Turbine blade assembling method

An assembly method and technology of turbine blades, which are applied to the supporting elements of blades, engine elements, machines/engines, etc., can solve the problems of time-consuming and laborious assembly, large assembly force, gas turbine failure, etc., so as to avoid tooth damage and improve assembly quality. , Eliminate the effect of scrap parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] A method for assembling a turbine blade of a gas turbine, comprising the following steps:

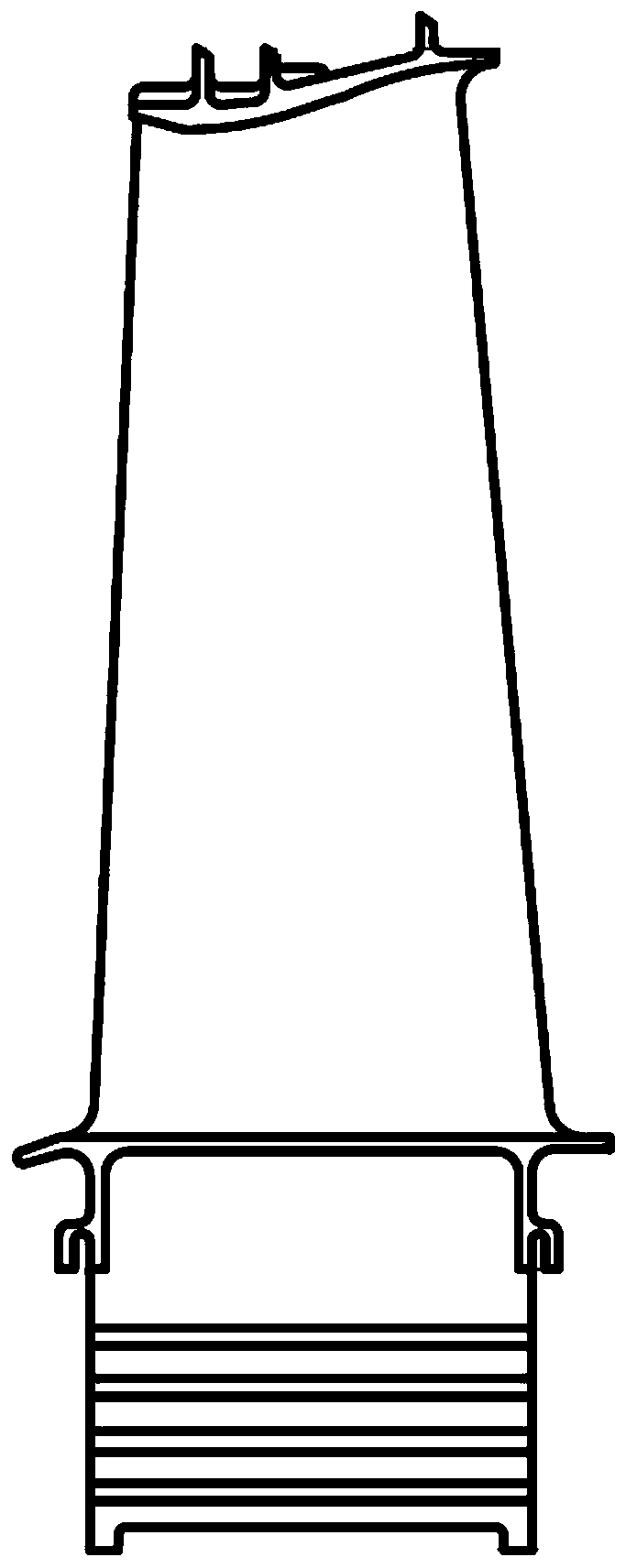

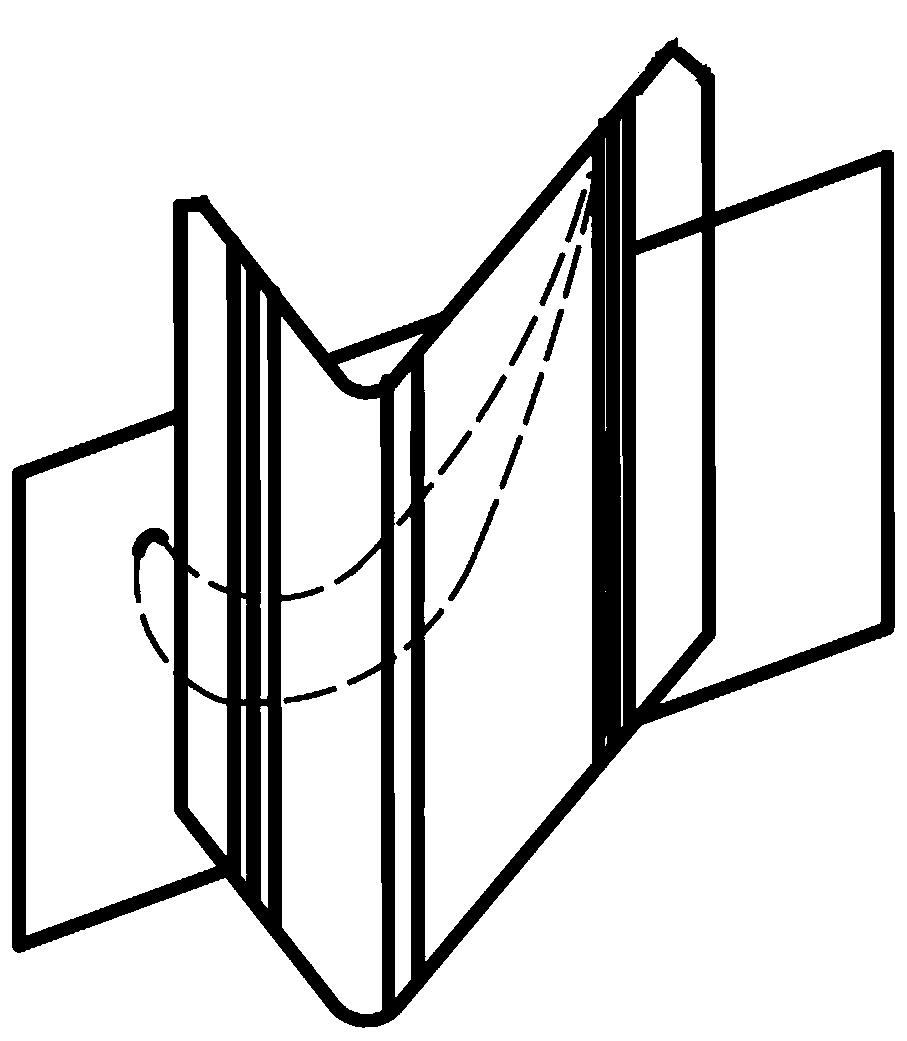

[0047] Step 1: Weigh the blade on an electronic balance; the shape of the blade is as figure 1 and figure 2 As shown; the crown is serrated, and the lengths of the two serrations