Fluted disc rotating positioning mechanism of milling cutter processing machine

A positioning mechanism and processing machine technology, applied in metal processing mechanical parts, positioning devices, precision positioning equipment and other directions, can solve the problem of low rotation accuracy of the clamping device, avoid frequent debugging of the machine, avoid tooth damage, transmission effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

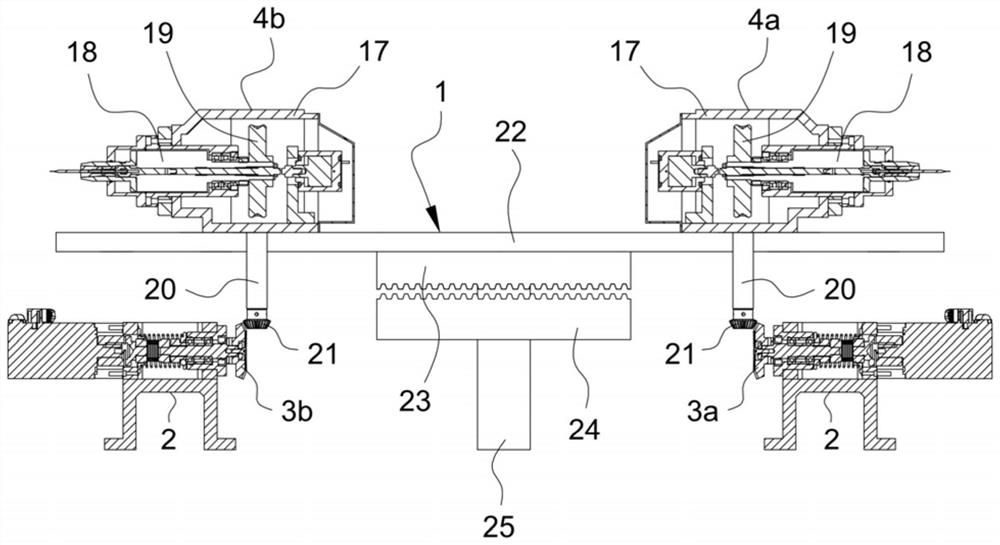

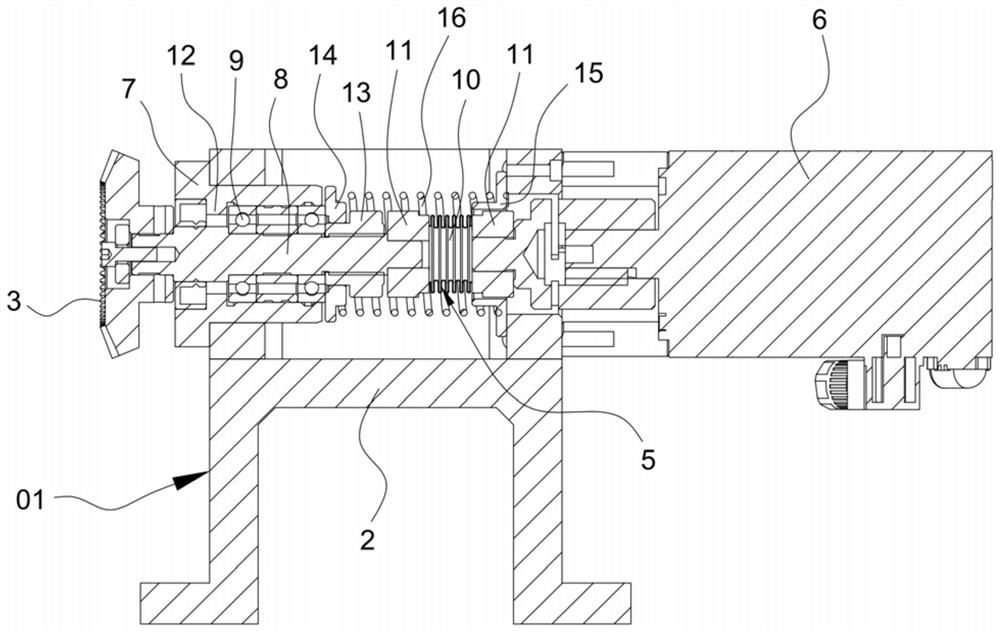

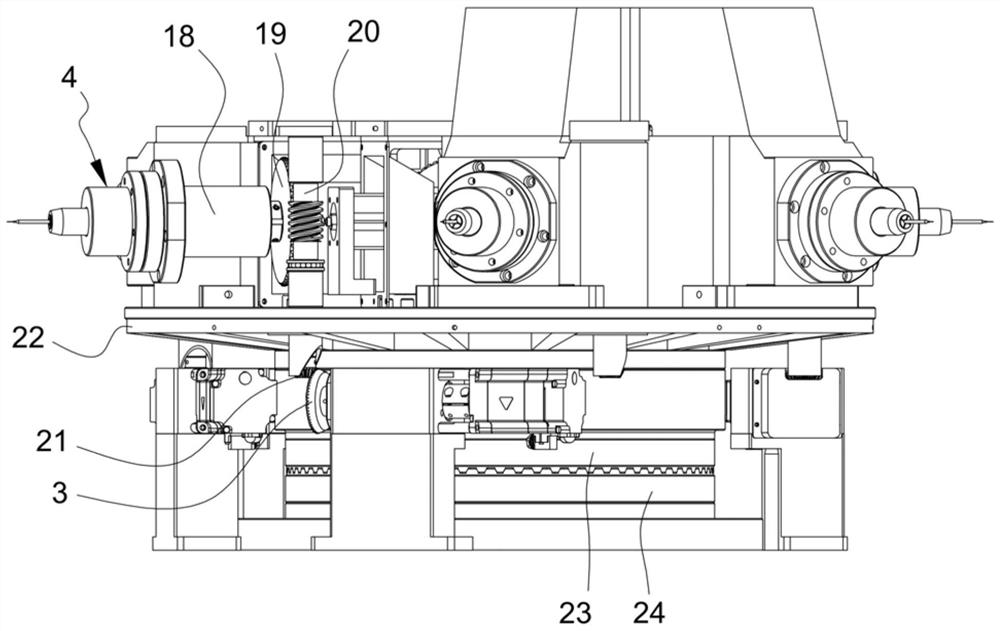

[0026] Such as Figure 1 to Figure 5 As shown, the tooth plate rotation positioning mechanism of a milling cutter processing machine provided by the present invention includes a rotary table 1, a gear elastic rotation drive device 01 and a plurality of clamping devices 4 arranged on the rotary table 1, and the gear The elastic rotation drive device 01 includes a drive base 2 and a first gear 3 that is rotatably mounted on the drive base 2. An elastic connector 5 is installed on one end of the first gear 3, and the elastic connector 5 is connected with a rotation driver 6. The rotation driver 6 Used to drive the elastic connecting member 5 and the first gear 3 to rotate, the first gear 3 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com