Rotary household rice steamer chamfering device

A chamfering and rotary technology, which is applied to grinding drive devices, machine tools suitable for grinding the edge of workpieces, grinding machines, etc., can solve the problem of long grinding time of rice cooker

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

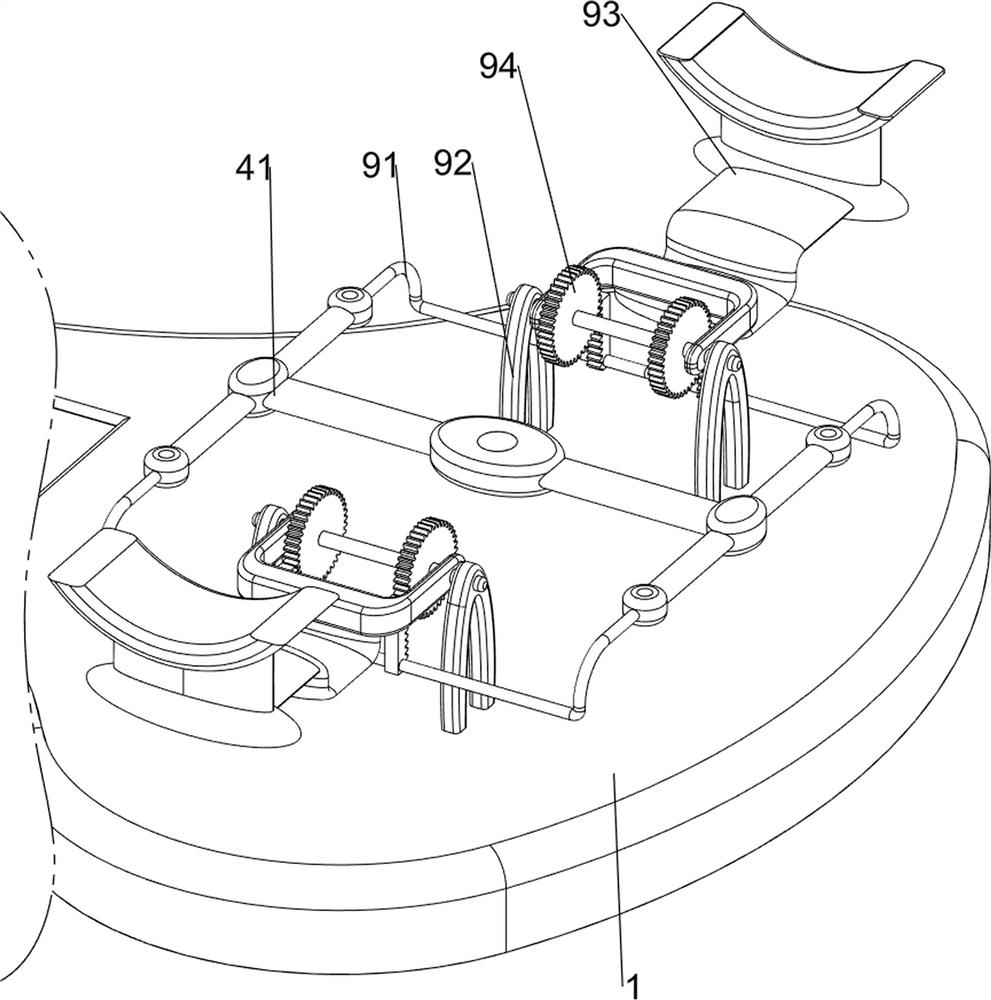

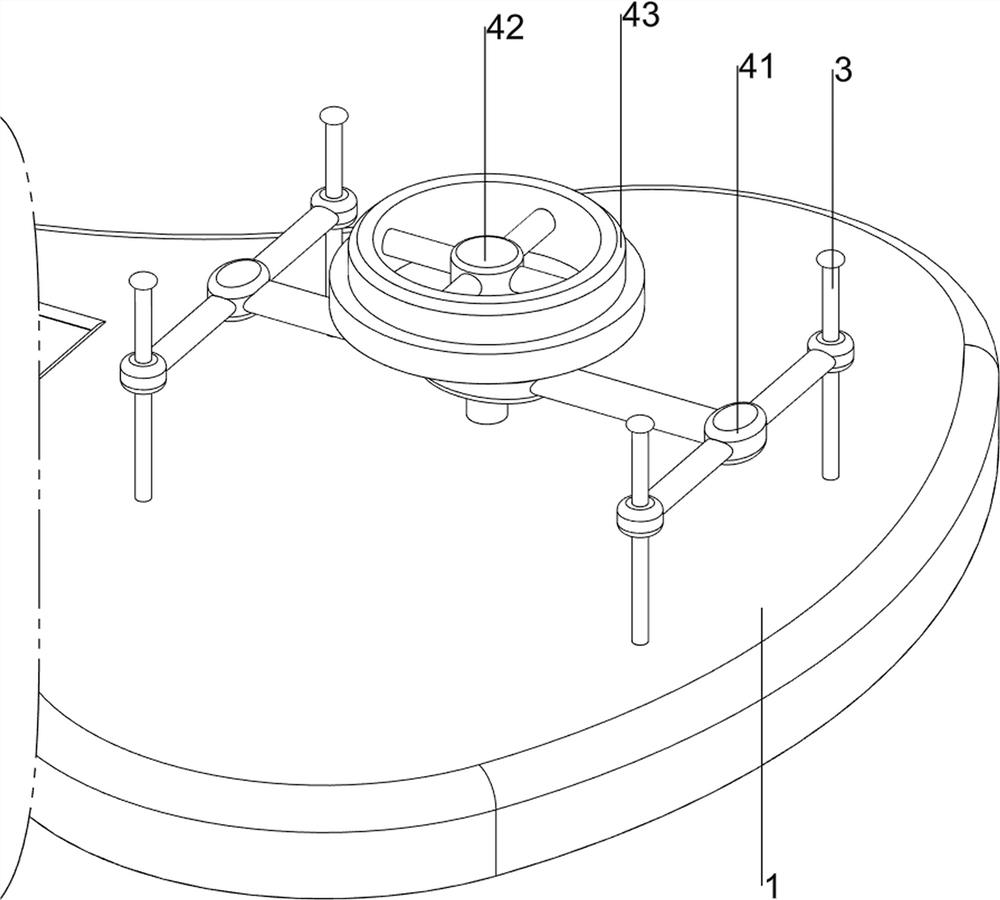

[0057] A kind of rotary household rice cooker chamfering device, such as figure 1 , figure 2 and image 3 As shown, it includes a base 1, a first support frame 2, a first guide rod 3, a fixing mechanism 4 and a frosting mechanism 5, the upper side of the base 1 is provided with a first support frame 2, and the front side of the top of the base 1 is provided with four first A guide rod 3, a fixing mechanism 4 is provided between the four first guide rods 3, and a sanding mechanism 5 is provided on the front side of the first support frame 2.

[0058] When it is necessary to chamfer the edges and corners of the rice retort, put the rice retort on the fixing mechanism 4, and people lift the fixing mechanism 4 upwards to drive the rice retort to move to the bottom of the frosting mechanism 5, and then turn the frosting mechanism 5 to rotate, and the frosting mechanism 5 pairs the rice retort The upper edge is polished and chamfered. After the rice steamer upper edge is polished...

