Rotary control center mechanism of multi-station milling cutter machining machine

A control center and processing machine technology, which is applied in the direction of metal processing machinery parts, metal processing equipment, milling machines, etc., can solve problems such as slipping, easy tooth damage, scratching milling cutter rods, etc., so as to avoid debugging the machine and prolong its use The effect of life expectancy and labor cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]In order to facilitate the understanding of those skilled in the art, the following description of the invention will be made in conjunction with the drawings, and the contents mentioned in the present invention are not limited.

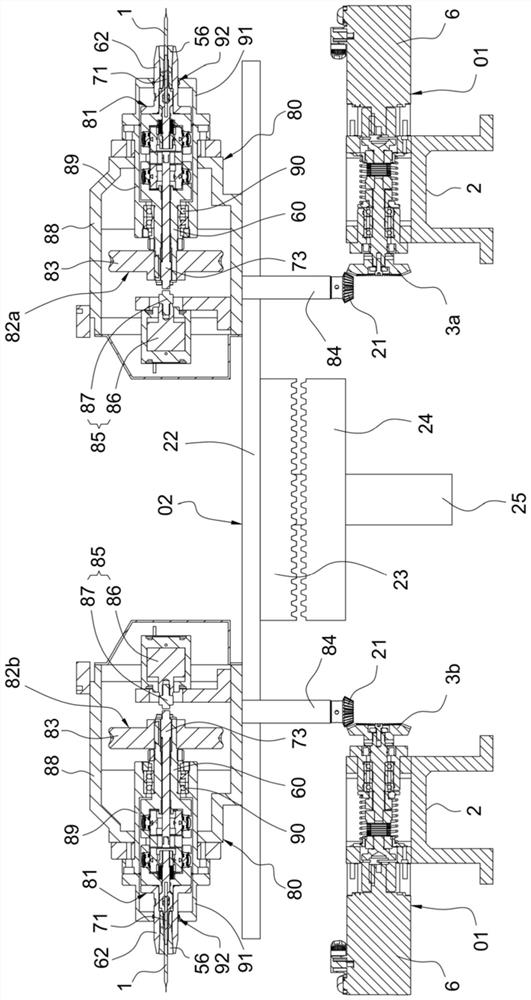

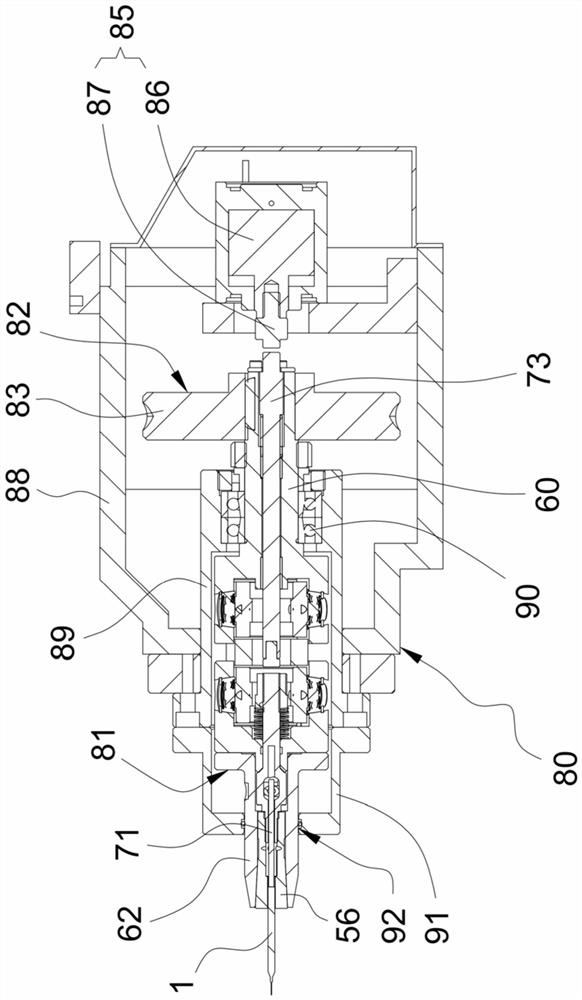

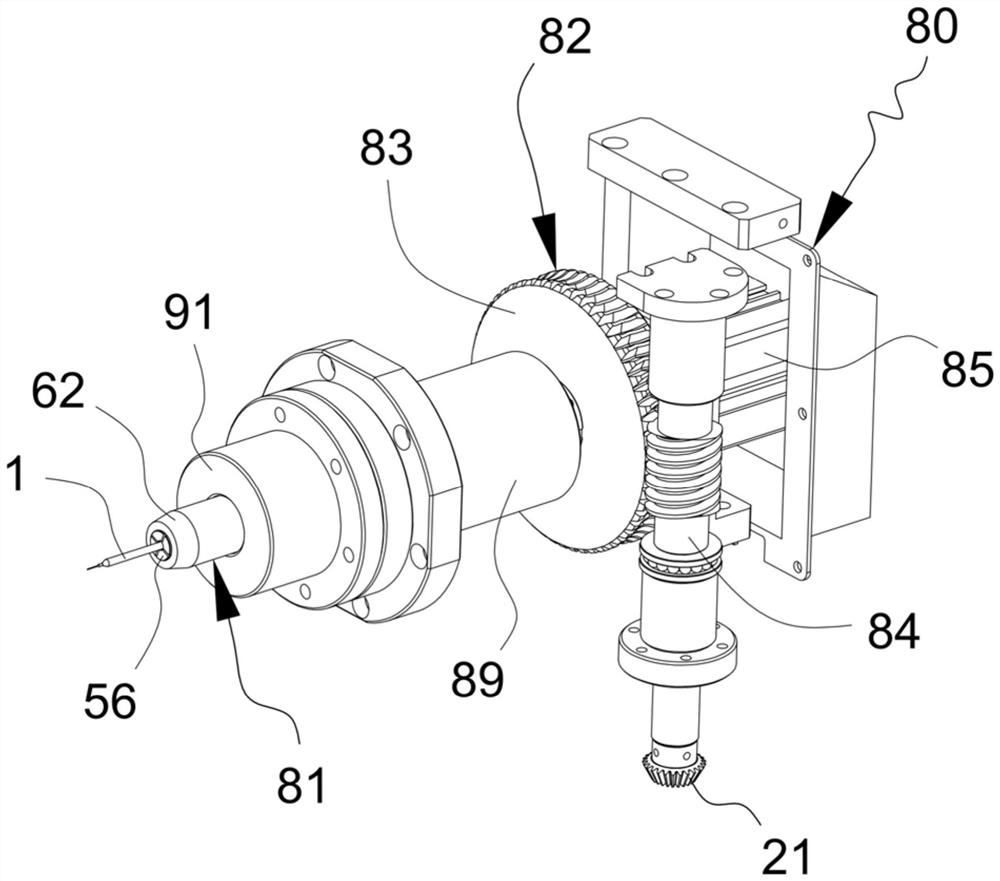

[0040]Such asFigure 1 to 15As shown, a rotational control center mechanism of a multi-station milling cutter, including a rack 39, a turntable device 02, a plurality of universal jaw rotation structures 80 and a plurality of gear elastic rotation drive structures 01 The turntable apparatus 02 includes a sliding rotation of the working table 22, which is fixed to the lower end of the working table 22, fixed to the first tooth disk disposed at the lower end of the workbed plate 22. The second tooth disk 24 meshed with the first tooth disc 23 and the table drive assembly 25 driven by the support shaft 29, and the support shaft 29 is provided with a sliding rotating member 40, and the table drive assembly 25 is used to drive support. The shaft 29 is slid in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com