High-reliability brushless motor

A reliability and motor technology, applied in the direction of the casing/cover/support, cooling/ventilation device, electrical components, etc., can solve the problems of noise generation, motor burn-in, and reduce the dust collection effect of the vacuum cleaner, so as to improve the use performance , to solve the effect of loud noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

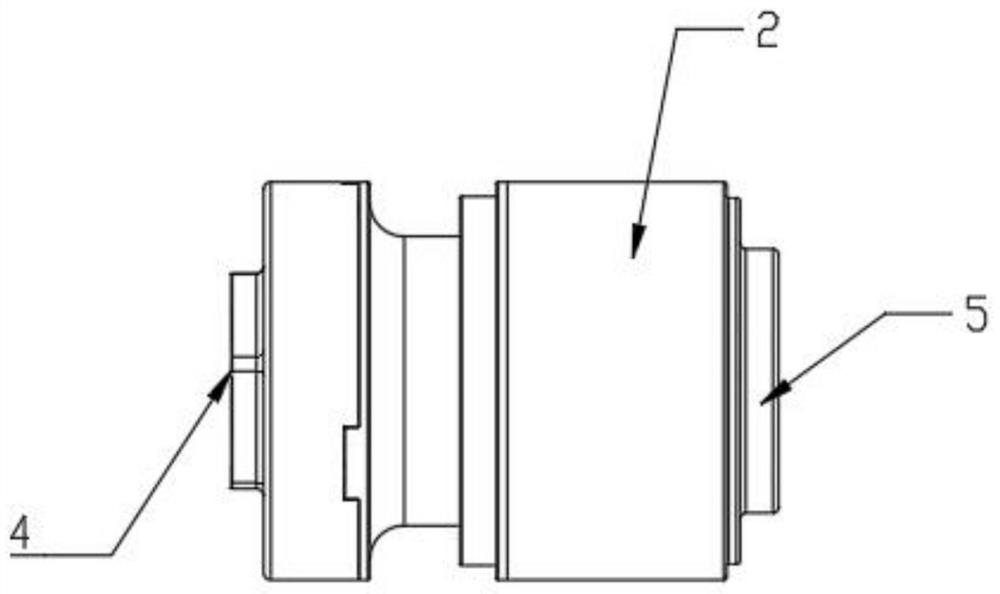

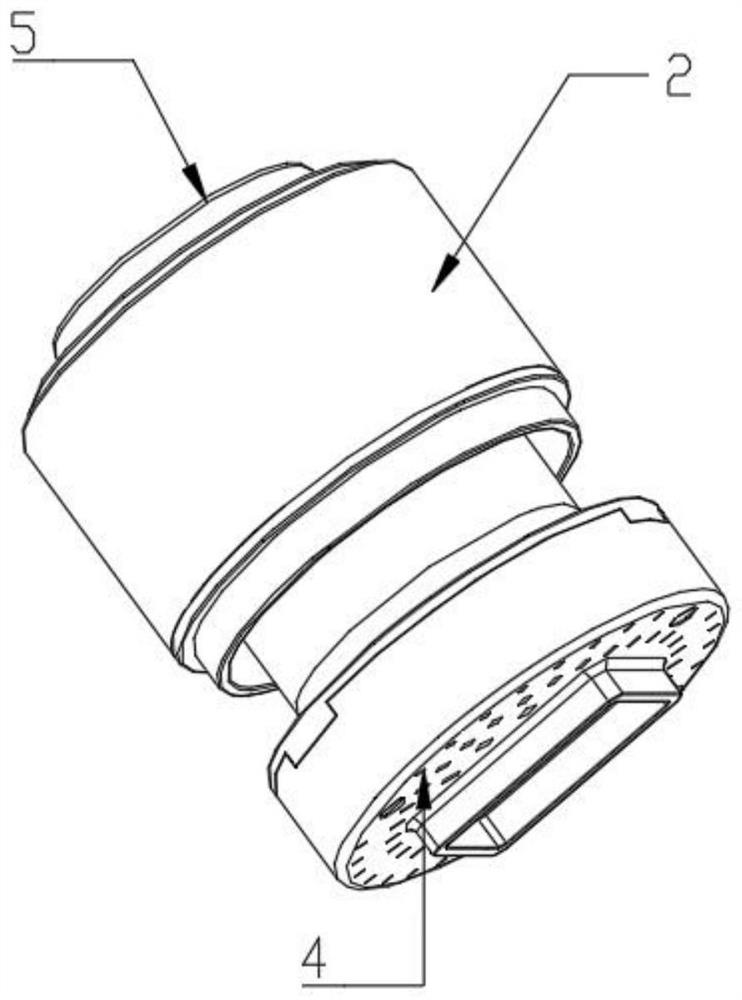

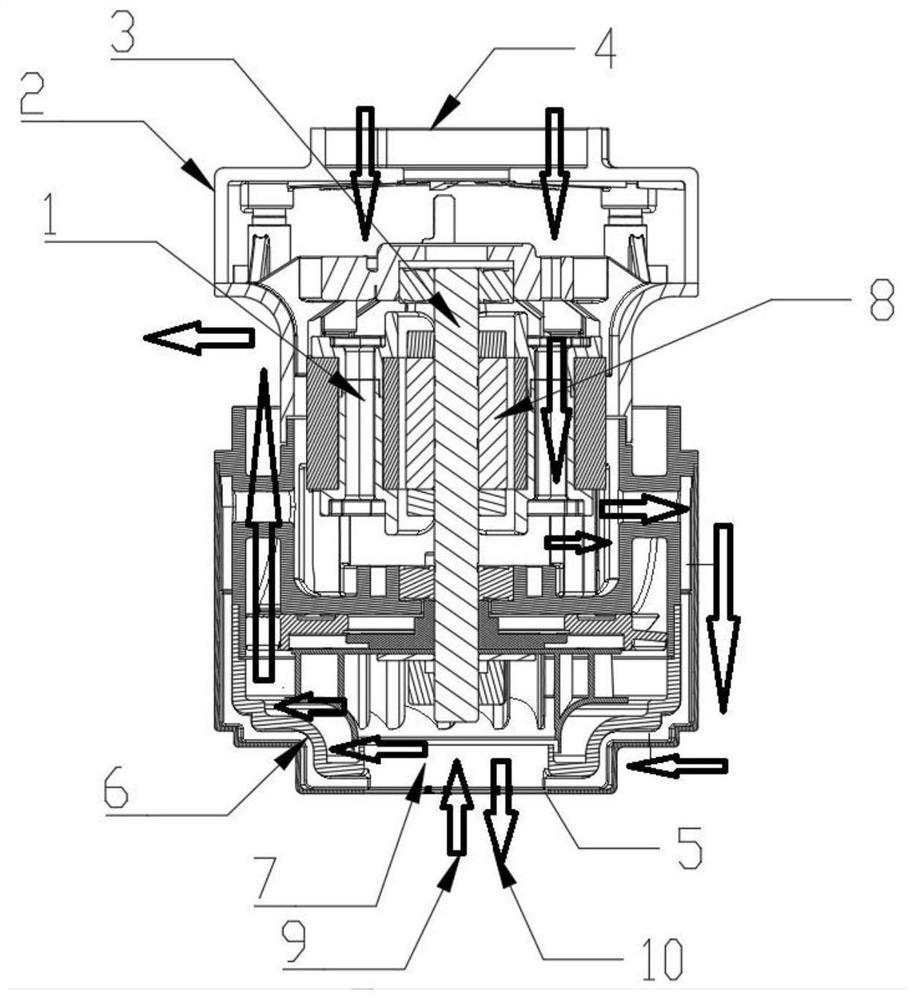

[0029] Example: see Figure 1-3 , the present invention provides a technical solution: a high-reliability brushless motor, including a motor body 1 and a motor casing 2, the motor body 1 has an axially penetrating rotor 3, the motor body 1 is arranged inside the motor casing 2, and the motor casing 2 One end is provided with a top cover 4, the other end of the motor casing 2 is provided with a bottom cover 5, and the rotor 3 is provided with a moving impeller 6;

[0030] There is a negative pressure area 7 at the bottom cover 5, and the negative pressure area 7 is located below the moving impeller 6, and a motor area 8 is provided inside the motor body 1, and the motor area 8 is located above the moving impeller 6;

[0031] There is no mechanical contact and no gap between the motor area 8 and the moving impeller 6;

[0032] The negative pressure area 7 and the moving impeller 6 side form a first airflow pipeline 9 for air circulation;

[0033] The first airflow pipeline 9 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com