Ultrafiltration membrane demoulding method and device

A demoulding device and ultrafiltration membrane technology, applied in ultrafiltration, chemical instruments and methods, membrane technology, etc., can solve problems such as increasing production costs, shortening the service life of ultrafiltration membrane demoulding devices, and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

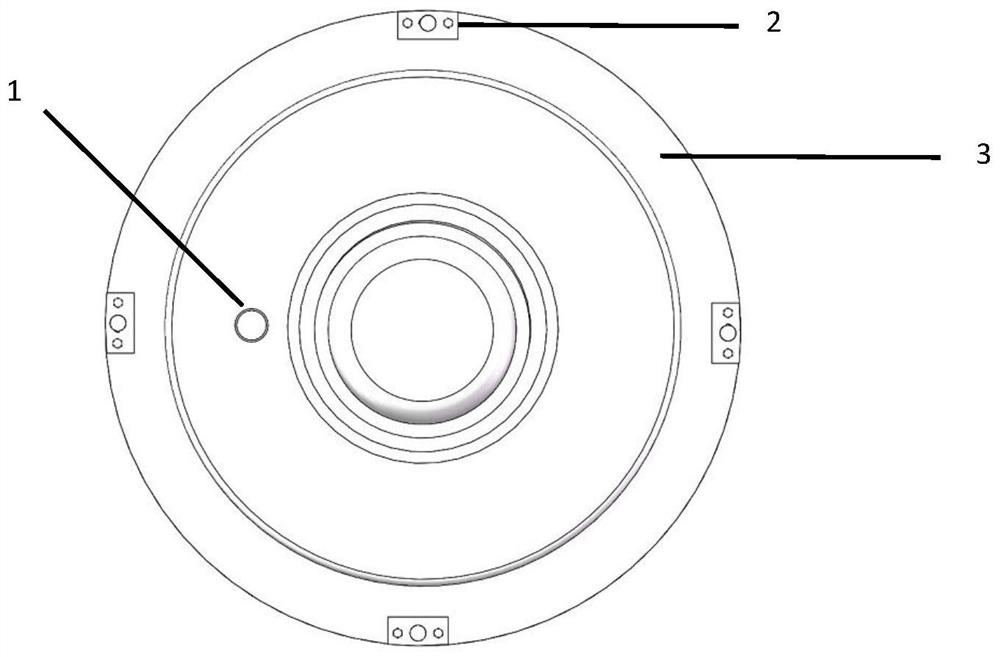

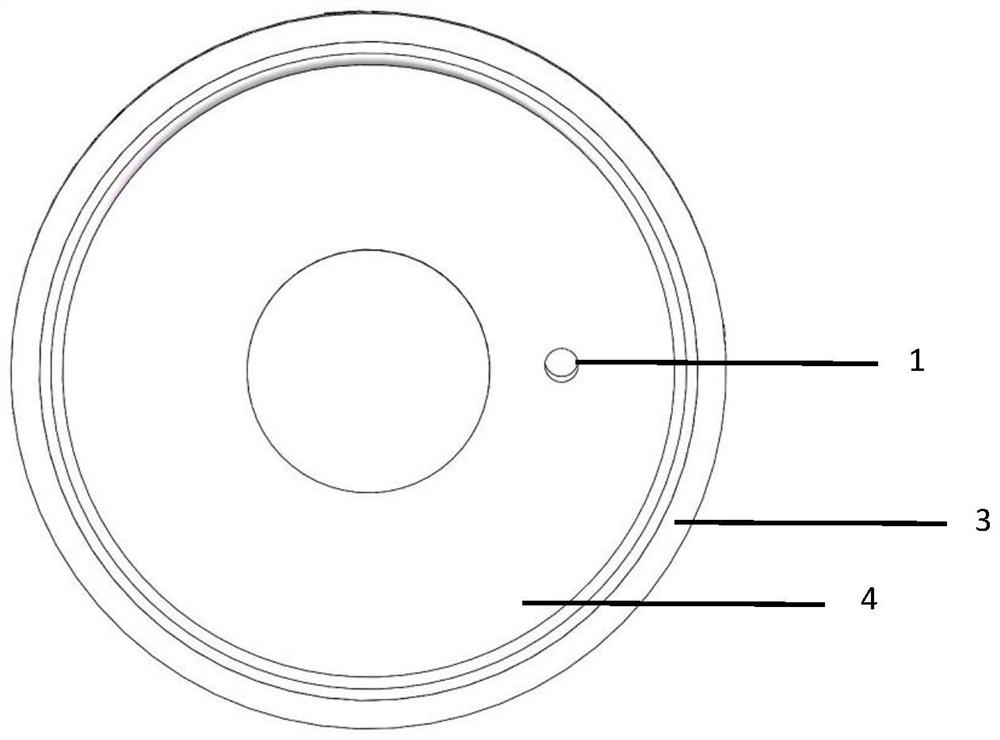

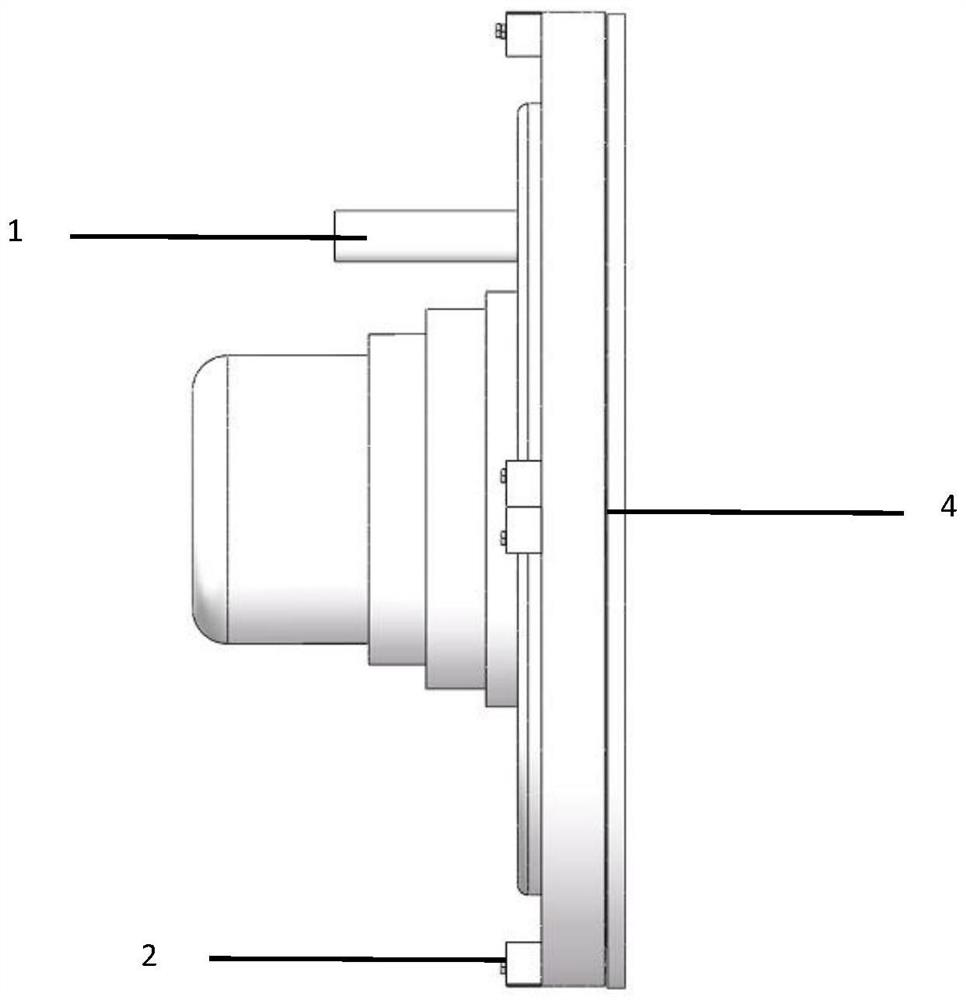

[0021] Embodiment 1 of the present invention: an ultrafiltration membrane demoulding device, comprising a stripper body 4, one side of the stripper body 4 is provided with a glue injection hole 1 and more than two screw trays 2, and the other side of the stripper body 4 is provided with a stripper Mold protective cover3.

[0022] The mold release protective cover 3 is a hollow ring.

[0023] Internal threads are provided in the screw tray 2, and the screw tray 2 is made of stainless steel. Compared with aluminum, stainless steel has higher hardness, is not easy to wear, and is easy to replace after wear, which greatly prolongs the service life of the demoulding device.

[0024] The ultrafiltration membrane demoulding method includes a demoulding body 4, one side of the demoulding body 4 is provided with a glue injection hole 1 and more than 2 screw trays 2, and the other side of the demoulding body 4 is provided with a demoulding protective cover 3, and the demoulding When th...

Embodiment 2

[0029] Embodiment 2 of the present invention: an ultrafiltration membrane demoulding device, comprising a stripper body 4, one side of the stripper body 4 is provided with a glue injection hole 1 and more than two screw trays 2, and the other side of the stripper body 4 is provided with a stripper Mold protective cover3.

[0030] The mold release protective cover 3 is a hollow ring.

[0031] There are internal threads in the screw tray 2, and the number of the screw trays 2 is preferably 4. The screw tray 2 is made of stainless steel. Compared with aluminum, stainless steel has higher hardness, is not easy to wear, and is easy to replace after wear. The service life of the demoulding device is greatly extended.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com