Reverse fine cutting die and method for automotive specular metal decorating part

A technology for metal decoration and decorative parts, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve problems such as the cracking of the cutter edge and the core of the lower mold, affecting the mass production rate of the product, and the optical change of the product surface, etc., to achieve improvement Long service life, improve product appearance quality, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

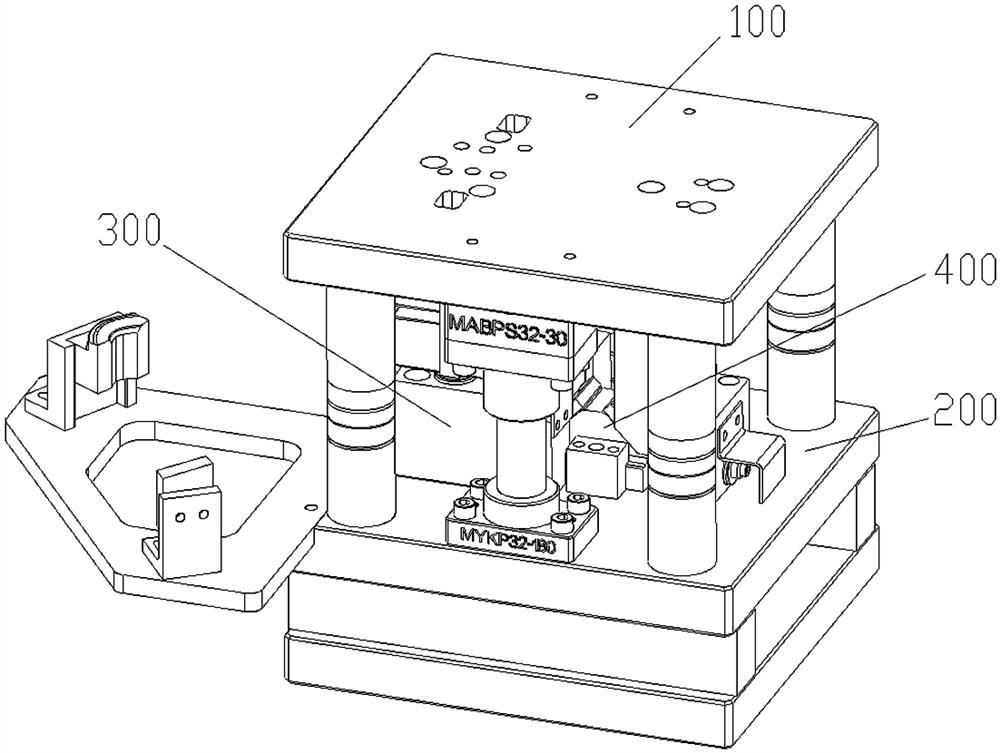

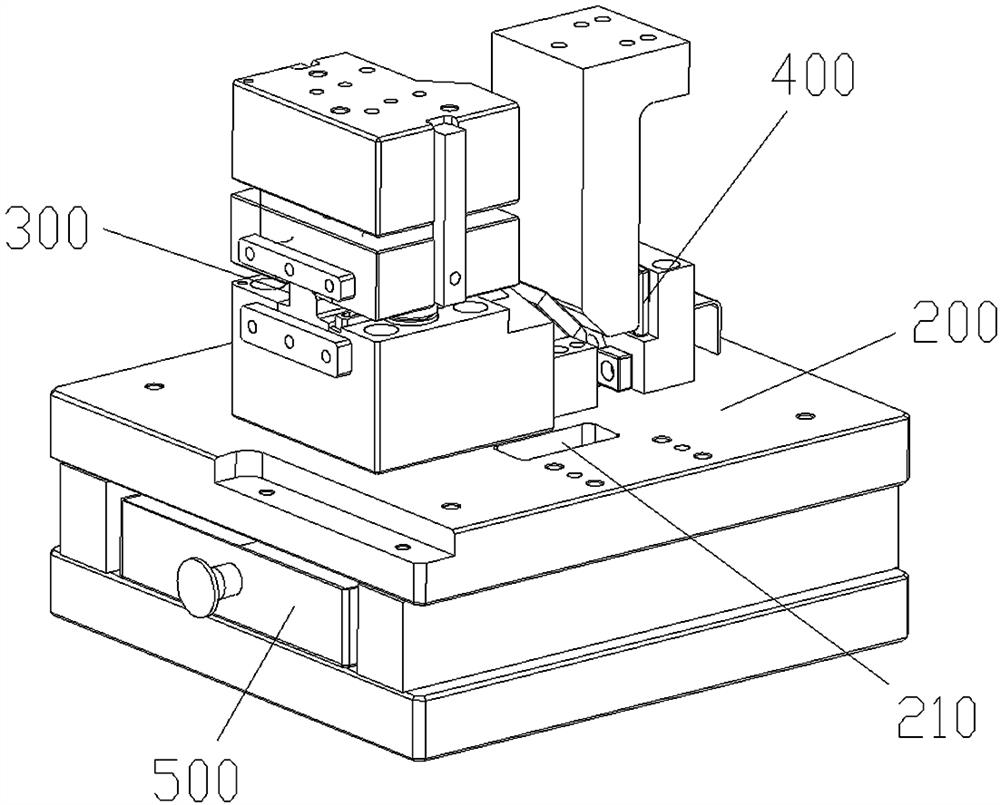

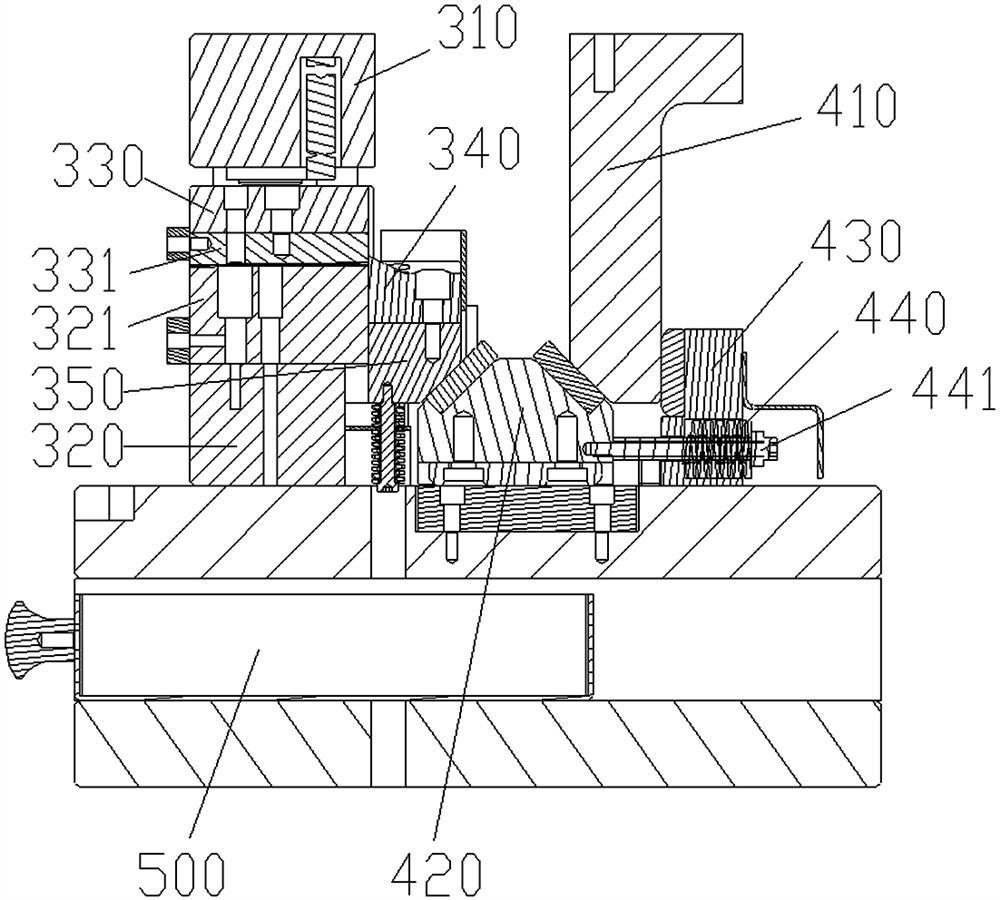

[0022] like Figure 1~6 As shown, a reverse fine-cutting mold for high-gloss metal decorative parts for vehicles includes an upper mold base 100, a lower mold base 200, a pressing material positioning mechanism 300, and a reverse wedge mechanism 400 located behind the pressing material positioning mechanism. The binder positioning mechanism 300 includes an upper mold holder 310 fixed on the lower side of the upper mold holder and a lower mold holder 320 fixedly installed on the lower mold holder. The mold core 321, the lower side of the upper mold fixing seat 310 is equipped with a binder seat 330, the lower side of the binder seat 330 is installed with a binder plate 331 for pressing the decorative parts, the binder plate is installed on the On the binder seat 330, the lower mold core is installed on the lower mold fixing base 320 through bolts and pins. The mechanism 400 controls the cutting knife 340 that rises to punch the end of the decorative part, and the processed pro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap