A kind of preparation method of Maduro cigar wrapper

A technology for cigar wrappers and wrappers, which is applied to the production field of Maduro cigar wrappers, can solve the problems of insufficient color and smell of tobacco leaves, not maximizing profits, and different degrees of fermentation of tobacco leaves, so as to achieve enhanced aroma of tobacco leaves, Avoid uncontrollable and fermentation failure, which is beneficial to large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

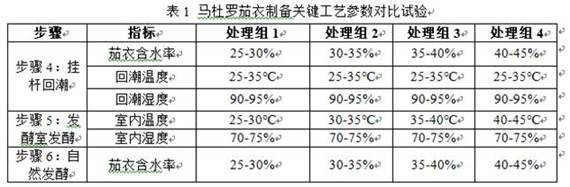

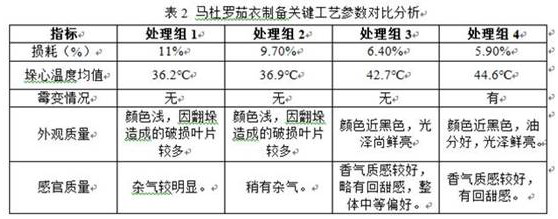

Method used

Image

Examples

Embodiment 1

[0045] A preparation method of Maduro wrapper, the concrete process is as follows:

[0046] Step 1: Select the wrapper, select the wrapper with a length of 45-55cm, a width of ≥10cm, and a single tobacco leaf weight of 7-10g as the raw material; tobacco leaves with similar size and quality are conducive to the same treatment in the follow-up, and the wrapper produced The color and quality are more uniform; the mixture of rose petals and tobacco leaves is selected as the material for wrapper preparation, and the mass ratio of tobacco leaves and rose petals is 100:1.

[0047] Step 2: low-temperature insecticidal, put the selected wrapper material in step 1 into a cold storage, and freeze for 10 days at a temperature of minus 12° C. to destroy and kill tobacco eggs and adults.

[0048] Step 3: Dip the stalk, thaw the frozen wrapper in step 2, and then enter the stalk dipping process to increase the moisture content of the petiole, and conduct through the veins to increase the moi...

Embodiment 2

[0059] A preparation method of Maduro wrapper, the concrete process is as follows:

[0060] Step 1: Select the wrapper, select the wrapper with a length of 45-55cm, a width of ≥10cm, and a single tobacco leaf weight of 7-10g as the raw material; tobacco leaves with similar size and quality are conducive to the same treatment in the follow-up, and the wrapper produced The color and quality are more uniform, and the mixture of mint leaves and tobacco leaves is selected as the material for wrapper preparation, and the mass ratio of tobacco leaves and mint leaves is 100:10.

[0061] Step 2: low temperature insecticidal, put the selected wrapper material in step 1 into a cold storage, the temperature is minus 15 ℃, freeze for 12 days, destroy and kill tobacco eggs and adults.

[0062] Step 3: Dip the stalk, thaw the frozen wrapper in step 2, and then enter the stalk dipping process to increase the moisture content of the petiole, and conduct through the veins to increase the moistu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com