A method for producing l-lactic acid by utilizing lignocellulose simultaneous saccharification and fermentation

A simultaneous saccharification and fermentation, lignocellulose technology, applied in the field of fermentation engineering, can solve the problems of inconsistent fermentation temperature, environmental pollution process, high production cost, etc., achieve the effect of low cost, prolong fermentation time and increase yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

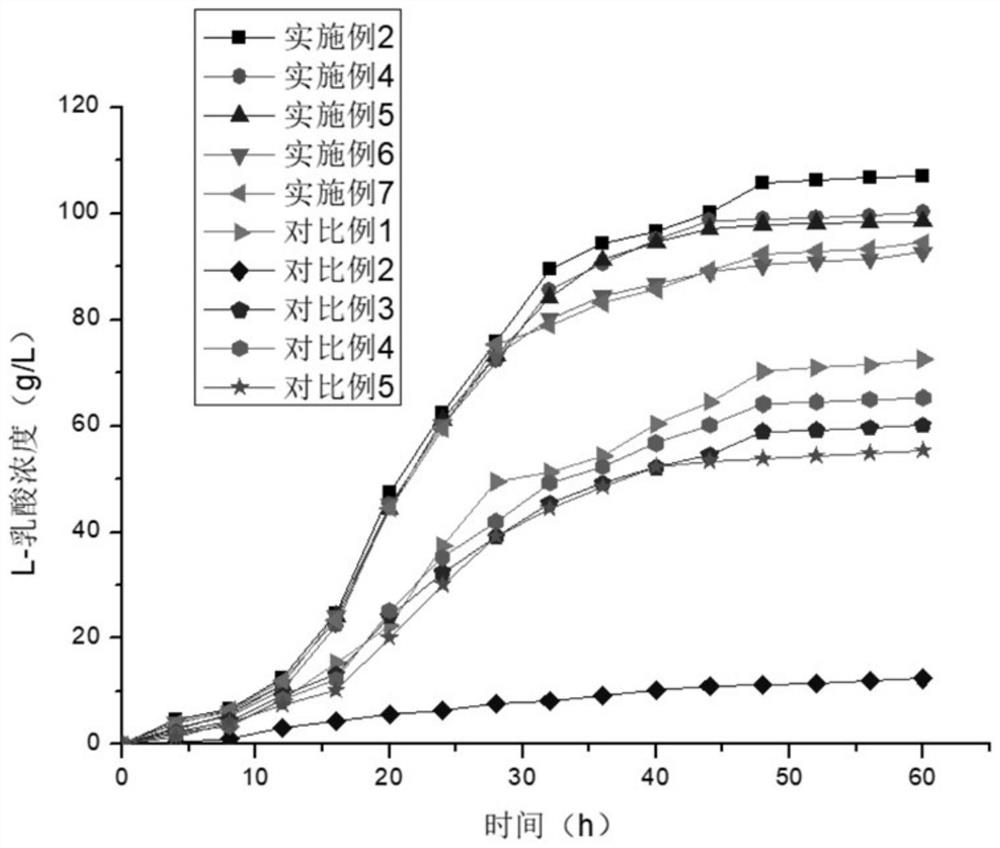

Image

Examples

Embodiment 1

[0034] (1) Bacillus coagulans fermented seed liquid culture: inoculate Bacillus coagulans on a medium plate, place it in a 45°C constant temperature incubator for 12 hours, and connect the grown Bacillus coagulans to the liquid medium, and the culture conditions are temperature 45°C, rotating speed 150rpm, culture time 12h, ventilation rate 1vvm, cultured into Bacillus coagulans seed solution;

[0035] The liquid medium is composed of: glucose 15g / L, yeast powder 5g / L, sodium chloride 2g / L, potassium dihydrogen phosphate 1g / L, magnesium sulfate heptahydrate 0.1g / L, manganese sulfate monohydrate 0.02g / L, Ferrous sulfate heptahydrate 0.01g / L;

[0036] (2) Bacillus stearothermophilus fermentation seed liquid culture: inoculate Bacillus stearothermophilus on a medium plate, place it in a 50°C constant temperature incubator for 12 hours, and connect the grown Bacillus stearothermophilus to the liquid medium medium, the culture conditions are the temperature of 50°C, the rotational...

Embodiment 2

[0042] (1) Bacillus coagulans fermented seed liquid culture: inoculate Bacillus coagulans on a medium plate, place it in a constant temperature incubator at 45°C-55°C for 24 hours, connect the grown Bacillus coagulans to the liquid medium, and cultivate The conditions are that the temperature is 55°C, the rotating speed is 250rpm, the incubation time is 24h, and the ventilation rate is 3vvm, and the seed solution of Bacillus coagulans is cultivated;

[0043] The liquid medium is composed of: glucose 25g / L, yeast powder 12g / L, sodium chloride 4g / L, potassium dihydrogen phosphate 3g / L, magnesium sulfate heptahydrate 0.3g / L, manganese sulfate monohydrate 0.07g / L, Ferrous sulfate heptahydrate 0.02g / L;

[0044] (2) Bacillus stearothermophilus fermentation seed liquid culture: inoculate Bacillus stearothermophilus on a medium plate, place it in a 52°C constant temperature incubator for 24 hours, and connect the grown Bacillus stearothermophilus to the liquid medium medium, the cult...

Embodiment 3

[0050] (1) Bacillus coagulans fermented seed liquid culture: inoculate Bacillus coagulans on a medium plate, place it in a 50°C constant temperature incubator for 18 hours, connect the grown Bacillus coagulans to the liquid medium, and the culture conditions are temperature 50°C, rotating speed 200rpm, culture time 18h, ventilation rate 3vvm, cultured into Bacillus coagulans seed solution;

[0051] The liquid medium is composed of: glucose 20g / L, yeast powder 7g / L, sodium chloride 3g / L, potassium dihydrogen phosphate 2g / L, magnesium sulfate heptahydrate 0.2g / L, manganese sulfate monohydrate 0.05g / L, Ferrous sulfate heptahydrate 0.015g / L;

[0052] (2) Bacillus stearothermophilus fermentation seed liquid culture: inoculate Bacillus stearothermophilus on a medium plate, place it in a 55°C constant temperature incubator for 18 hours, and connect the grown Bacillus stearothermophilus to the liquid medium medium, the culture conditions are temperature 55°C, rotation speed 200rpm, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com