Cable stripping device of logistics sorting machine

A technology of stripping device and sorting machine, which is applied in the direction of cable installation device, cable installation, disassembly/armored cable equipment, etc., which can solve the problems of low practicability, insufficient size of wire stripper, laborious stripping, etc. Achieve the effect of avoiding labor time-consuming and labor-intensive hand-held cutting, improving practical performance and convenient cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

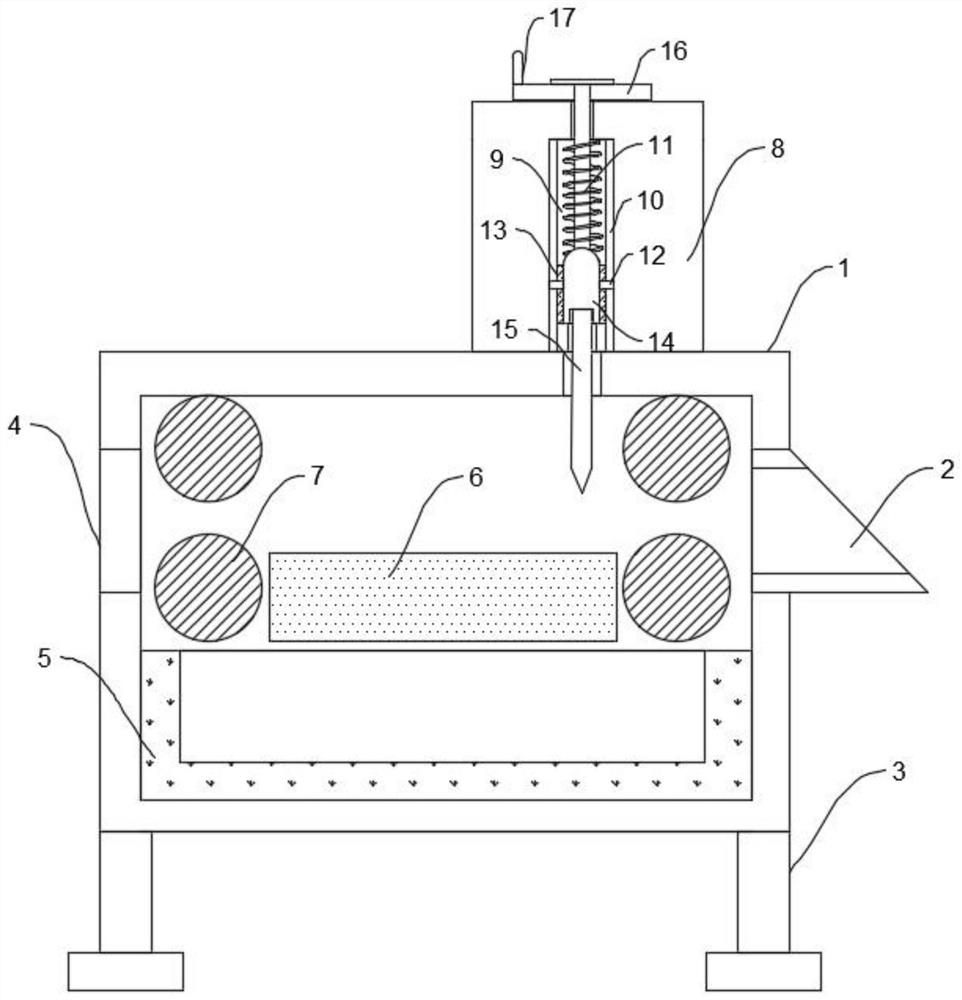

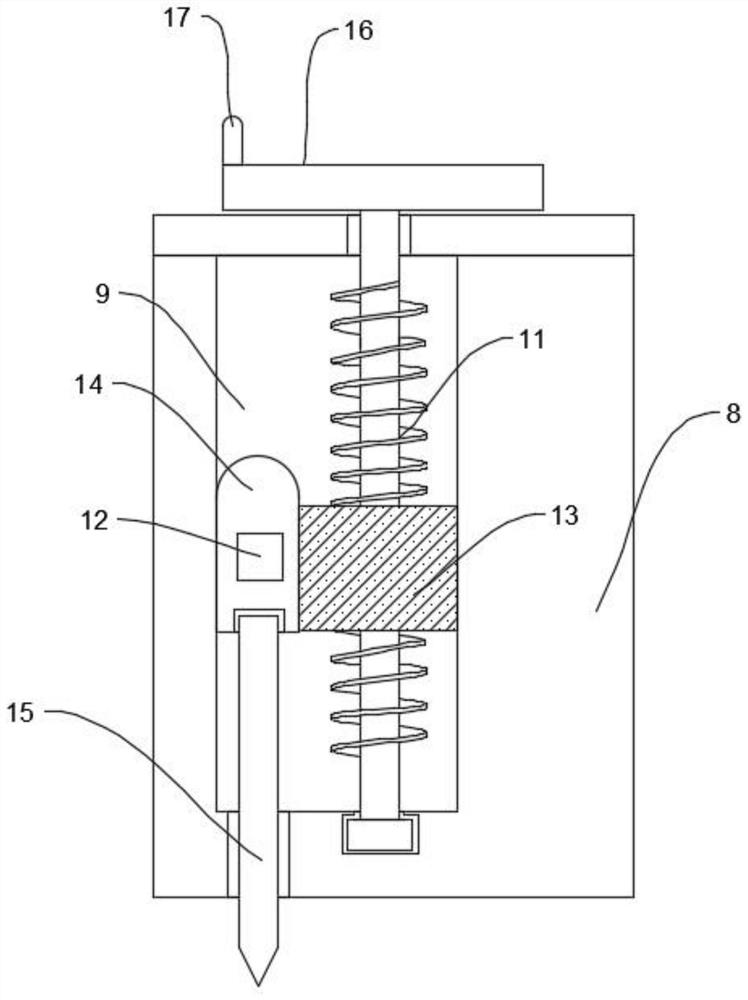

[0027] Example 1, such as Figure 1-4 As shown, the present invention provides a cable stripping device for logistics sorting machines, comprising a device housing 1, a cutting body 8 is fixed on the top of the device housing 1, and an adjustment groove 9 is provided inside the cutting body 8, and the adjustment groove 9 The inner and outer walls of both sides are provided with chute 10, and an adjustment screw 11 is arranged between the inner top surface and the inner bottom surface of the adjustment groove 9, and the top of the adjustment screw 11 extends to the outside of the cutting body 8, and the adjustment screw 11 The outer surface of the sliding sleeve is provided with a fixed block 13, the front surface of the fixed block 13 is fixed with a slider 14, the bottom of the slider 14 is fixed with a cutting knife 15, and the outer surfaces of both sides of the slider 14 are fixed with a slider 12, The outer surfaces of the two sliders 12 slide with the insides of the two ...

Embodiment 2

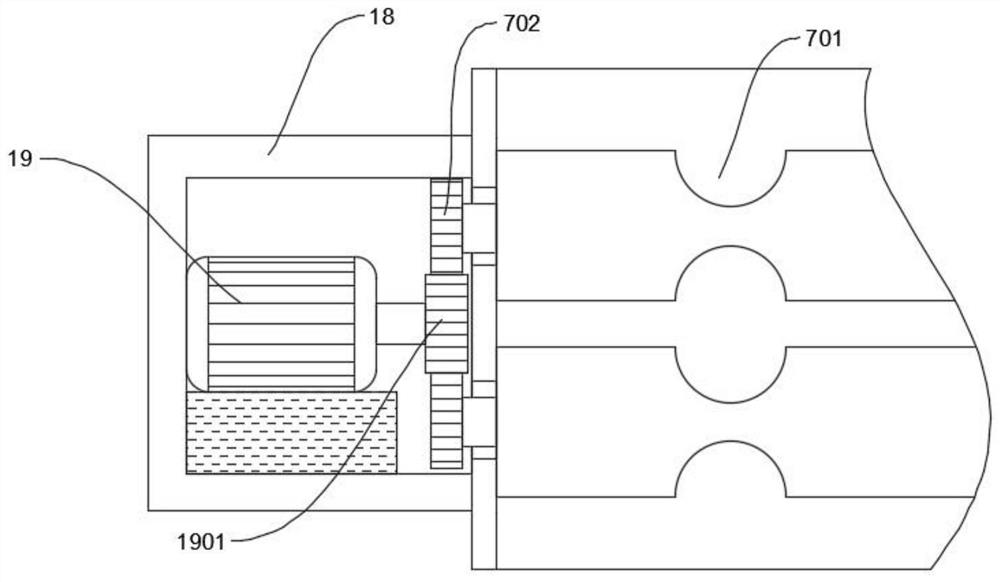

[0029] Example 2, such as Figure 1-3 As shown, the four corners of the bottom of the device shell 1 are fixed with support legs 3, and the rear surface of the device shell 1 is fixed with two protective shells 18, and the inside of the two protective shells 18 is provided with a motor 19, and the output ends of the two motors 19 The first gear 1901 is set on both sides, the outer surface of one side of the device housing 1 is provided with a material inlet 2, the outer surface of the other side of the device housing 1 is provided with a material outlet 4, and the sliding of the device housing 1 is provided with a waste box 5 , the front surface of the waste box 5 is fixed with a pull ring 501, and four transmission rods 7 are fixed between the inner surface walls of the front and rear sides of the device casing 1, and the outer surfaces of the four transmission rods 7 are all provided with annular grooves 701. The two transmission rods 7 are divided into two groups, one end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com