Automatic storage mechanism of glass fiber fabric production line

A production line and glass fiber cloth technology, which is applied in the field of automatic storage and storage mechanisms, can solve the problems of glass fiber cloth being difficult to remove, and achieve the effects of high work efficiency, easy storage and labor saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

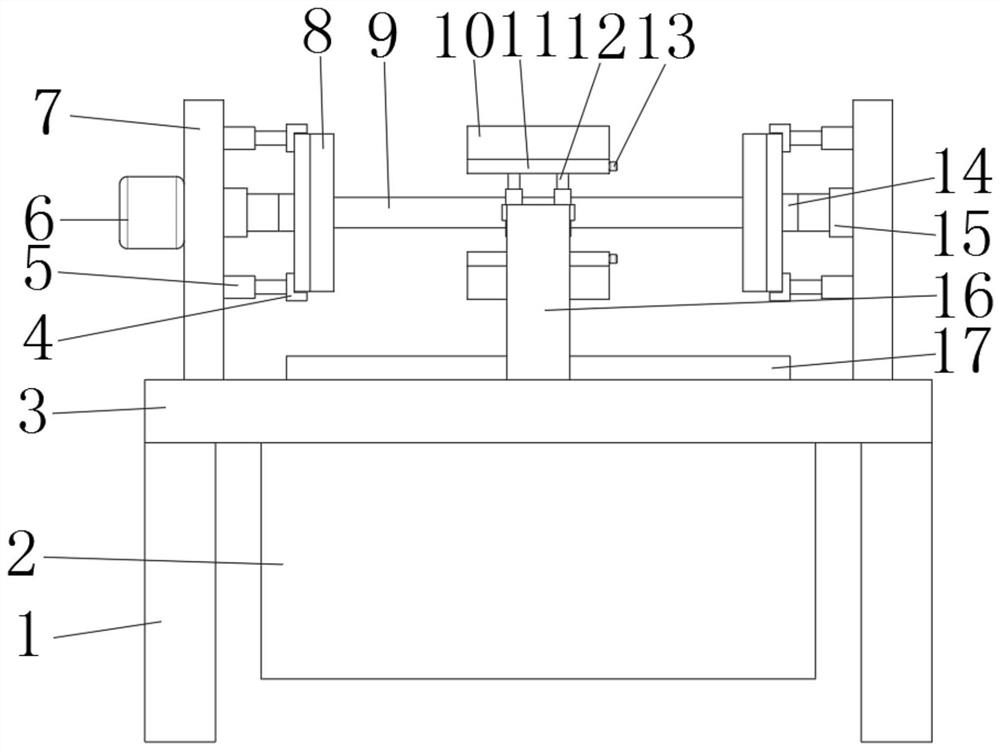

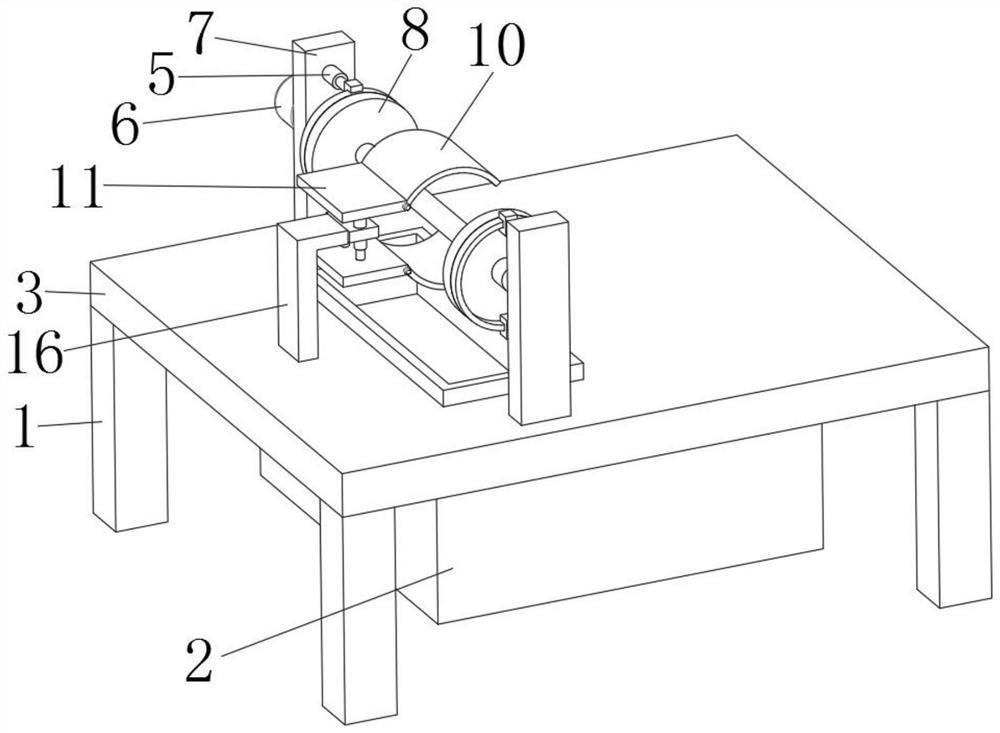

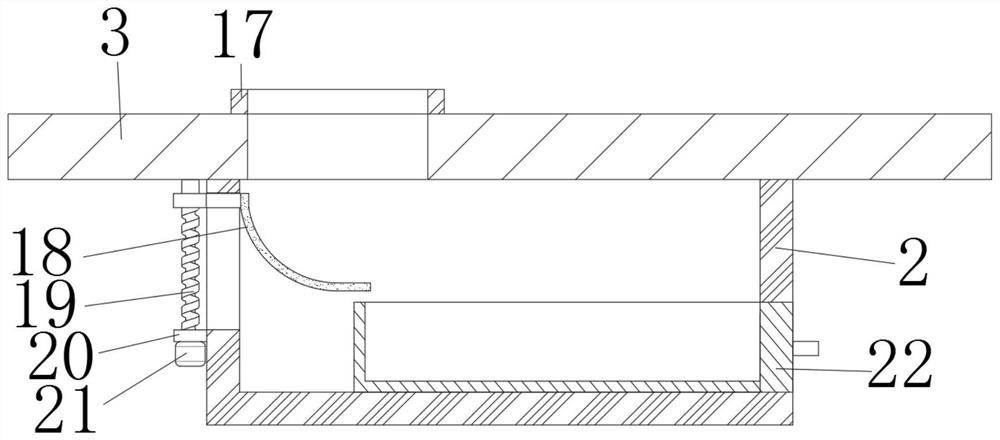

[0029] refer to Figure 1-4 , an automatic storage mechanism for a glass fiber cloth production line, including a workbench 3, the top outer wall of the workbench 3 is fixed with two support plates 7 symmetrically distributed by screws, and the opposite side inner walls of the support plate 7 are elastically fixed by screws Telescopic rod 15, the top of elastic telescopic rod 15 is fixed with fixed rod 14 by screw, and the opposite side outer wall of fixed rod 14 is fixed with disc 8 by screw, and the opposite side inner wall of disc 8 has mounting hole, and the mounting hole The inner wall is plugged with a roller shaft 9, and the opposite side outer wall of the support plate 7 is fixed with a symmetrically distributed first electric telescopic rod 5 by screws, and the top of the first electric telescopic rod 5 is fixed with a slider 4 by screws, and the disc 8 The outer wall on the opposite side is fixed with a slide rail by screws, and the slider 4 is slidably connected to ...

Embodiment 2

[0040] refer to Figure 4 , an automatic storage mechanism for a glass fiber cloth production line, including a workbench 3, the top outer wall of the workbench 3 is fixed with two support plates 7 symmetrically distributed by screws, and the opposite side inner walls of the support plate 7 are elastically fixed by screws Telescopic rod 15, the top of elastic telescopic rod 15 is fixed with fixed rod 14 by screw, and the opposite side outer wall of fixed rod 14 is fixed with disc 8 by screw, and the opposite side inner wall of disc 8 has mounting hole, and the mounting hole The inner wall is plugged with a roller shaft 9, and the opposite side outer wall of the support plate 7 is fixed with a symmetrically distributed first electric telescopic rod 5 by screws, and the top of the first electric telescopic rod 5 is fixed with a slider 4 by screws, and the disc 8 The outer wall on the opposite side is fixed with a slide rail by screws, and the slider 4 is slidably connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com