Detection winding device for washing machine motor coil

A technology of winding device and washing machine, which is applied in the directions of transportation and packaging, transportation of filamentous materials, and thin material processing, etc., can solve the problems such as damage to the paint of enameled wires, affecting product quality, uneven winding, etc., to ensure quality, Good fixation effect and the effect of improving the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

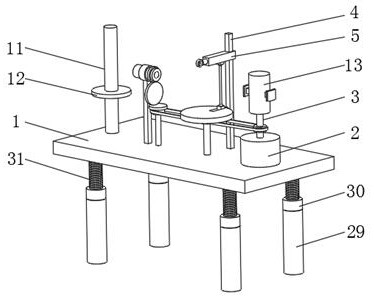

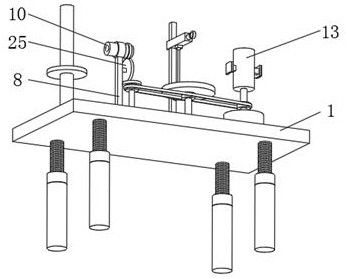

[0039] Example: Reference Figure 1-8 A detection and winding device for washing machine motor coils shown includes a worktable 1, which can be any table structure in the prior art, such as a metal table.

[0040] A winding motor 2 is fixedly installed on the top side of the workbench 1, and the winding motor 2 may be any motor in the prior art, which is screwed to the top side of the workbench 1 for fixing.

[0041] The output end of the winding motor 2 is drivingly connected with a motor shaft 3, the motor shaft 3 can be any metal shaft in the prior art, and it is drivingly connected with the output end of the winding motor 2 through a shaft coupling.

[0042] The top of the motor shaft 3 is fixed with a fixed part, and the top side of the workbench 1 is fixedly equipped with a first vertical rod 4 and a second vertical rod 8, and the first vertical rod 4 and the second vertical rod 8 can be Any kind of metal vertical rod.

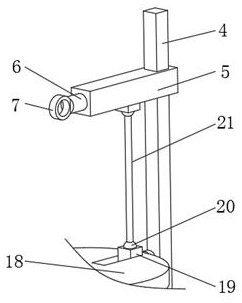

[0043] The first pole 4 is slidingly sleeved wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com