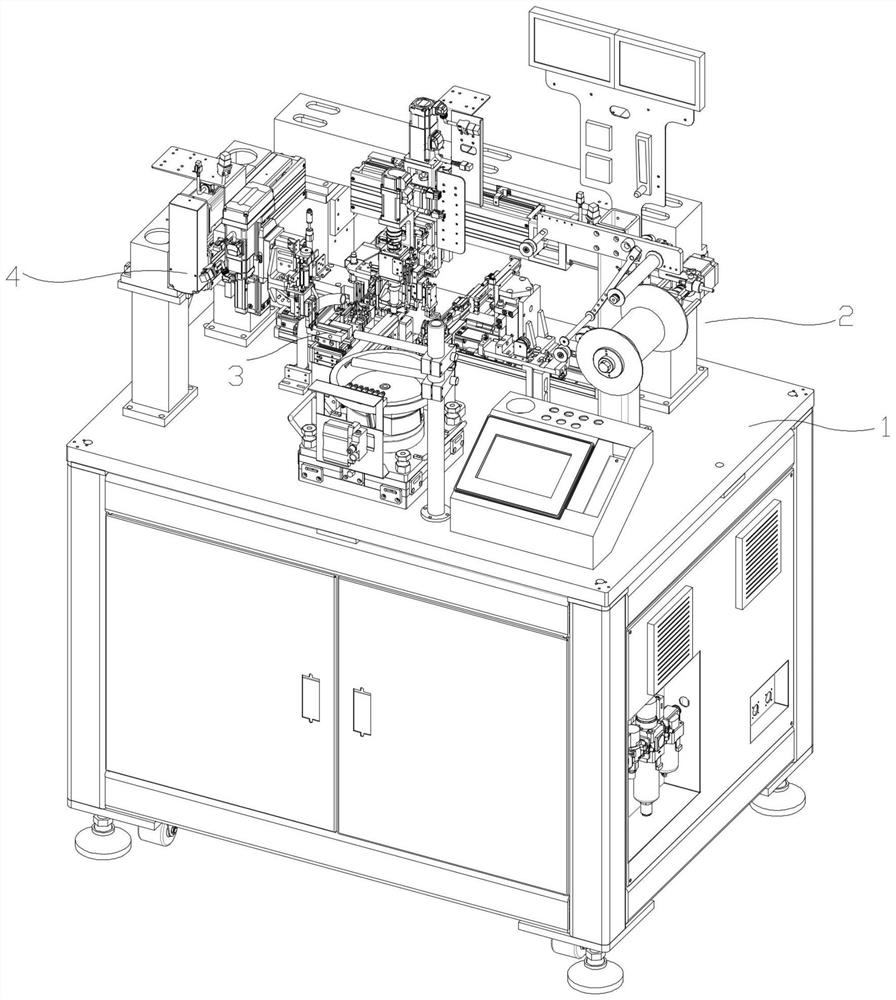

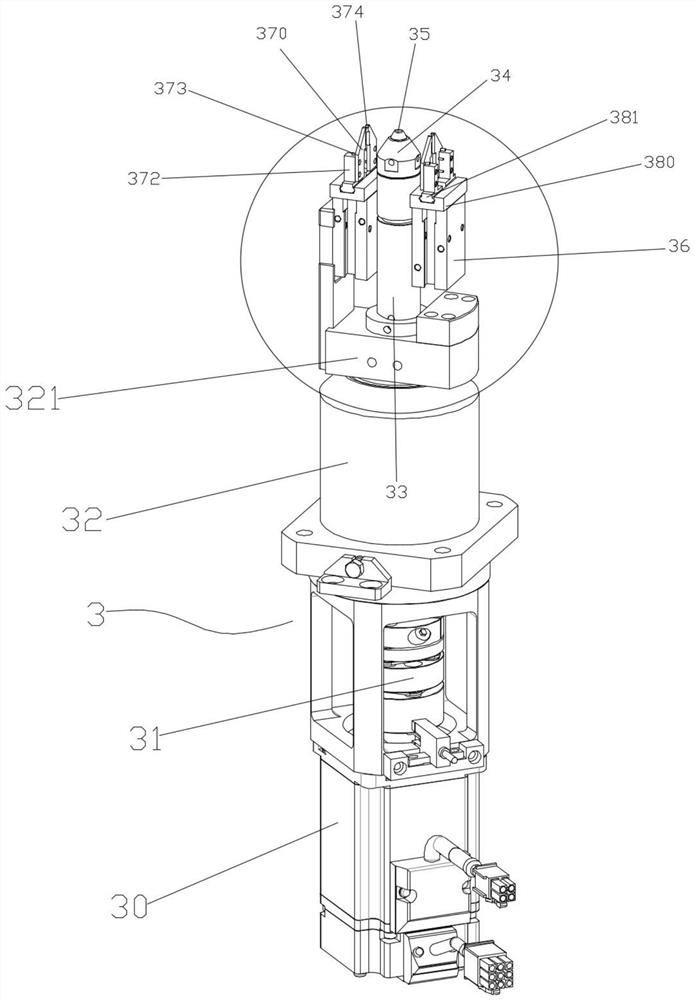

[0040] refer to Figure 1 to Figure 8 As shown, the invention discloses a single-axis winding machine, comprising:

[0041] The chassis 1 and the flying fork double-layer winding mechanism 2 , the inductance polar line turning mechanism 3 and the winding induction welding mechanism 4 arranged on the chassis 1 .

[0042] Among them, the flying fork double-layer winding mechanism 2 includes a polar line outlet unit, a flying fork unit, a cutting unit that can cut the polar line and pull a new polar