Baby wet wipe and preparation method thereof

A technology for wet wipes and babies, which is applied to cosmetic preparations, medical preparations containing active ingredients, and pharmaceutical formulas, etc., can solve the problems of general moisturizing effect, discomfort, breeding of bacteria, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of wet tissue for baby is made by following steps:

[0041] Step S1: dissolving the antibacterial agent in deionized water, adding glycerin, and stirring for 1 hour at a rotation speed of 300 r / min to obtain the first emulsion;

[0042] Step S2: Add lauryl glucoside, citric acid, and olive oil into the stirring tank, and stir for 1 hour at a rotation speed of 200 r / min to prepare the second emulsion;

[0043] Step S3: After uniformly mixing the first emulsion and the second emulsion, immerse the modified non-woven fabric at a temperature of 40°C for 5 hours, then take out the non-woven fabric until no liquid drips, and obtain Baby wipes.

[0044] Described antibacterial agent is made by following steps:

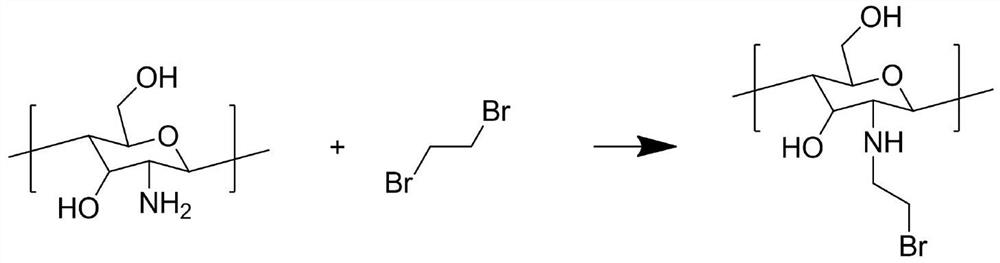

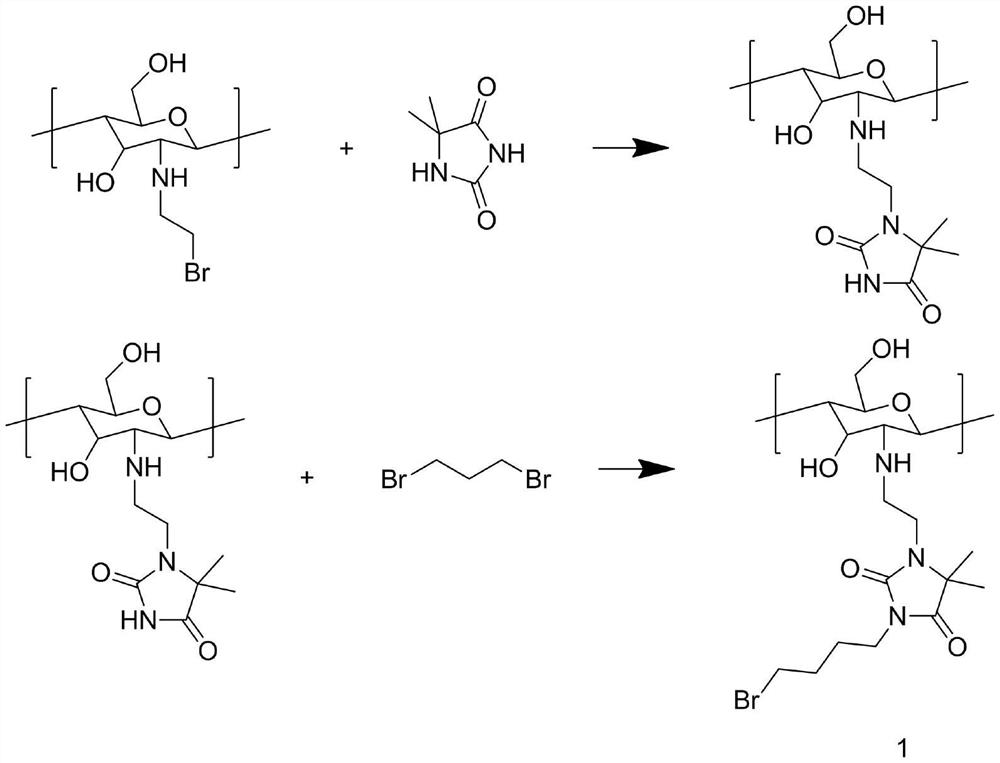

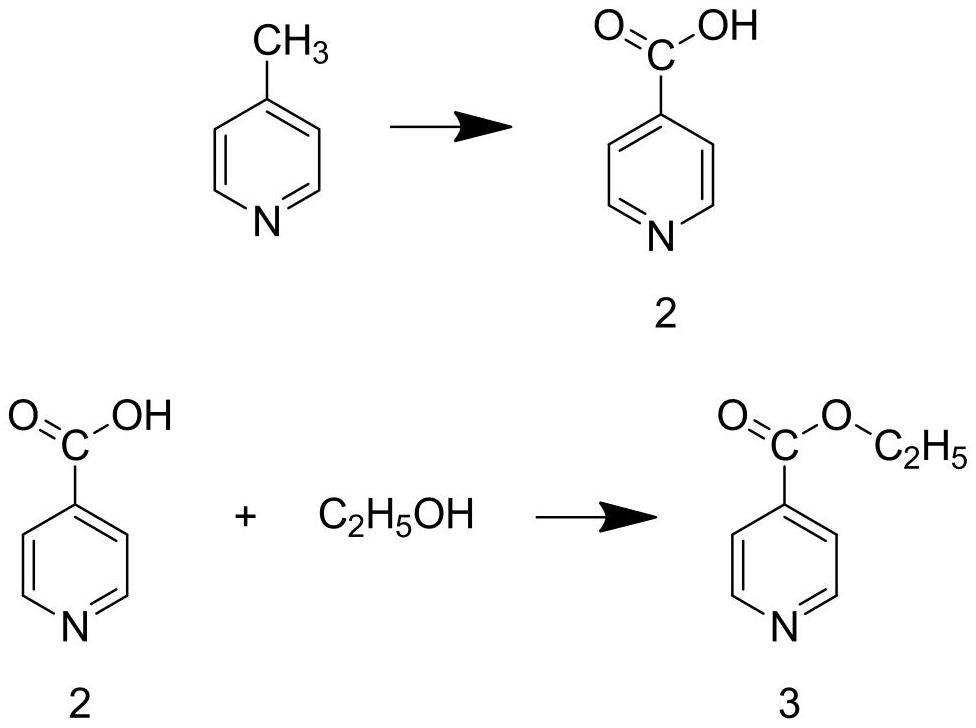

[0045] Step A1: Dissolve chitosan in hydrochloric acid solution, add 1,2-dibromoethane and potassium carbonate, and carry out reflux reaction for 3 hours under the conditions of rotation speed of 150r / min and temperature of 50°C, and then add 5, After continu...

Embodiment 2

[0054] A kind of wet tissue for baby is made by following steps:

[0055] Step S1: dissolving the antibacterial agent in deionized water, adding glycerin, and stirring for 1.5 hours at a rotating speed of 300 r / min to obtain the first emulsion;