Embodiment 2

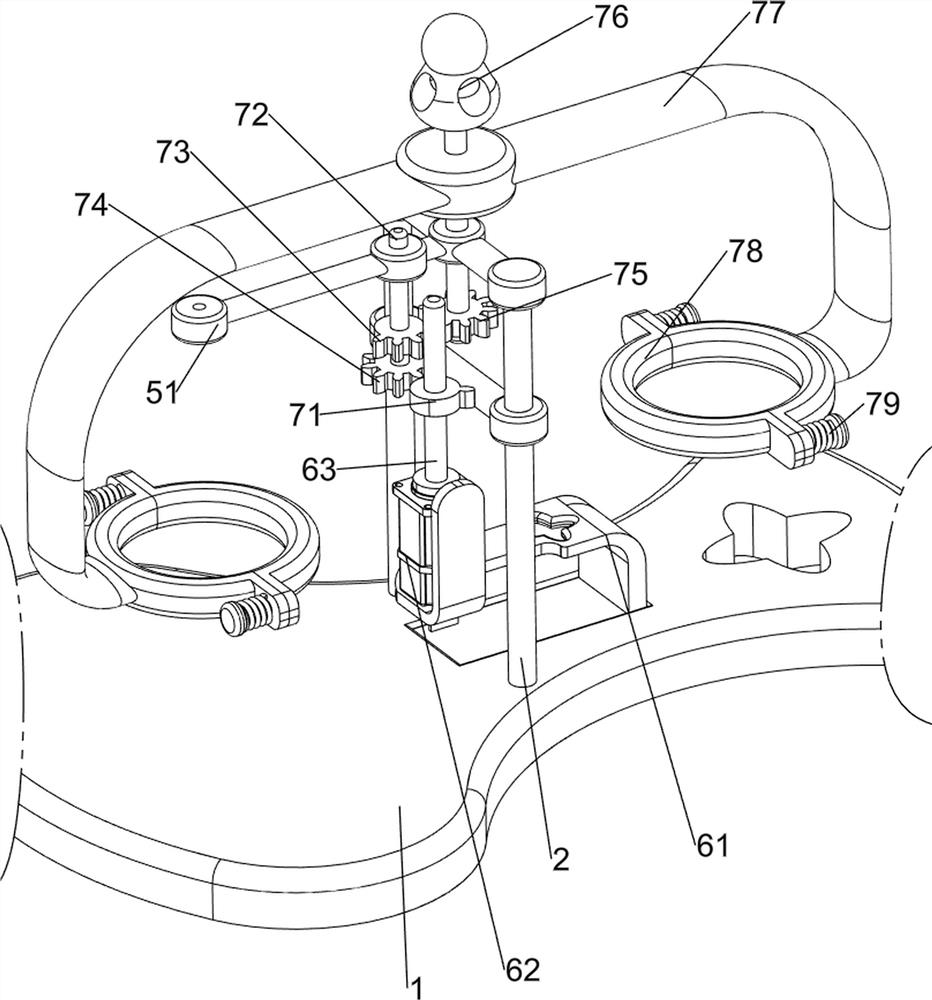

[0064] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, a rotating mechanism 6 is also included. The rotating mechanism 6 includes a second support frame 61, a motor 62, a second rotating shaft 63 and a first transmission assembly 64. The base 1 is provided with a second support frame 61, and the second support frame 61 is provided with a motor 62 , the output shaft of the motor 62 is connected with a second rotating shaft 63 , and a first transmission assembly 64 is wound between the upper side of the second rotating shaft 63 and the first rotating shaft 52 .

[0065] Turn on the motor 62, the output shaft of the motor 62 drives the second rotating shaft 63 to rotate, thereby driving the first transmission assembly 64 to rotate, and then drives the first rotating shaft 52 to rotate, so that the emery wheel 53 rotates to chamfer the rice steamer, after the rice steamer chamfers the corners, Turn off the motor 62, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com