of the crown are inconsistent, the design structure is pre-twisted during assembly, and the long and short sides of the crown of the blade are mutually constrained;

[0048] Step 2: Sort the leaves according to weight, the heaviest leaf is No. 1, and sort them in order;

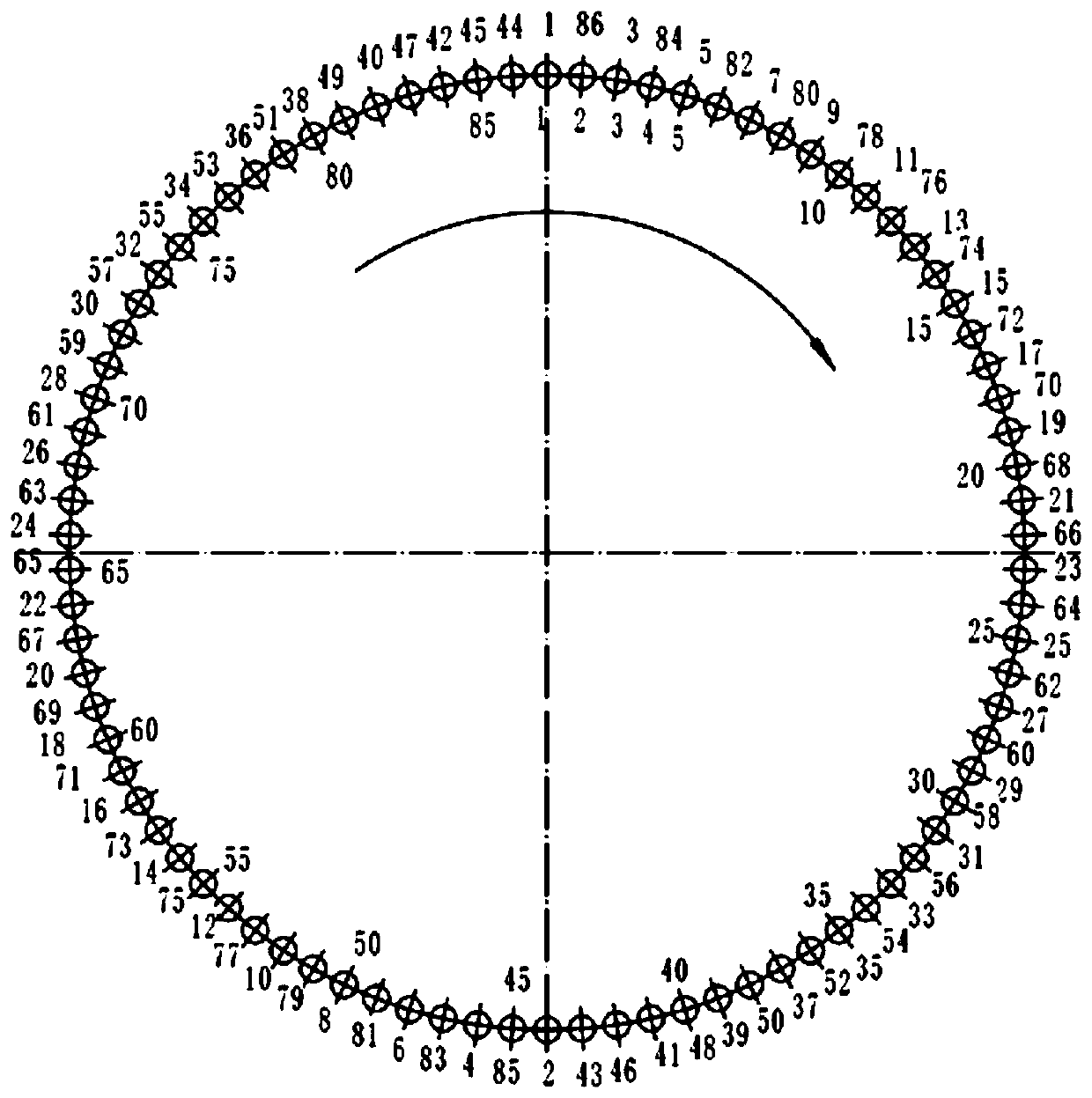

[0049] Step 3: Follow the image 3 Correspondence Put the blades into the corresponding turbine disk tenons, and check the swing of a single blade, image 3 The serial number of the inner ring is the serial number of the roulette slot, and the serial number of the outer ring is the serial number of the blade weight, and the swing amount should not be less than 0.25% of the blade length.

[0050] Step 4: Repeat step 3 to check the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com