[0056] Step S2: Add lauryl glucoside, citric acid, and olive oil into the stirring tank, and stir for 1.5 hours at a rotating speed of 200 r / min to prepare the second emulsion;

[0057] Step S3: After uniformly mixing the first emulsion and the second emulsion, immerse the modified non-woven fabric at a temperature of 40°C for 8 hours, then take out the non-woven fabric until no liquid drips to obtain Baby wipes.

[0058] Described antibacterial agent is made by following steps:

[0059] Step A1: Dissolve chitosan in hydrochloric acid solution, add 1,2-dibromoethane and potassium carbonate, and carry out reflux reaction for 3 hours under the conditions of rotation speed of 150r / min and temperature of 60°C, and then add 5, After 5-d...

Embodiment 3

[0068] A kind of wet tissue for baby is made by following steps:

[0069] Step S1: dissolving the antibacterial agent in deionized water, adding glycerin, and stirring for 1 hour at a rotation speed of 500 r / min to obtain the first emulsion;

[0070] Step S2: Add lauryl glucoside, citric acid, and olive oil into the stirring tank, and stir for 1 hour at a rotation speed of 300 r / min to obtain the second emulsion;

[0071] Step S3: After uniformly mixing the first emulsion and the second emulsion, immerse the modified non-woven fabric, soak for 5 hours at a temperature of 50°C, and take out the non-woven fabric until no liquid drips to obtain Baby wipes.

[0072] Described antibacterial agent is made by following steps:

[0073] Step A1: Dissolve chitosan in hydrochloric acid solution, add 1,2-dibromoethane and potassium carbonate, and carry out reflux reaction for 5 hours under the conditions of rotation speed of 200r / min and temperature of 50°C, and then add 5, After conti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap