Wood cutting and polishing device for gardens

A technology for cutting and grinding wood, used in grinding drives, woodworking appliances, grinding machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

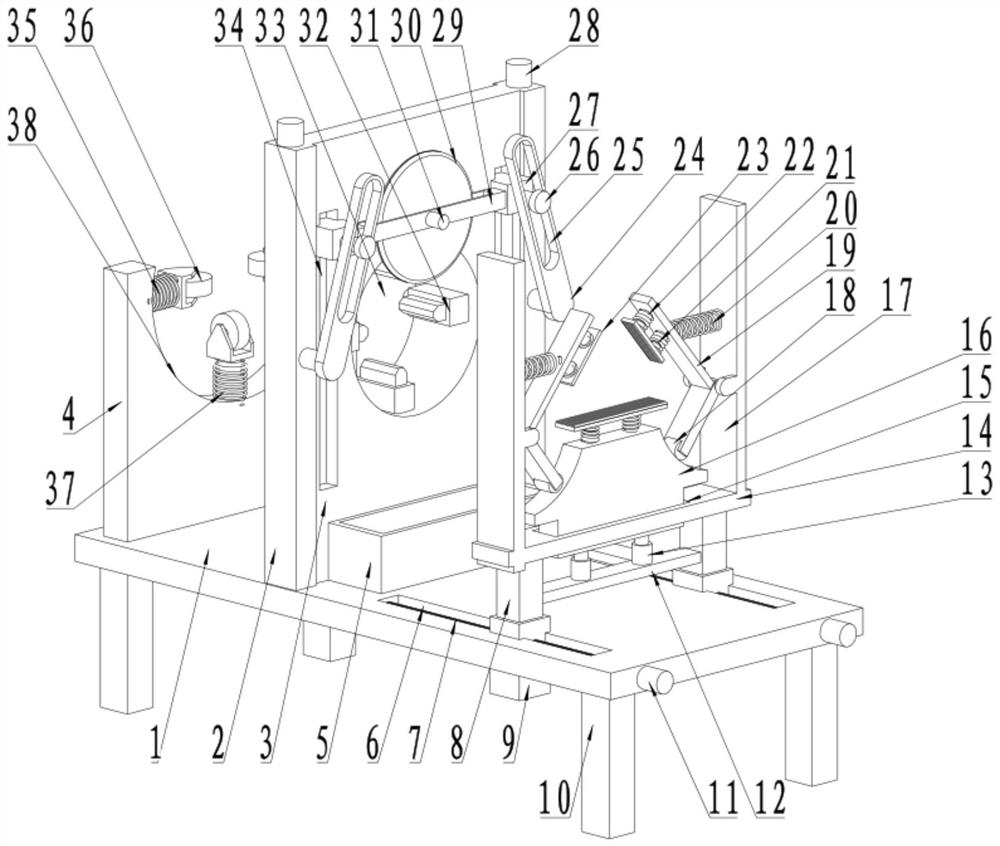

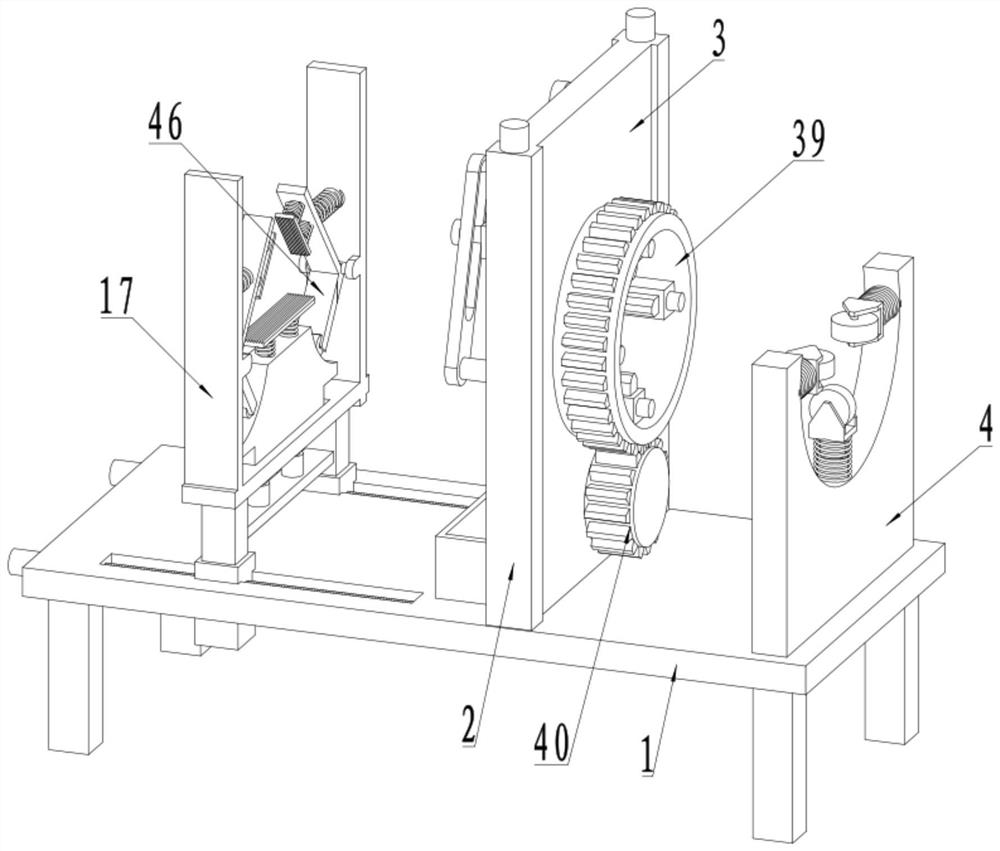

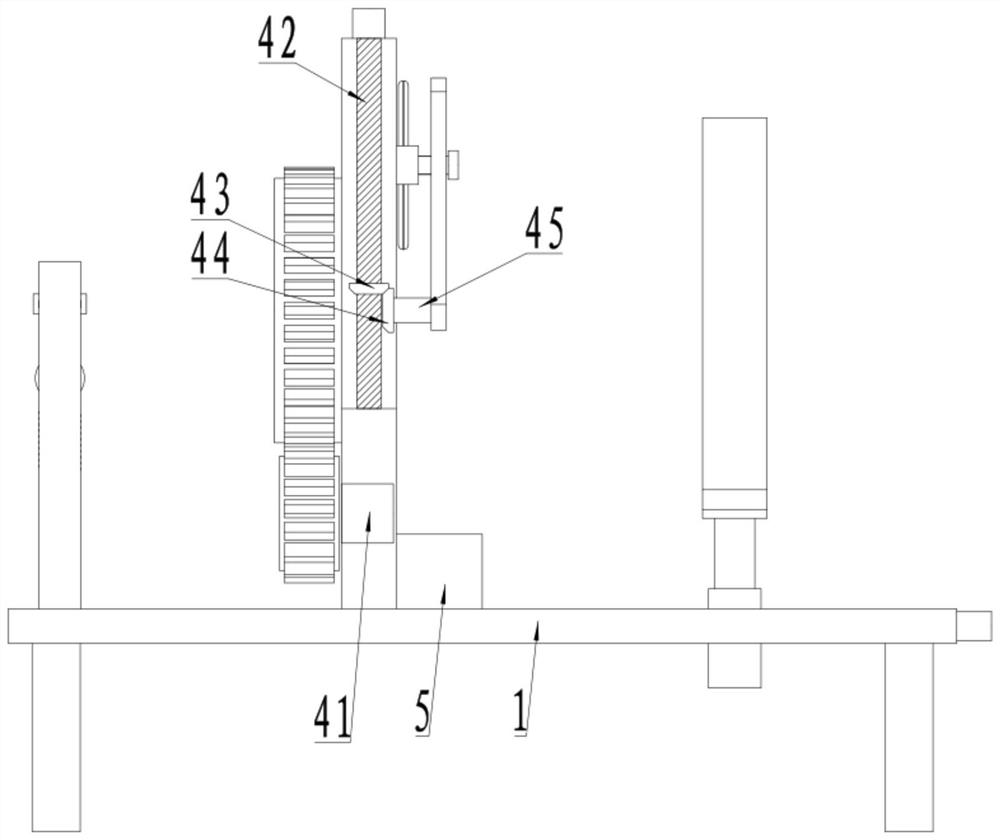

[0022] see Figure 1-4 , a wood cutting and polishing device for gardens, comprising a base plate 1, the four corners of the bottom of the base plate 1 are fixedly connected to support legs 10, the base plate 1 is fixedly connected to a first mounting plate 3, and the first mounting plate 3 is provided with an installation port 33 The first mounting plate 3 on one side of the installation port 33 is rotationally connected to the mounting gear ring 39, and the side wall of the first mounting plate 3 below the mounting gear ring 39 is rotationally connected to the drive gear 40, and the shaft of the drive gear 40 is on one side of the axial direction. The first mounting plate 3 is fixedly connected to the first motor 41, the output shaft of the first motor 41 is fixedly connected to the rotating shaft of the drive gear 40, and the drive gear 40 is meshed with the installation gear ring 39 for transmission connection. The polishing device 32 is provided, and the polishing device ...

Embodiment 2

[0029] see Figure 1-4 The other content of this embodiment is the same as that of Embodiment 1, except that: the bottom of the first mounting plate 3 below the cutting disc 30 is fixedly connected to the receiving groove 5 .

[0030] During the implementation of the present invention, wood is manually placed on the supporting rollers 36 on the second mounting plate 4, and under the action of the supporting rollers 36, the wood is slid forward and passed through the mounting opening 33 on the first mounting plate 3, Extend between the clamping plates 23 between the coaming plates 2, start the hydraulic telescopic column 13 to drive the support block 16 to move upward, and the arc of the rotating wheel 18 on the first rotating plate 46 on both sides of the support block 16 on the support block 16 The first rotating plate 46 rotates to drive the second rotating plate 19 to rotate. Under the action of the clamping plate 23, the clamping and fixing operation of the wood is realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com