Large-sized cylinder high-precision multi-degree-of-freedom alignment device controlled by support vehicle group

A large-scale cylinder and alignment device technology, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve problems such as deformation, accidental accidents of the material in the cylinder, and large force on the cylinder, reducing the number of labor, The effect of reducing the risk of barrel deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

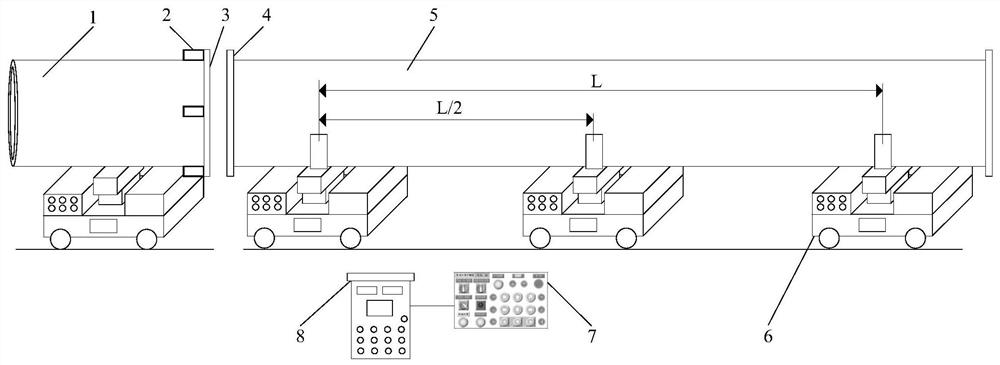

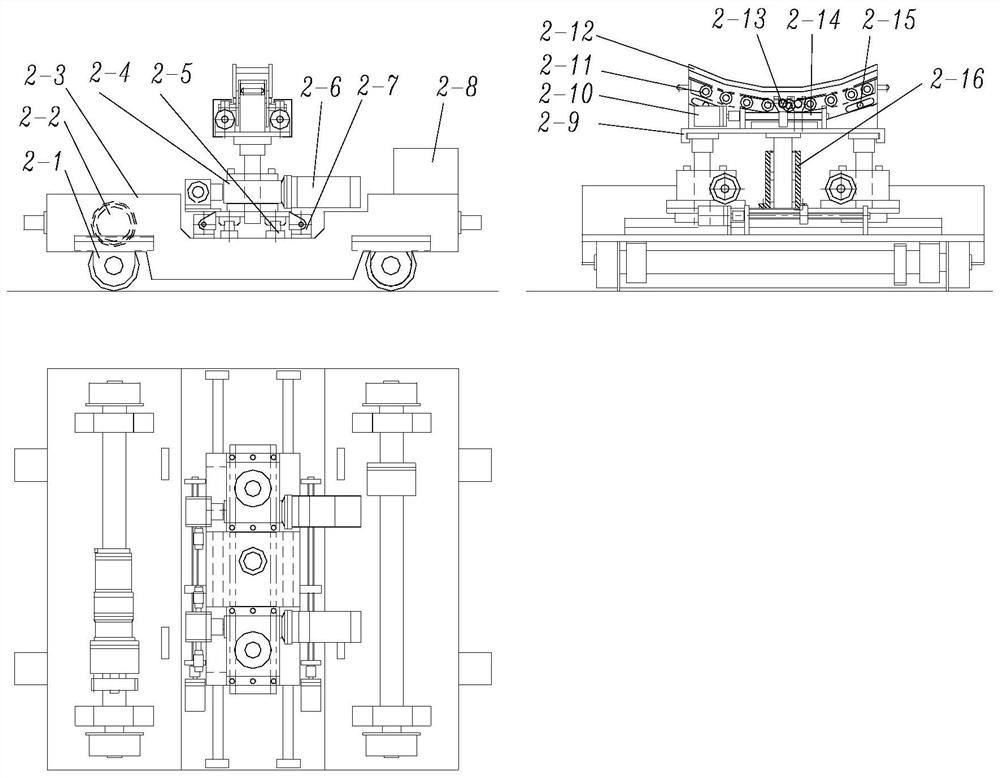

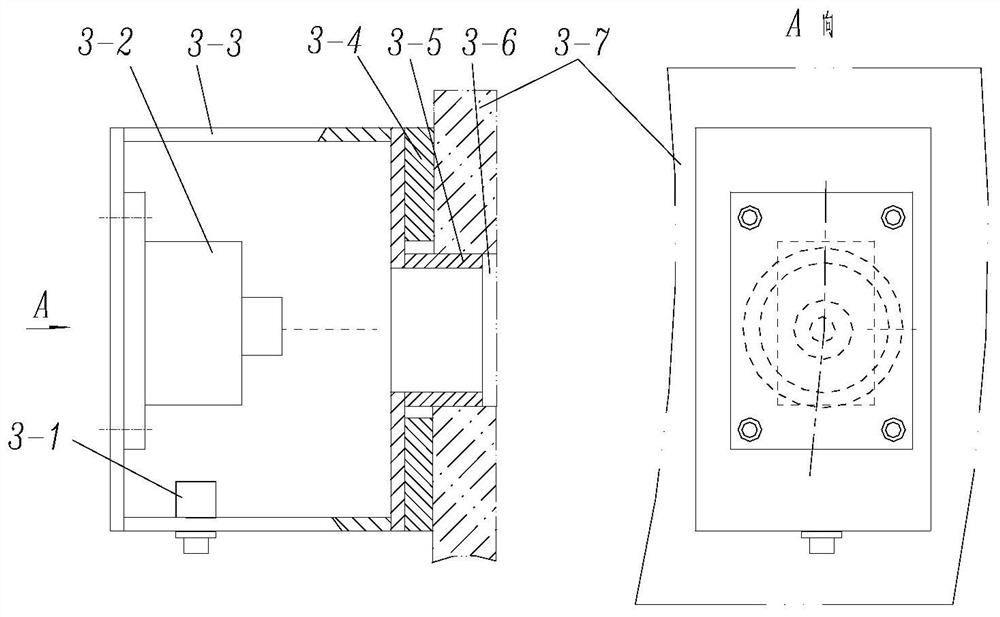

[0036] The present invention proposes to use 3 support vehicles to simultaneously support the cylinder body and to push the cylinder body to move or rotate at the same time as an active drag trolley, so as to realize a multi-point supporting and multi-point force-bearing drag system, disperse the force, and make the cylinder body The stress is uniformly differentiated, which solves the problem of the deformation of the cylinder caused by the local force of the cylinder being too large under the condition of a single point of force in the past.

[0037] At the same time, by controlling the synchronous or proportional movement of the three support vehicles, the movement of the cylinder body in four degrees of freedom, forward and backward, up and down, left and right lateral m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com