Horizontal plate spring assembly line

An assembly line and leaf spring technology, which is applied in the field of leaf spring assembly, can solve problems such as easy bumps, low assembly efficiency, and high labor intensity, and achieve the effects of reasonable structural design, high assembly efficiency, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

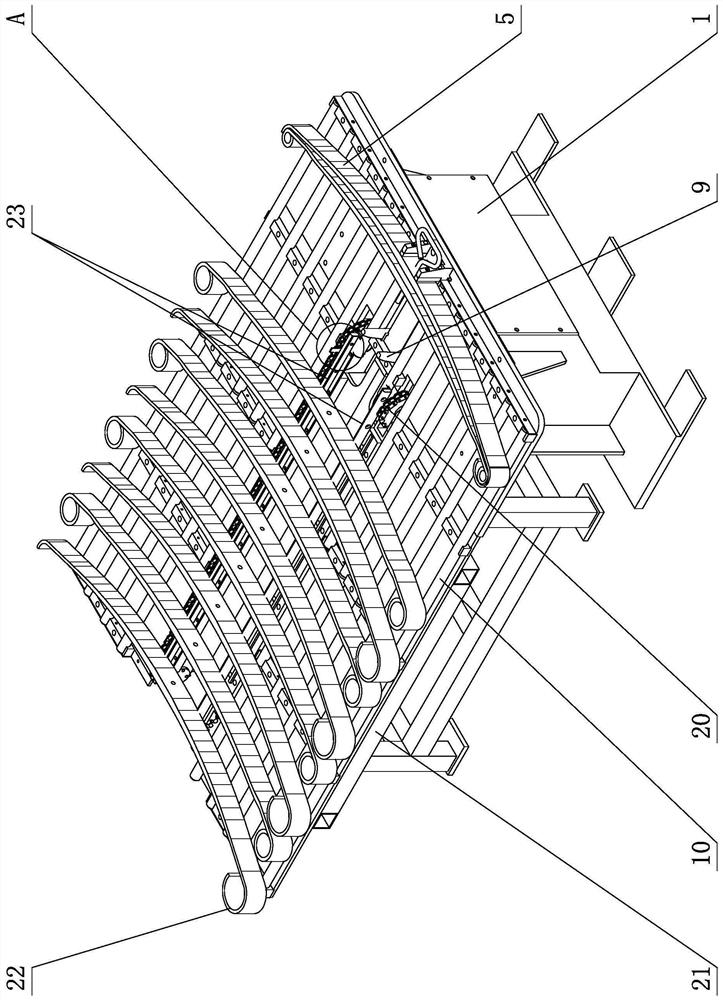

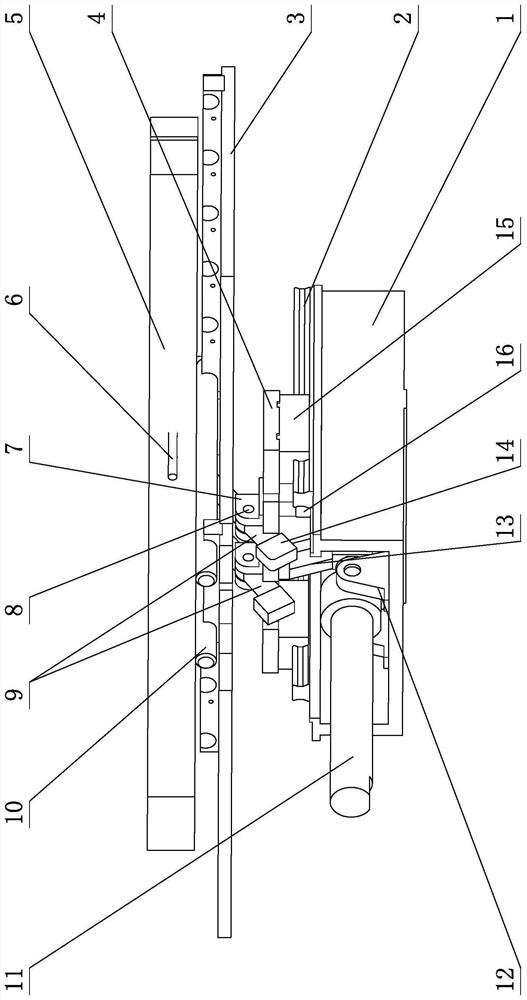

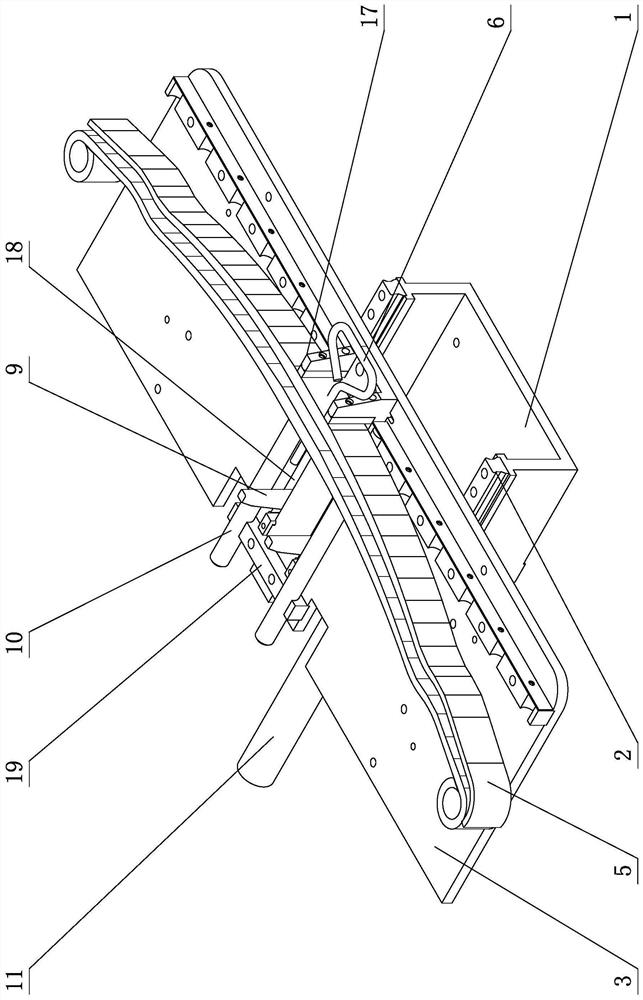

[0024] The present invention will be further described below in conjunction with accompanying drawing:

[0025] Such as Figure 1-Figure 5 , the horizontal leaf spring assembly line of the present invention includes a transmission mechanism and a clamping mechanism, the clamping mechanism is arranged at the transmission tail of the transmission mechanism; the transmission mechanism includes a transmission platform 21, and the upper surface of the transmission platform 21 is provided with a Transmission plate 23, one side of transmission plate 23 is provided with transmission unit, and transmission unit is provided with a plurality of transmission positioning plates 24, and the height of transmission plate 23 is higher than transmission unit, and the height of transmission positioning plate 24 top is higher than transmission plate 23.

[0026] In this example:

[0027] The transmission unit is a transmission chain 20, the transmission positioning plate 24 is arranged on one si...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap