Rapid wire-drawing forming device for heat sealing cloth

A wire drawing forming and fast technology, applied in the field of waste plastic processing equipment, can solve the problems of low wire drawing efficiency, long drawing time, low cooling efficiency, etc., and achieve the effect of improving ductility, high drawing efficiency and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

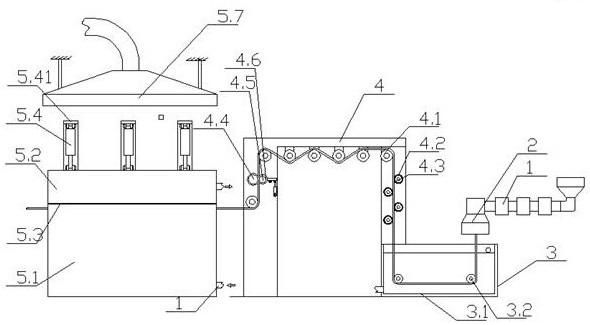

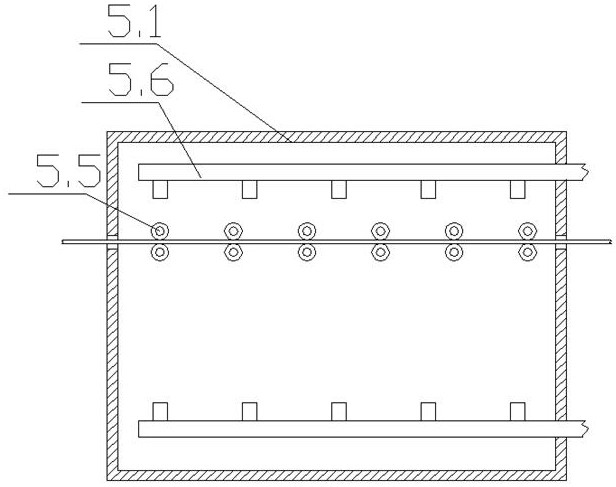

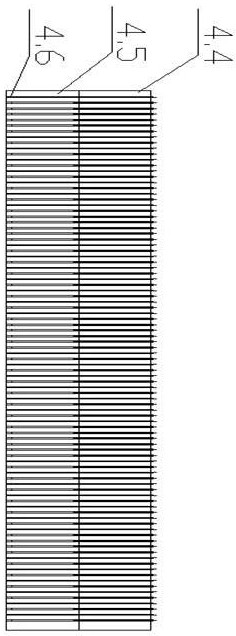

[0011] Now in conjunction with accompanying drawing, the present invention is further elaborated.

[0012] Such as Figure 1-3 As shown, a rapid wire-drawing forming device for heat-sealing cloth includes a melt extrusion device 1, a film forming die 2, a rapid cooling mechanism 3, a film cutting mechanism 4 and a high-speed wire drawing mechanism 5, wherein the end of the melt extrusion device 1 is fixed There is a film forming die 2 and the film forming die 2 is communicated with the melt extrusion device 1, and the masterbatch is melted to form a melt, the melt extrusion device 1 and the film forming die 2 are both prior art, and the melt passes through the film forming die 2 Form a film and fall into the rapid cooling mechanism 3; the rapid cooling mechanism 3 is a cooling water tank 3.1, and a roller 3.2 is fixed through a bearing in the cooling water tank 3.1, and the film is wound on the roller 3.2, and the newly formed Film curing; a film cutting mechanism 4 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com