Washing tower capable of replacing adsorption liquid medicine based on industrial waste gas impurity filtering mass

A technology for industrial waste gas and liquid adsorption, applied in the field of scrubbers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

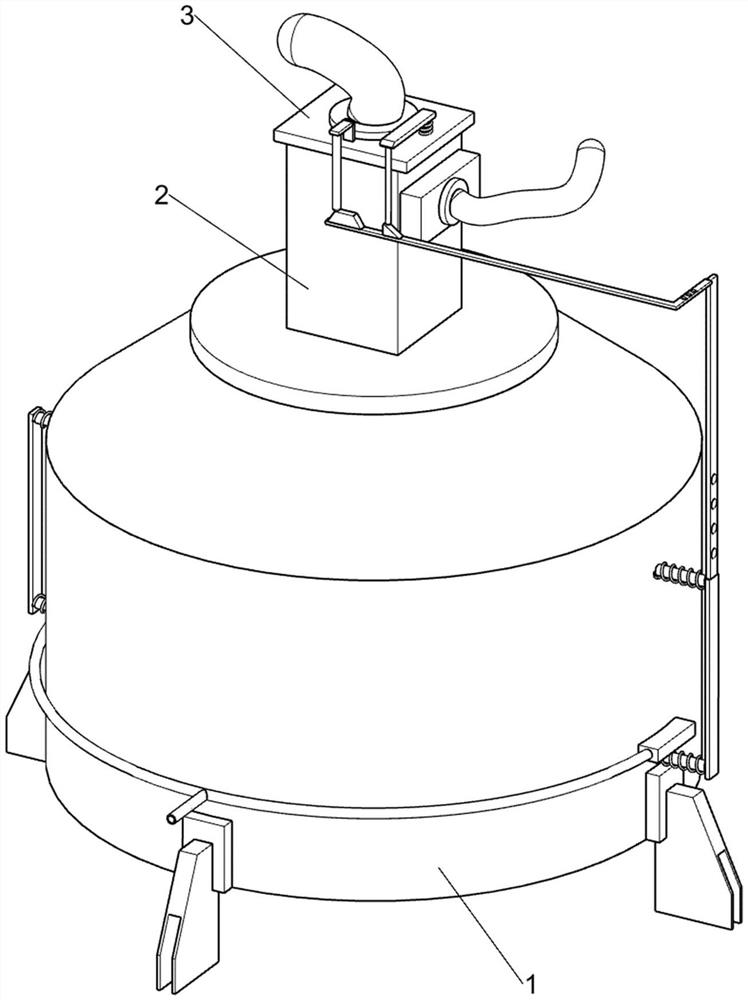

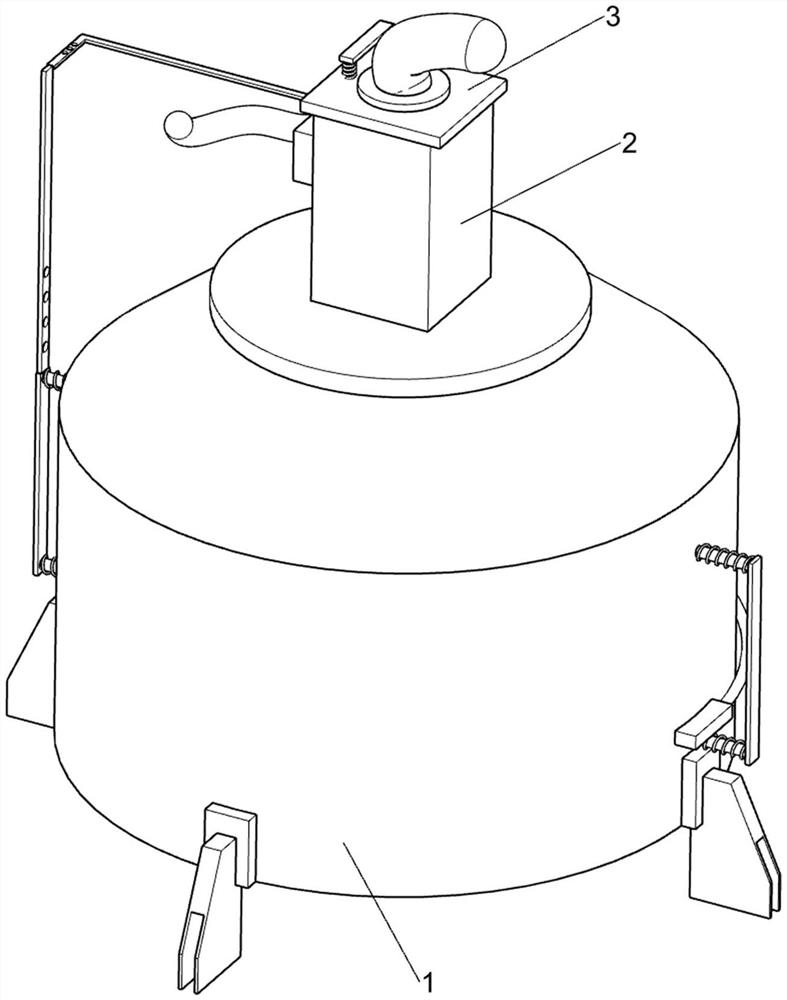

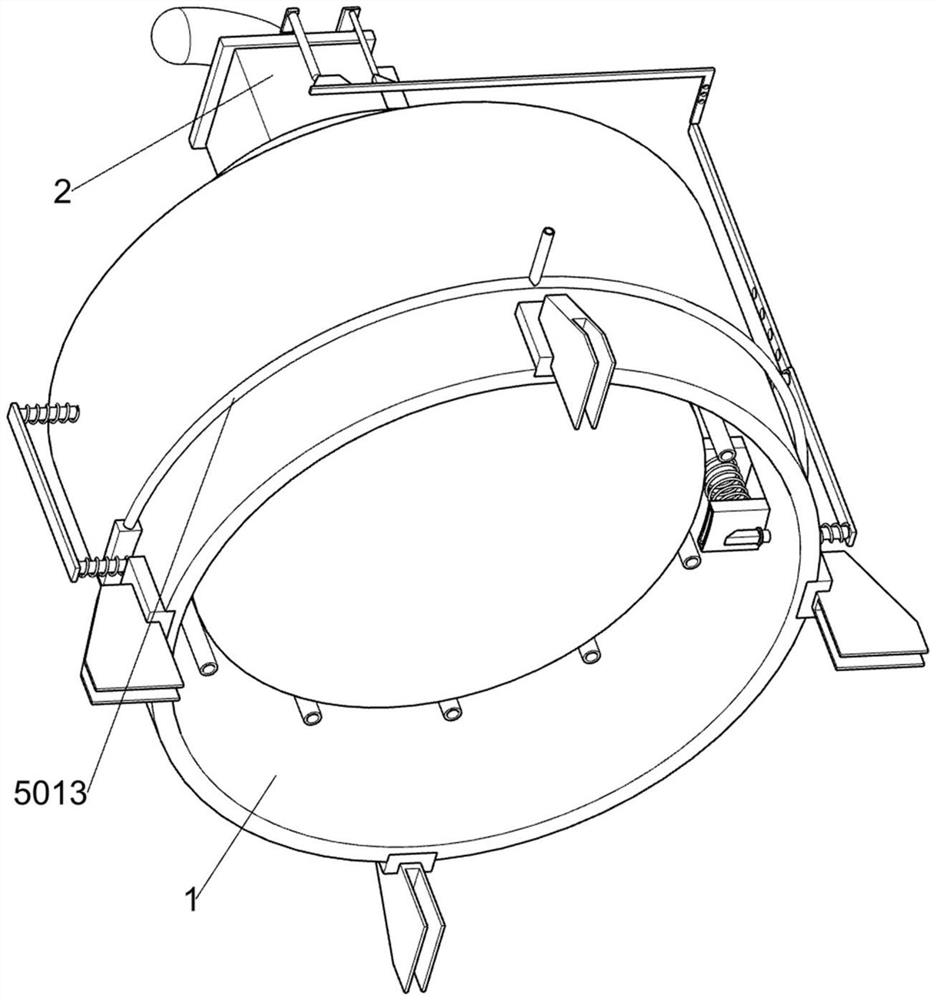

[0025] A washing tower based on filtering industrial waste gas impurities to replace the adsorption liquid, such as Figure 1-8 As shown, it includes a support tower 1, a support frame 2, an air intake partition 3, an industrial exhaust gas washing assembly 4, a waste liquid extraction and replenishment assembly 5, an air intake closure assembly 6 and an airflow guide assembly 7, and the top of the support tower 1 A support frame 2 is installed, and the air intake partition 3 is fixedly connected to the top surface of the support frame 2. An industrial waste gas cleaning component 4 is installed in the support tower 1, and a waste liquid extraction and supply component 5 is slidably connected to the industrial waste gas cleaning component 4. , the waste liquid extraction and supply assembly 5 is used to replace the washing liquid in the washing box, and the air intake closing assembly 6 is arranged on the support frame 2, and the air intake closing assembly 6 is used to realize...

Embodiment 2

[0035] On the basis of Example 1, such as Figure 5 As shown, a filter screen 8 is also included, and a filter screen 8 is fixedly distributed on the upper part of the intake pipe frame 406 away from the washing box 405, and the filter screen 8 is used to block large particles of dirt in the exhaust gas.

[0036] Exhaust gas enters the support frame 2, and the exhaust gas enters the intake pipe frame 406 through the filter screen 8 on the intake pipe frame 406. The filter screen 8 blocks the large particle dirt in the exhaust gas to prevent large particle dirt from entering the intake pipe frame 406. It is difficult for washing liquid to wash it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com