Automatic film tearing and pasting machine for 3C large sheet materials

A film sticking and film machine technology, which is applied in the field of 3C large sheet automatic tearing film and film sticking machine, can solve the problems of unable to meet the product accuracy requirements of shipping demand, unable to meet large-scale continuous operation, poor film tearing or lamination effect, etc. , to achieve the effect of fast and fast startup, avoiding human error and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in further detail below in conjunction with the accompanying drawings. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

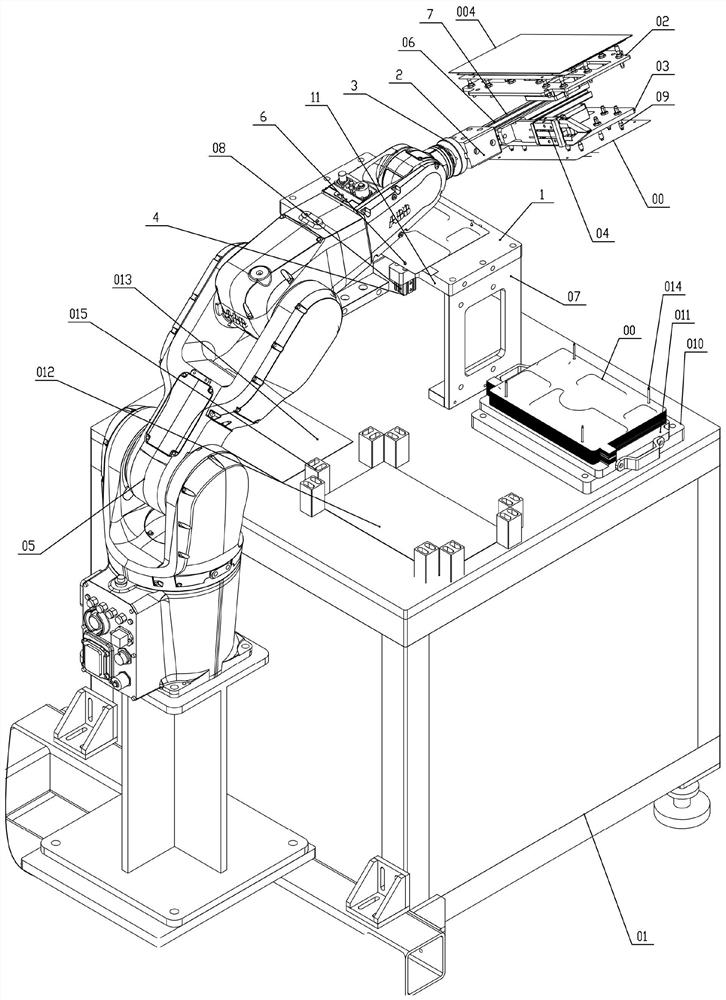

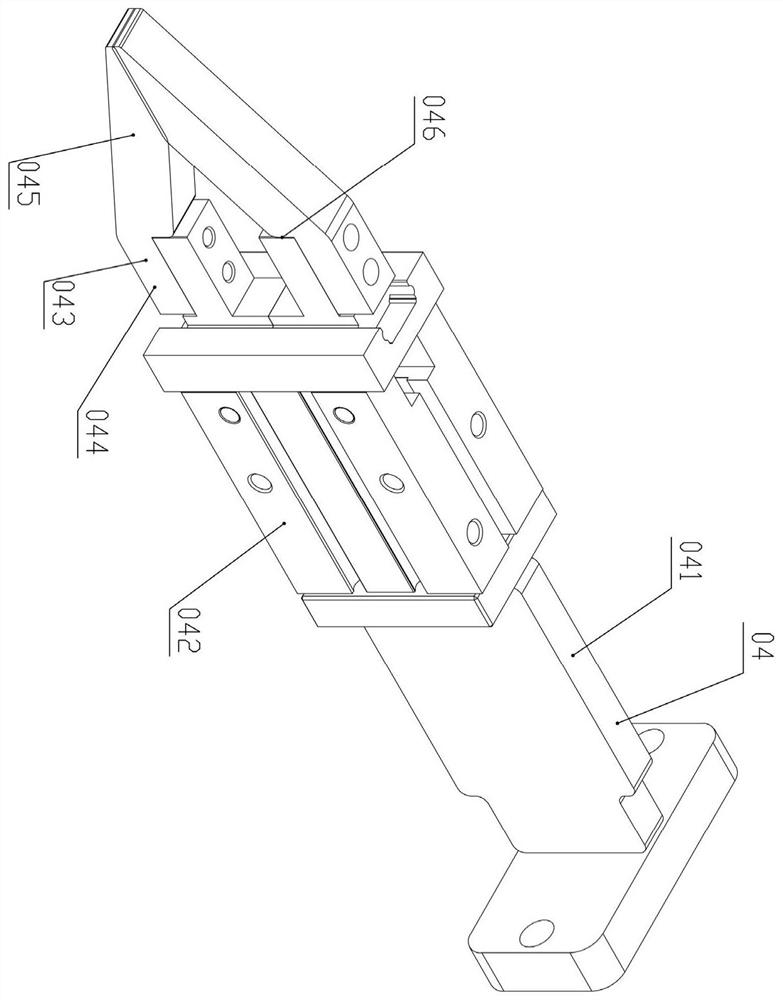

[0050] Figure 1 to Figure 14 Schematically shows a 3C large sheet automatic film tearing and laminating machine according to an embodiment of the present invention. As shown in the figure, the device includes a workbench 01, an upper suction fixture 02, a lower suction fixture 03, a film tearing jaw 04 and an external beam 06, and a manipulator 05 is independently installed directly behind the workbench 01;

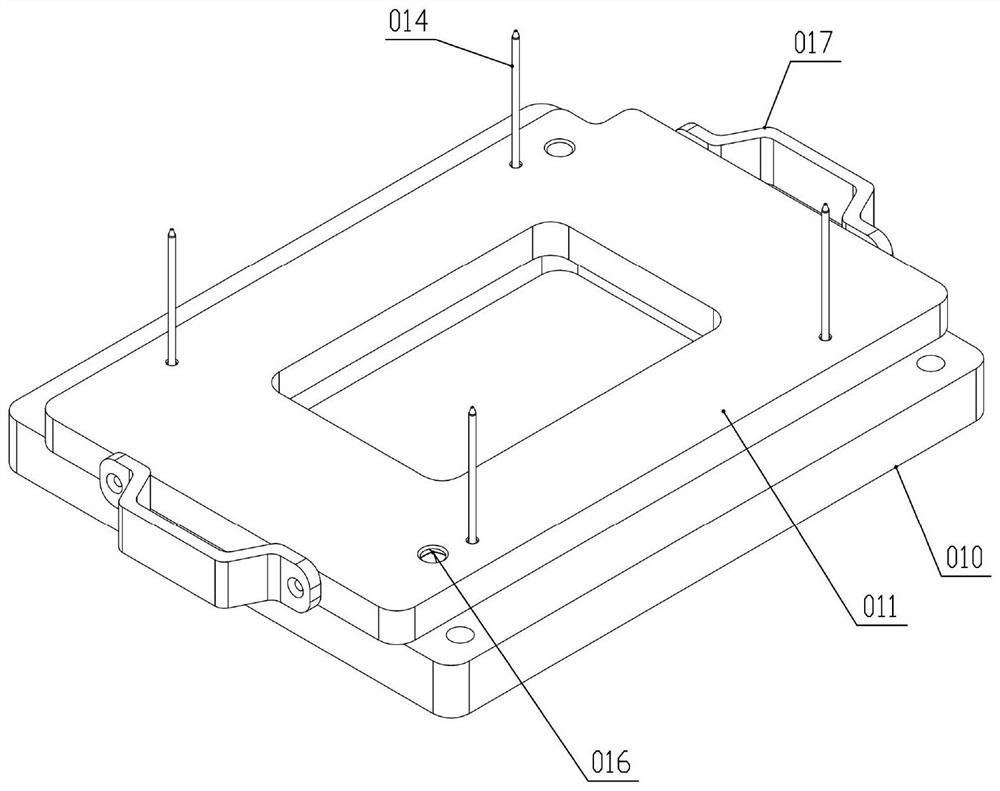

[0051] There is a product table 010 on the right side of the front end of the workbench 01. A material clip 011 is detachably connected to the product table 01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com