Orthotropic steel bridge deck fatigue crack detection equipment and use method thereof

A technology for steel bridge decks and fatigue cracks, applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve problems affecting ultrasonic detection accuracy, small manipulation space, and detection efficiency low level problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

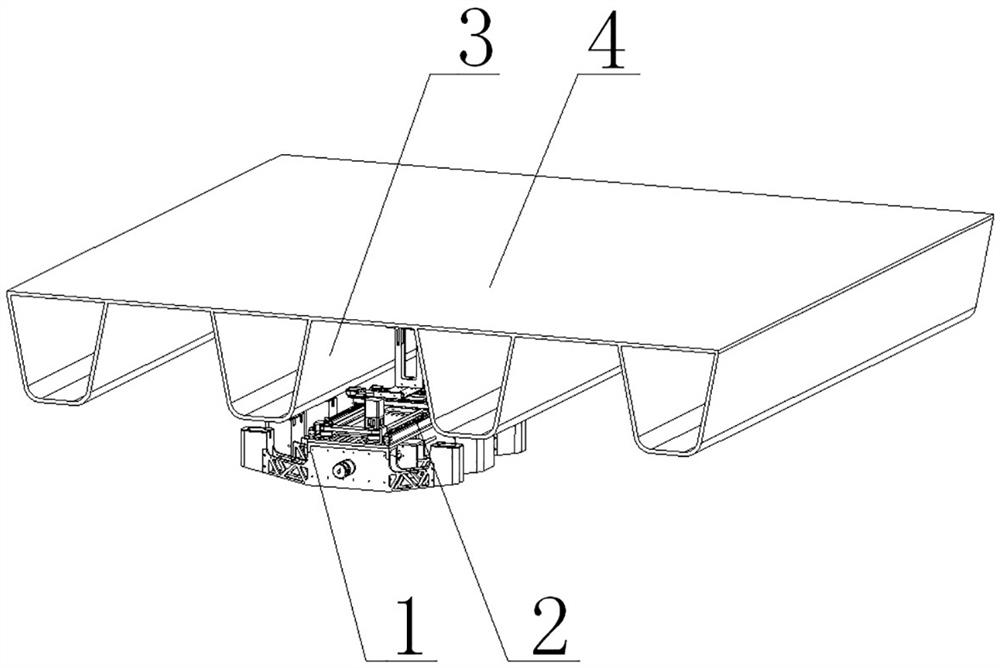

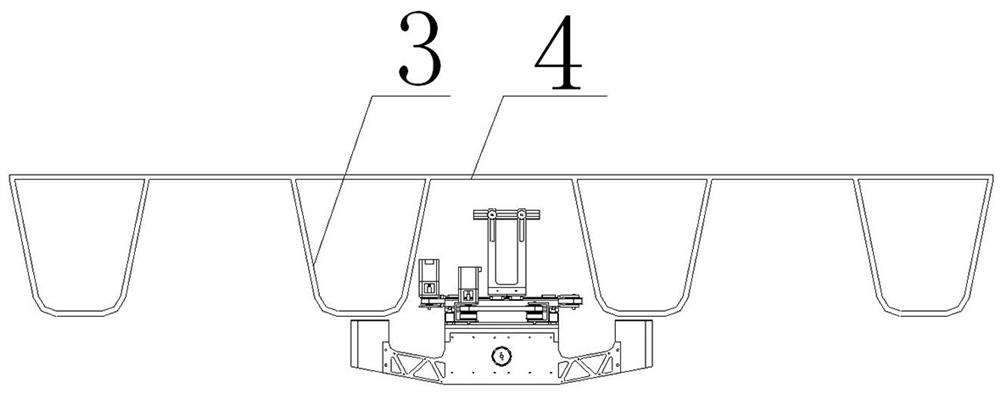

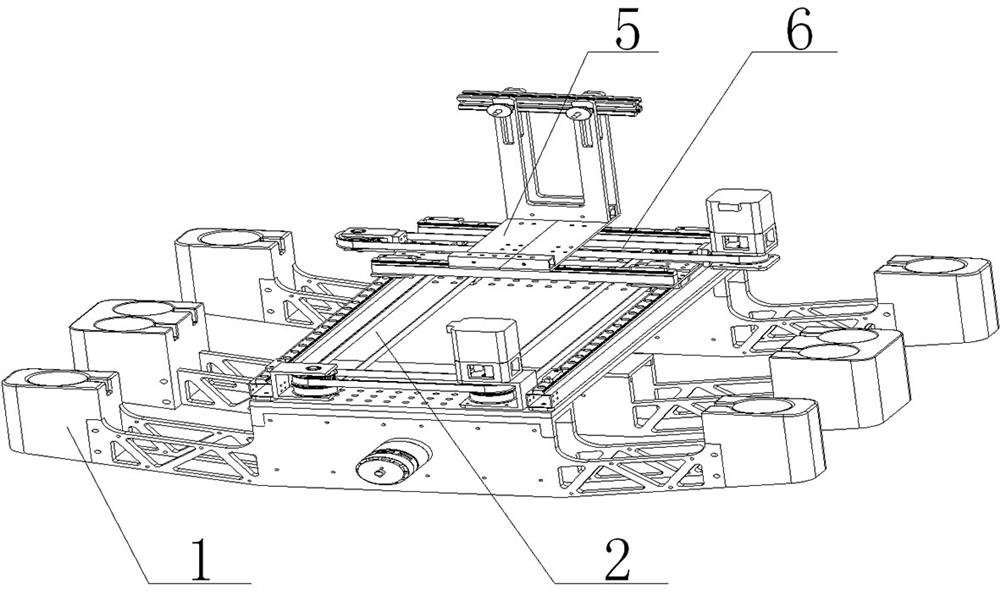

[0056] Such as Figures 1 to 14 As shown, the present invention is an orthogonal opposite steel bridge panel fatigue crack detection equipment, including walking assembly 1 and a detection platform assembly 2, the walking assembly 1 including an active travel mechanism 45, a passive travel mechanism 49, and a third drive mechanism 44. The active traveling mechanism 45 and the passive travel mechanism 49 are both a curved structure, and the active travel mechanism 45 and the top of the passive travel mechanism 49 are provided with an electromagnet 46, and the transmission shaft 48 of the third drive mechanism 44 runs through passive. After the traveling mechanism 49 is threaded with the active traveling mechanism 45, when the third drive mechanism 44 is rotated by the drive shaft 48, the active traveling mechanism 45 can be close or away from the passive travel mechanism 49;

[0057] The detection platform assembly 2 includes a first support plate 14, a track square pipe 12, a first...

Embodiment 2

[0061] Based on the first embodiment, the passive travel mechanism 49 is two, and the active travel mechanism 45 is located between the two passive travel mechanisms 49; the active travel mechanism 45 and the passive travel mechanism 49 each include a fixed plate 52, two The connecting arm 50 and the two fixing heads 51 are both a hollow structure, and the two connecting arm 50 are connected to both sides of the fixing plate 52, and the other end is connected to the fixed head 51, the overall arc Structure, the electromagnet 46 is located at the top of the fixed head 51, and the first support plate 14 of the detecting platform assembly 2 is located at the top of each fixing plate 52; the third drive mechanism 44 is located in one of the passive walking mechanisms 49. On the sidewall, the drive shaft 48 of the third drive mechanism 44 sequentially penetrates the retention plate 52 of the active travel mechanism 45 and the passive travel mechanism 49, and the fixing plate 52 of the ...

Embodiment 3

[0063] On the basis of Example 2, the top portion of the rail square tube 12 is also provided with a first slide rail 42, and a first slider 16 having a match thereof, a first slider 16 It is possible to slide in the first sliding rail 42 in the first slide 42, and the top of the first slider 16 is connected to the bottom of the second support plate 17.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com