Cable sheath cutting device

A cutting device and cable sheath technology, which is applied in the direction of cable installation device, cable installation, dismantling/armored cable equipment, etc., can solve the problems of difficult automatic adjustment of the cable sheath cutting tool and the low degree of automation of the cable sheath, and achieve convenience The effect of collecting and sorting, saving labor costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

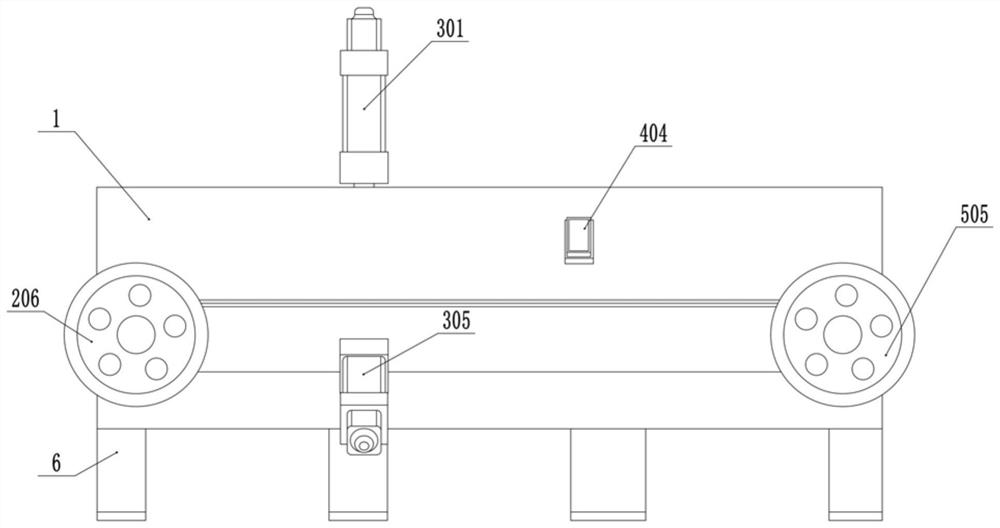

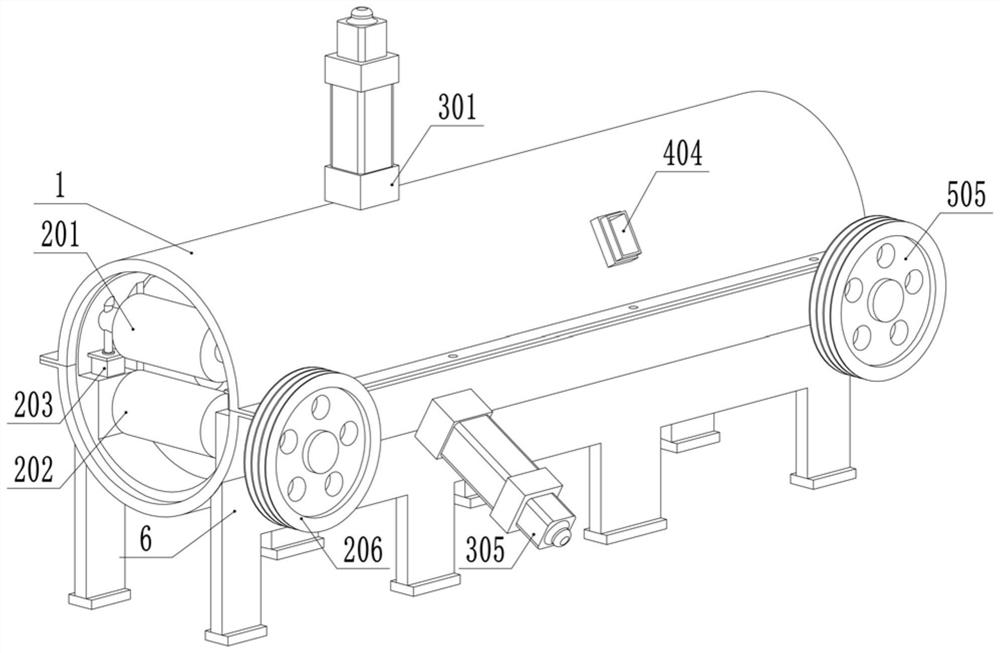

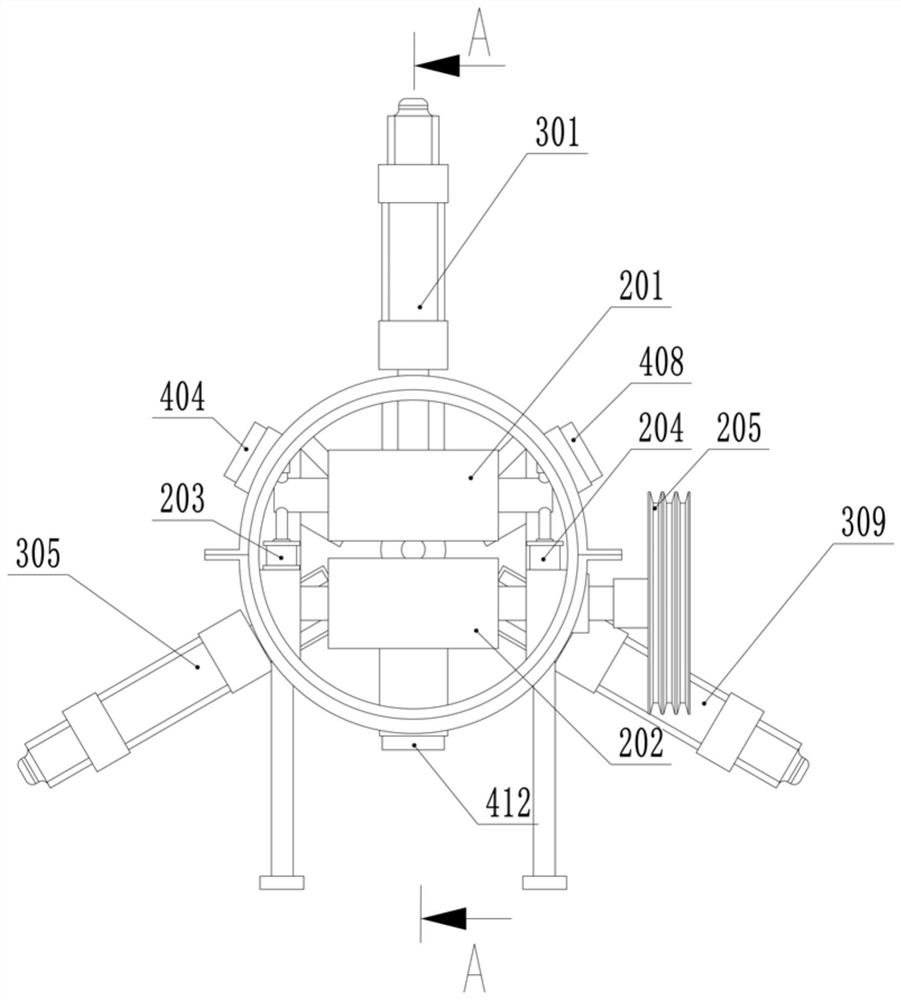

[0030] like Figure 1-Figure 9As shown, the present invention provides a cable sheath cutting device, comprising a feeding mechanism I, a cutting mechanism II, a stripping mechanism III, a discharging mechanism IV and a supporting structure V. The feeding mechanism 1 includes a feeding ring 2 arranged at the front of the cable sheath cutting device. The feeding ring 2 is provided with an upper feeding roller 201 and a lower feeding roller 202, and the distance between the upper feeding roller 201 and the lower feeding roller 202 can pass through. The first feeding regulating motor 203 and the second feeding regulating motor 204 arranged on both sides of the roller are adjusted, and the lower feeding roller 202 is connected to the first V pulley 205 through the connecting shaft. The cutting mechanism II includes a cutting ring 3 arranged at the front of the cable sheath cutting device, along the cutting ring 3 are installed a first telescopic electric cylinder 301 , a second te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com