Conductive film and conductive film roll, electronic paper, touch panel, and flat panel display using same

一种导电性薄膜、导电性金属的技术,应用在绝缘载体上的导电层、仪器、非线性光学等方向,能够解决导电性降低、金属细线剥离等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0114] An object of the first embodiment is to provide a conductive film, a conductive film roll, electronic paper, a touch panel, and a flat panel display that sufficiently maintain transparency and are excellent in both conductivity and flexibility.

[0115] [First Embodiment: Conductive Film]

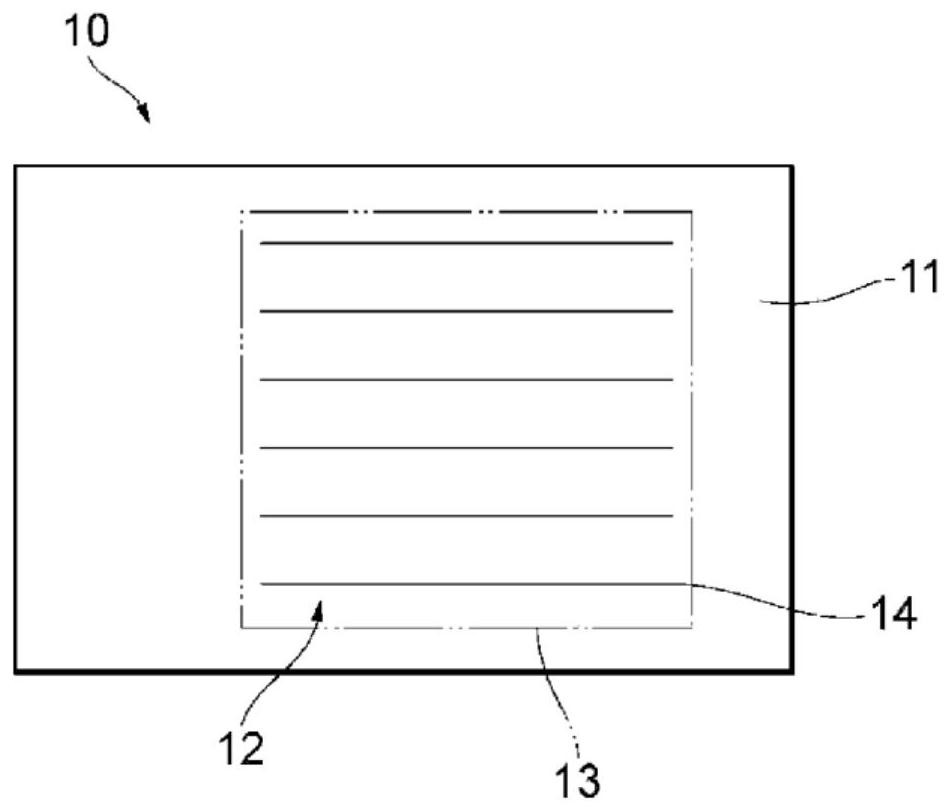

[0116] The conductive film according to the first embodiment is a conductive film having a transparent substrate and a conductive portion including a metal thin wire pattern arranged on one or both surfaces of the transparent substrate. The thin metal wire pattern is composed of thin metal wires, the thin metal wires contain conductive metal atoms M and silicon atoms Si, and in the STEM-EDX analysis of the cross-section of the thin metal wires perpendicular to the direction in which the thin metal wires extend, the When the maximum thickness of the thin metal wire is expressed as T, the atomic % ratio Si / M of the silicon atom Si to the conductive metal atom M in the thickness region ...

no. 2 approach

[0198] An object of the second embodiment is to provide a conductive film exhibiting more excellent transparency, and a conductive film roll, electronic paper, touch panel, and flat panel display using the same.

[0199] [Second Embodiment: Conductive Film]

[0200] The conductive film according to the second embodiment is characterized in that it is a conductive film having a transparent base material and a conductive portion including a thin metal wire pattern arranged on one or both sides of the transparent base material, and the thin metal wire pattern is composed of The thin metal wire is composed of conductive metal atoms M and oxygen atoms O. In the STEM-EDX analysis of the cross section of the thin metal wire perpendicular to the extending direction of the thin metal wire, the fine metal wire When the thickness of is denoted as T, the atomic % ratio O / M of the aforementioned oxygen atoms O to the aforementioned conductive metal atoms M in the thickness region from 0.10...

no. 3 approach

[0300] An object of the third embodiment is to provide a conductive film having both high conductivity and high adhesion between a transparent substrate and thin metal wires, and a conductive film roll, electronic paper, touch panel, and flat panel display using the same.

[0301] [Third Embodiment: Conductive Film]

[0302] The conductive film according to the third embodiment is characterized in that it has a transparent base material and a conductive portion including a thin metal wire pattern arranged on one or both sides of the transparent base material. The thin metal wire pattern is composed of thin metal wires containing conductive metal atoms M and carbon atoms C, in the STEM-EDX analysis of the cross section of the thin metal wires perpendicular to the direction in which the thin metal wires extend , when the thickness of the aforementioned thin metal wire is denoted as T, the atomic % ratio C / M in the thickness range from 0.10T to 0.25T from the interface of the thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

| hazing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com