line to the flying fork unit, and a conveying unit that clamps and delivers the inductance .

[0043] Preferably, the pole line outlet unit includes several roller shaft assemblies with different heights for adjusting the tension of the pole line, which can well improve the quality of the outgoing line, thereby improving the quality of the upper line.

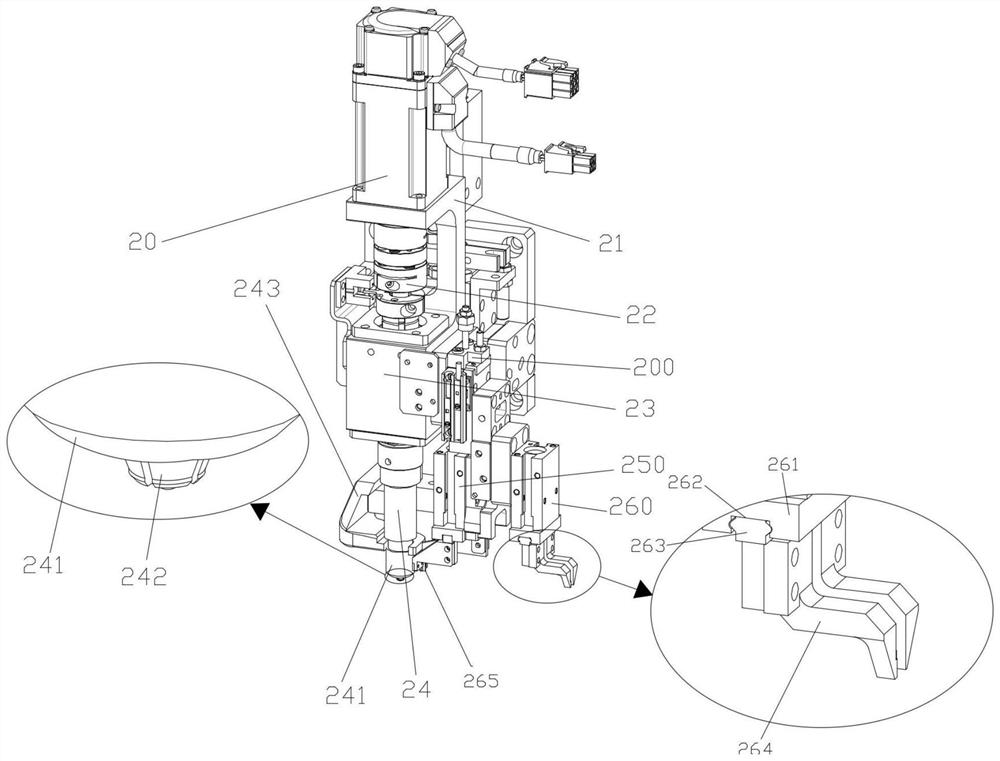

[0044] Preferably, the conveying unit includes a clamping and rotating drive source 20, the above-mentioned clamping and rotating d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com