Efficient radiator assembly of automobile

A radiator, high-efficiency technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problem of affecting the heat dissipation efficiency and strength of the radiator assembly, the radiator has no protective structure, and the heat dissipation area of the radiator Small problems, to achieve the effect of improving the cooling effect, improving the heat dissipation effect, and improving the cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

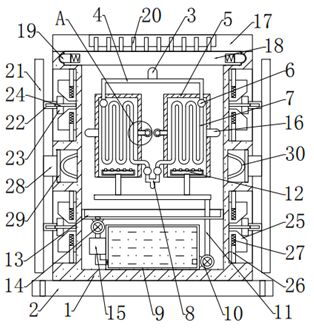

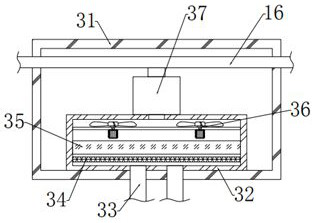

[0026] see Figure 1-4 , in an embodiment of the present invention, an automobile high-efficiency radiator assembly includes a housing 1, and a water inlet pipe 3 is fixedly connected to the housing 1, and the water inlet pipe 3 is connected to the housing 1 through a water guide pipe 4. The heat dissipation mechanism at the left and right ends of the inner side is connected, the output end of the heat dissipation mechanism is connected with the water outlet pipe 8 , and a protection mechanism is arranged on the outer side of the housing 1 .

Embodiment 2

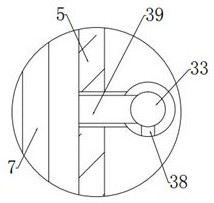

[0028] In this embodiment, the heat dissipation mechanism includes a heat dissipation box 5 fixedly connected to the inner side of the housing 1, and a fixed pipe 6 is fixedly connected to the inner side of the heat dissipation box 5, and the top end of the fixed pipe 6 is connected to the water guide pipe 4. The bottom of the fixed pipe 6 is fixedly connected with a number of heat dissipation pipes 7, the output ends of the heat dissipation pipes 7 are connected to the water outlet pipe 8, and the lower side of the heat dissipation pipe 7 is provided with a spraying mechanism. Splitting the flow not only improves the cooling efficiency, but also improves the cooling effect. By arranging a plurality of heat dissipation pipes 7, the heat dissipation area of the device can be increased, and the heat dissipation efficiency of the device can be further improved.

[0029] In this embodiment, the heat dissipation pipe 7 is a serpentine bend.

[0030] In this embodiment, the spray ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com