Color steel tile pressing device capable of conveniently cleaning dust on surface of steel plate

A dust and color steel technology, applied in the field of color steel processing equipment, can solve the problems of high labor intensity, extrusion of unqualified products, deviation, etc., to achieve the effect of compact structure, meet production needs, and avoid deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

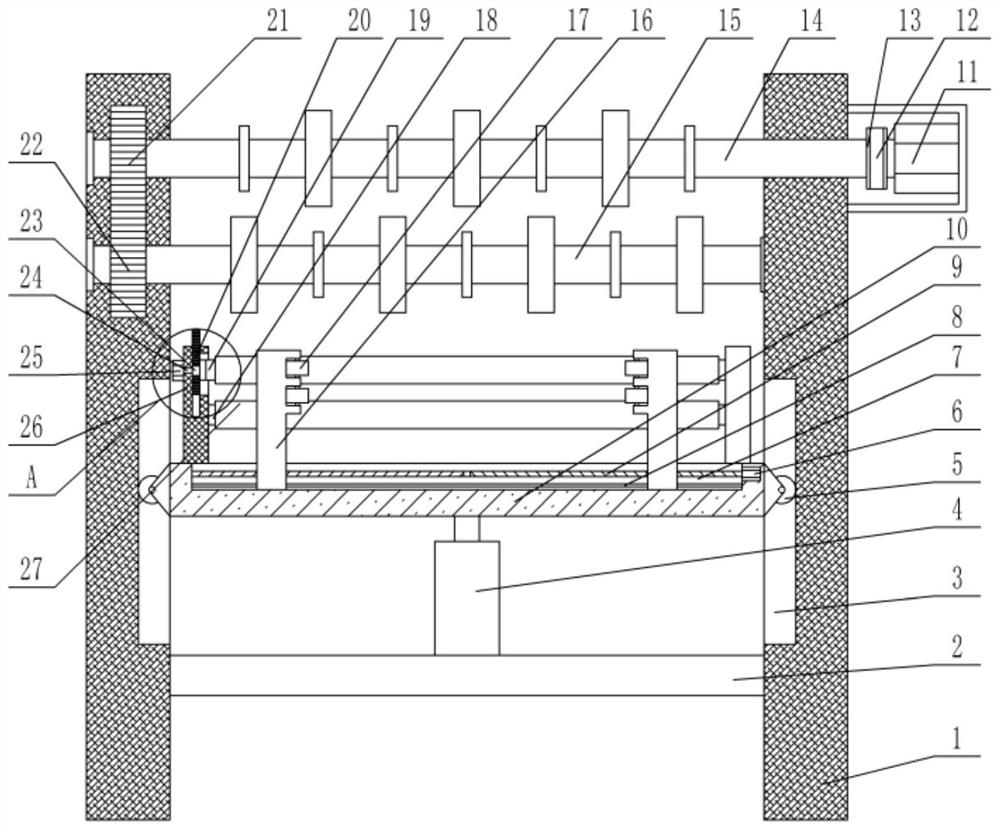

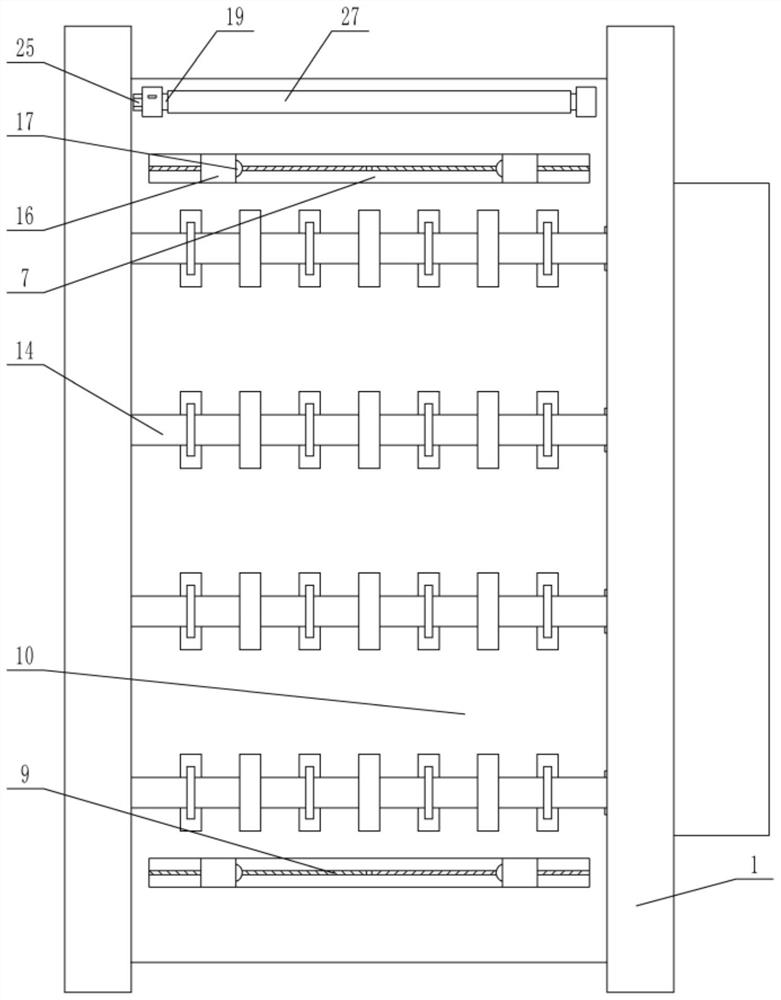

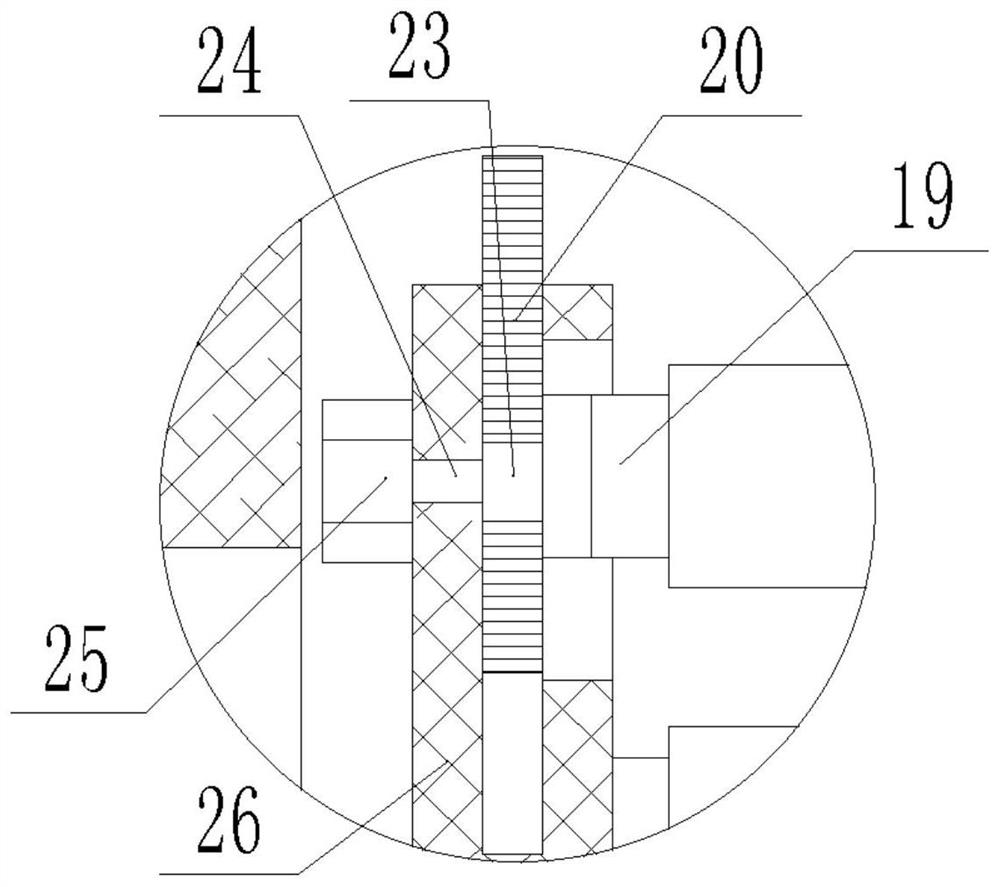

[0021] Such as Figure 1-3 As shown, a color steel tile pressing device that is convenient for cleaning the dust on the surface of the steel plate includes vertical plates 1 arranged parallel to the left and right, and a number of lower extrusion forming rollers 15 are horizontally arranged between the left and right vertical plates 1 from front to rear. Press molding roller 15 rotates between left and right vertical board 1, all rotates upper extrusion molding roller 14 just above each lower extrusion molding roller 15, and last extrusion molding roller 14 rotates between left and right vertical board 1, wherein An upper extruding roller 14 is coaxially connected with a rotating motor 11, and the rotating motor 11 is installed on the outer wall of the vertical plate 1, and a horizontal lifting plate 10 is arranged below the lower extruding roller 15, and the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap